Double-row swallow-tail sealing structure of roller bit

A sealing structure, roller cone bit technology, applied in construction and other directions to achieve the effect of reducing friction and stress concentration and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

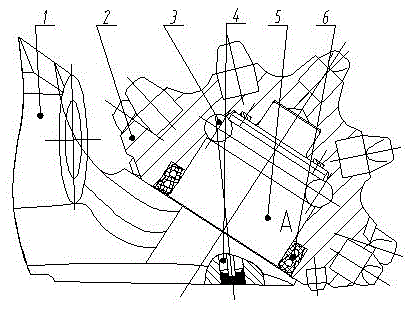

[0010] Such as figure 1 As shown: the claw 1 and the cone 2 are respectively socketed on the bearing 5 through the inner hole of the cone, the steel ball 3 is put into the bearing through the pin hole, and the plug 4 is welded and fixed, and the cone 2 is held by the steel ball 3 on bearing 5. A double-row dovetail sealing ring 6 is arranged between the cone 2 inner hole and the bearing 5 .

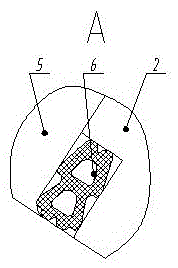

[0011] Such as figure 1 , 2 As shown, a double-row dovetail sealing structure of a roller cone bit in the present invention is composed of a roller cone 2, a bearing 5, and a double-row dovetail sealing ring 6; the double-row dovetail sealing ring 6 is a combination of two dovetail sealing rings. , the bottom surface is a large end surface, and the top surface is a small end surface, which improves the self-sealing performance, increases the stability of the seal, and prevents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com