Vibration response characteristic and wave trough control-based vibration input spectrum parameter determination method

A vibration response and determination method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as loss of product life, instrument fatigue, etc., to avoid premature loss, avoid overstress screening, The effect of reducing hidden dangers of product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

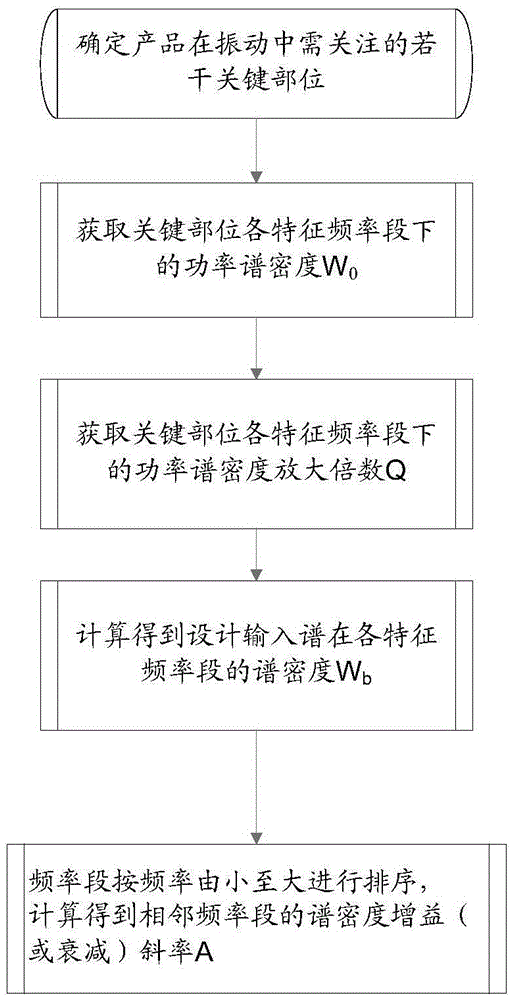

[0022] like figure 2 Shown, the realization process of the present invention is described in detail below:

[0023] 1) Determine some key parts of the product that need to be paid attention to during vibration according to the product characteristics;

[0024] According to the different characteristics of different products, determine the parts that need to be paid attention to in the vibration. Here, we mainly focus on the parts that are easy to be damaged in the vibration and the parts that need to be inspected in the vibration.

[0025] Taking the inertial group product as an example, the inertial instrument, signal processing and interface circuit are the key components of the product, and special attention needs to be paid to whether its quality is reliable.

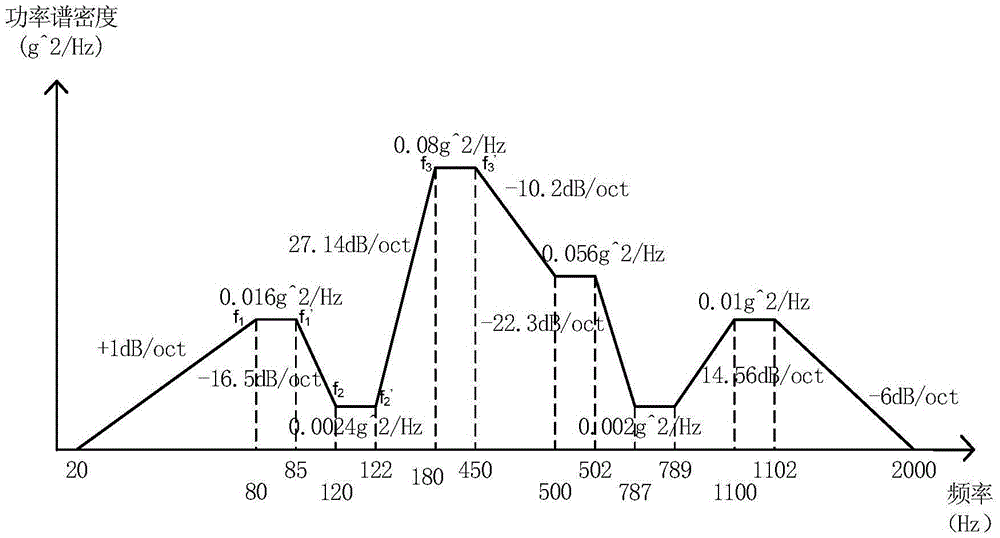

[0026] 2) Obtain the peak frequency section and trough frequency section of the vibration response curve of key parts by means of test measurement or simulation, collectively referred to as the characteristic freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com