Boiling galls and drinking equipment

A technology for boiling tanks and inner tanks, which is applied in beverage preparation devices, kitchen utensils, household appliances, etc. It can solve the problems that the external sensor cannot accurately detect the water level of the boiling tank and cannot accurately control the water level of the boiling tank, and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] The invention provides a boiling tank, which is applied to drinking water equipment (such as water dispensers, clean drinking machines, direct drinking machines and pipeline machines).

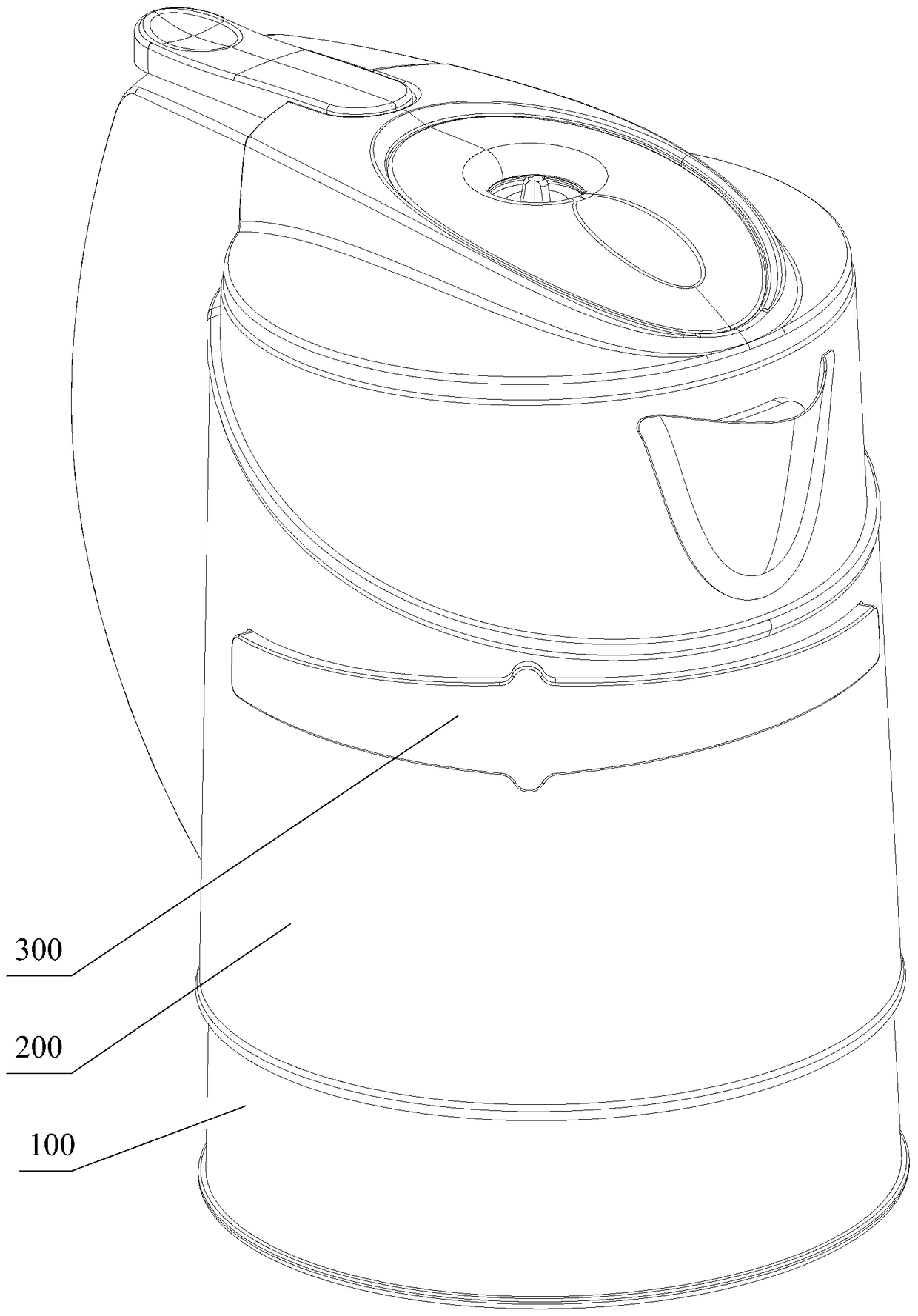

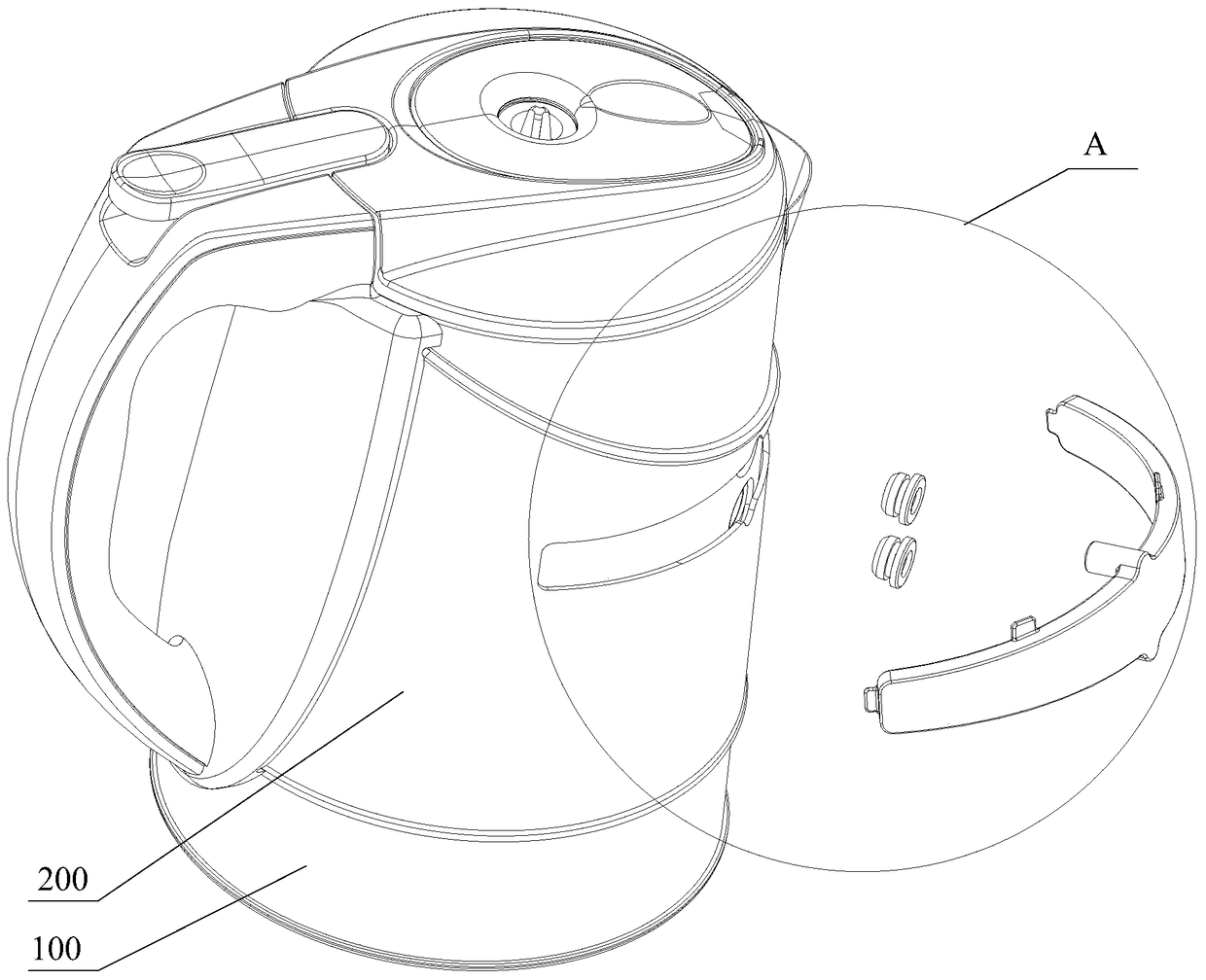

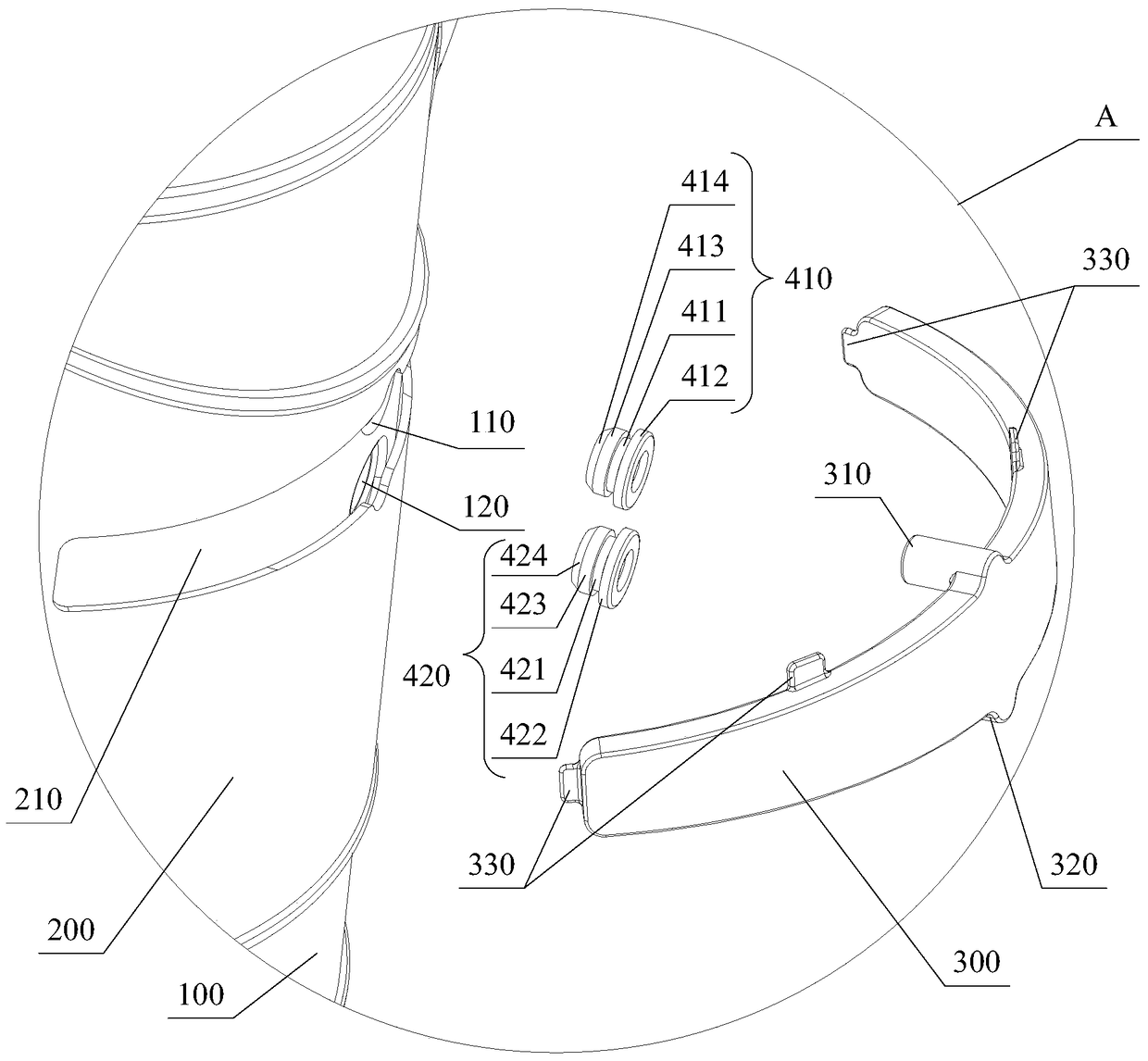

[0025] refer to figure 1 , figure 1 It is a structural schematic diagram of a preferred embodiment of the boiling gallbladder of the present invention.

[0026] In a preferred embodiment of the present invention, the boiling tank includes a heating inner tank 100, and an anti-scald protection shell 200 sleeved on the upper part of the heating inner tank 100, and the boiling tank also includes a non-metallic horizontal water gauge installed on the anti-scalding protection shell 200 300, the non-metal horizontal water gauge 300 communicates with the inside of the heating liner 100.

[0027] In this embodiment, a non-metallic h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com