Control system for tapping and processing lamp covers of LED lamps

A technology of LED lights and control systems, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of unguaranteed drilling position accuracy and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

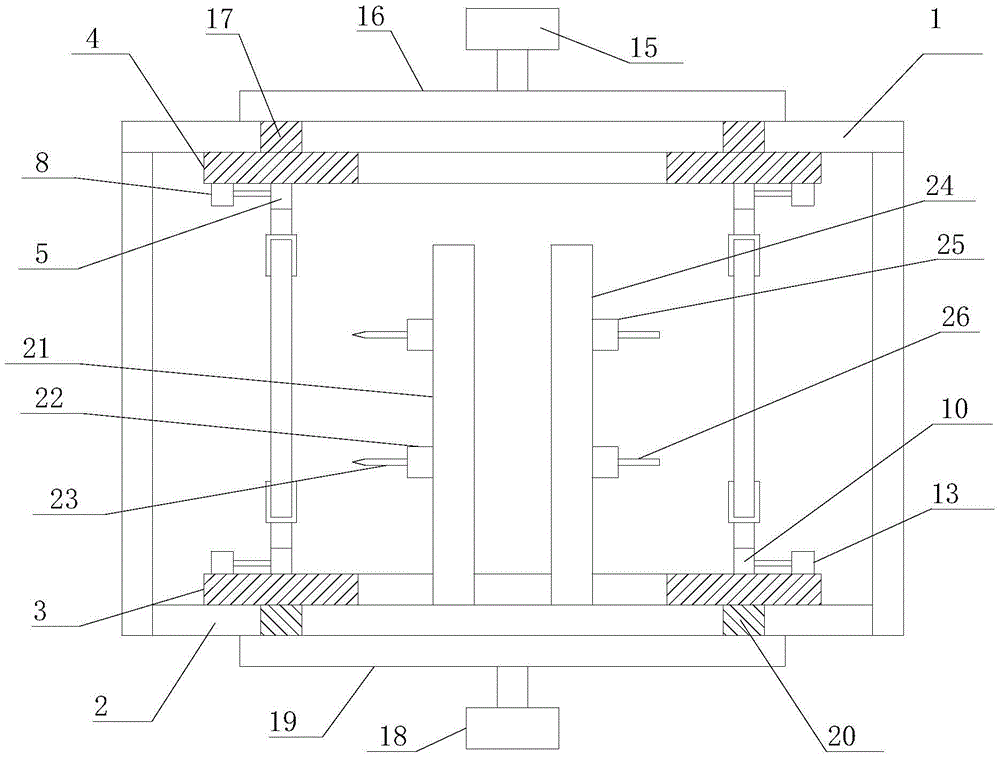

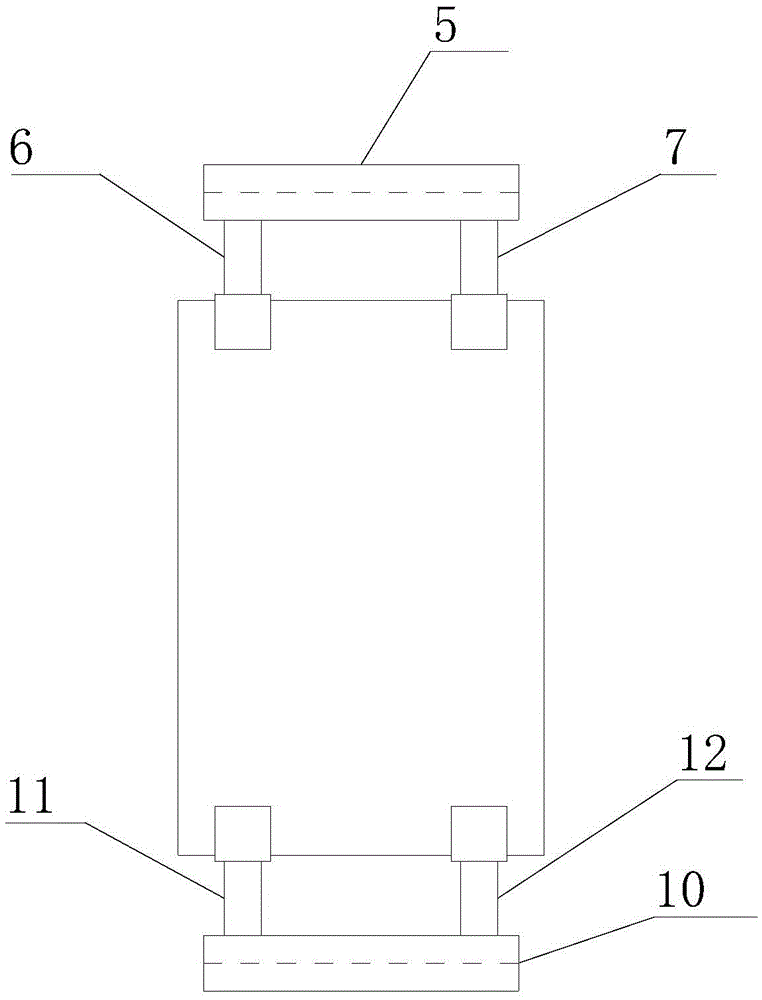

[0018] refer to figure 1 , figure 2 , the present invention proposes a tapping processing control system for LED lamp cover, including a first work frame 1, a second work frame 2, a clamping mechanism, a drilling and tapping mechanism, a plurality of first driving mechanisms 22, a plurality of A second driving mechanism 25, a plurality of third driving mechanisms 8, a plurality of fourth driving mechanisms 13, a fifth driving mechanism, a sixth driving mechanism, a first distance sensor, a second distance measuring sensor, a control mechanism, wherein:

[0019] Both the first work frame 1 and the second work frame 2 are set horizontally, the first work frame 1 is located above the second work frame 2, a tapping processing area is formed between the first work frame 1 and the second work frame 2, and the clamping mechanism , Drilling and tapping mechanism are located in the tapping processing area.

[0020] The clamping mechanism includes a first annular turntable 3, a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com