Calender roll unit of a super calender

A super calender and calender roll technology, applied in the field of papermaking equipment, can solve the problems of large calender rolls and paper guide rolls, hindering paper grades, and large difference in quality index and banner, so as to reduce processing difficulty and intermediate problems. Less, less movement space change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

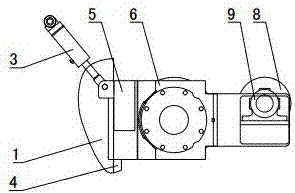

[0036] Such as Figure 1~2 As shown: two guide rails 4 are arranged on the super calender frame 1, and the two guide rails 4 are arranged vertically, and the cross sections of the two guide rails 4 are both "T" shaped. The guiding device is a sliding seat 5, which is provided with a "T" shaped chute, and the sliding seat 5 is installed on the guide rail 4 through the chute, and can slide up and down along the guide rail 4.

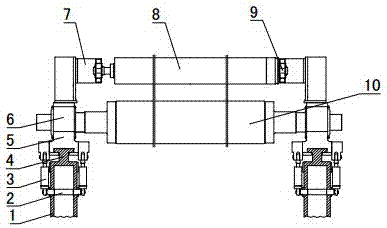

[0037] Both ends of the calender roll 10 are fixed on the sliding seat 5 through the calender roll bearing housing 6 . A paper guide roller mounting frame 7 is installed on the two calender roller bearing seats 6, and a paper guide roller bearing seat 9 is arranged on each paper guide roller mounting frame 7, and both ends of the paper guide roller 8 are installed on the paper guide roller. Roller chock 9. The axes of the calender roll 10 and the paper guide roll 8 are parallel, and the outer surface of the calender roll 10 is spaced from the outer surfa...

Embodiment 2

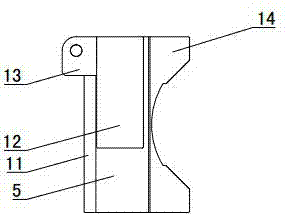

[0064] Such as Figure 7~8 As shown: the difference between embodiment 2 and embodiment 1 is that: the paper guide roller installation frame 7 is installed on the connecting plate 12 on one side of the sliding seat 5 through bolts, so that the paper guide roller 8 and the calender roller 10 are respectively located on the sliding seat 5, the axes of the paper guide roll 8 and the calender roll 10 are arranged in parallel, and the axes of the paper guide roll 8 and the calender roll 10 are parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com