Slide seat of super calender and super calender

A super calender and sliding seat technology, applied in the field of papermaking equipment, can solve the problems of many processing and operation processes, collision of calender rolls, damage to calender rolls, etc., to achieve small changes in movement space, convenient purchase and accessories, The effect of convenient and precise installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

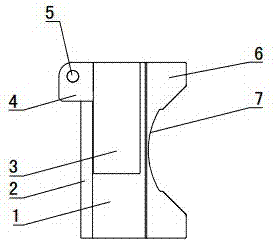

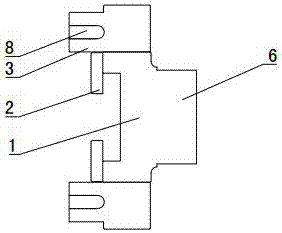

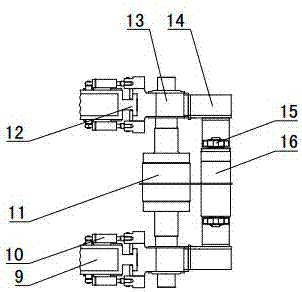

[0036] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0037] A slide for a super calender, comprising a slide main body 1, on which a connecting plate 3 for connecting a balance oil cylinder 10 and a calender roll installation part 6 for installing a calender roll 11 are provided; the slide base The main body 1 is provided with a guide part that cooperates with the guide mechanism. The slide body 1 of the super calender is provided with a calender roll installation part 6, the calender roll 11 can be installed on the slide body 1, and the connecting plate 3 can be connected with the balance oil cylinder 10, so that the calender roll 11 The gravity is balanced, and the guide part guides the movement of the main body of the sliding seat 1, so that the main body of the sliding seat 1 maintains a linear motion. Compared with the swing arm type, the movement space of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com