Super calender

A super calender and calender roller technology, applied in the field of papermaking equipment, can solve many problems in the processing and operation process, calender rollers collide with each other, damage the calender roller and other problems, and achieve small changes in the movement space and intermediate problems The effect of less and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

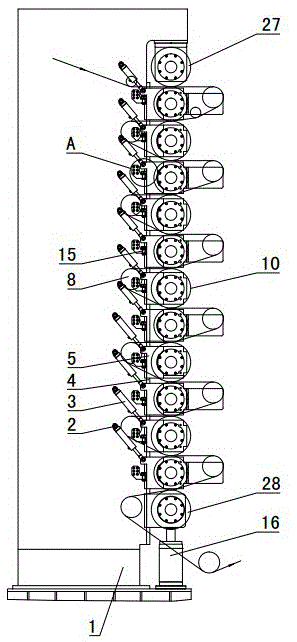

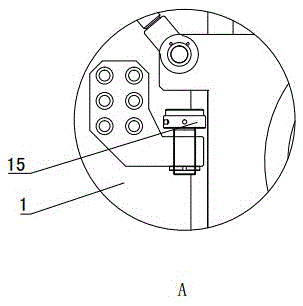

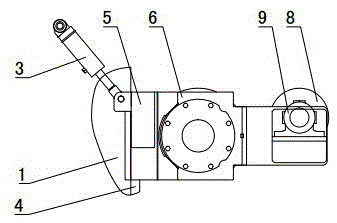

[0044] Figure 1~16 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~16 The present invention will be further described.

[0045] A super calender, comprising a frame 1, on which a vertical guide mechanism is arranged, a calender roller 10 and a paper guide roller 8 are slidably connected to the guide mechanism through a sliding seat 5, and the frame 1 is provided with a For the gravity balance system that balances the gravity of the calender rolls 10, a bottom pressing device is provided under the lowermost calender roll 10, and the bottom pressing device pushes each calender roll 10 up and presses the calender roll 10 , The calender roll 10 is quickly off the roll under the action of gravity. The gravity balance system of the super calender can balance the weight of the calender roll 10, so that the pressure of the lower nip and upper nip of the super calender on the paper web can be controlled, and the difference between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com