Heat dissipation apparatus for motors

A heat dissipation device and motor technology, applied in electromechanical devices, cooling/ventilation devices, parts of pumping devices for elastic fluids, etc., can solve problems such as increasing air volume, reducing motors, and not improving the cooling effect of fans significantly , to achieve the effect of increasing the air intake, improving the air intake and motor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the structure, combination and features of the present invention in detail, specific embodiments are listed below with accompanying drawings, so that those skilled in the art can understand the technical content of the present invention. However, the given examples are only used to illustrate examples, not to limit the present invention.

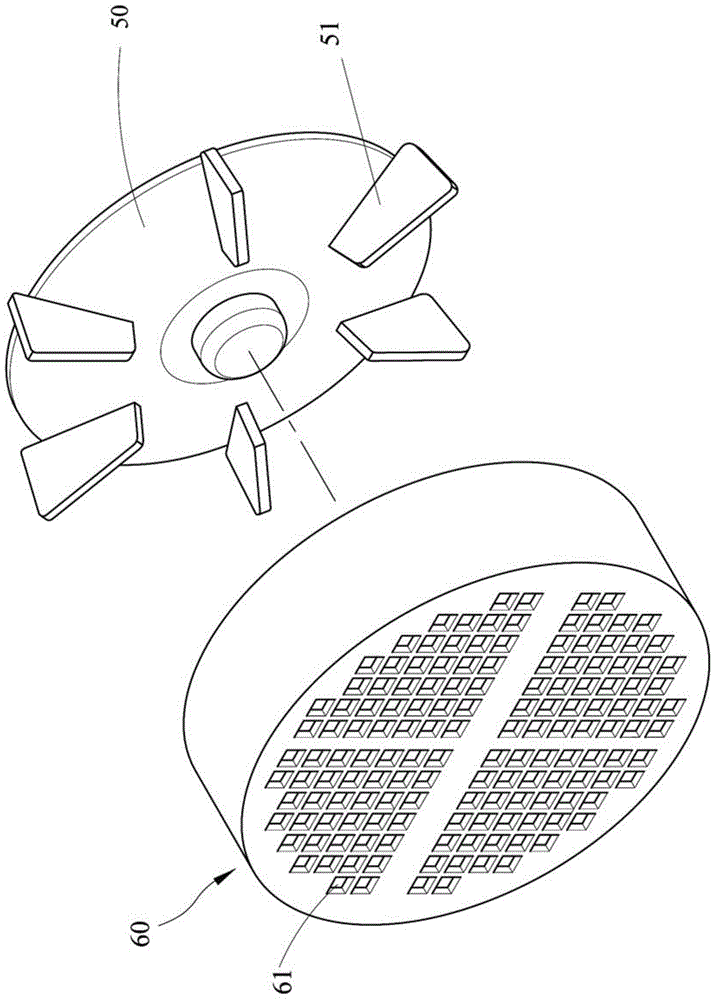

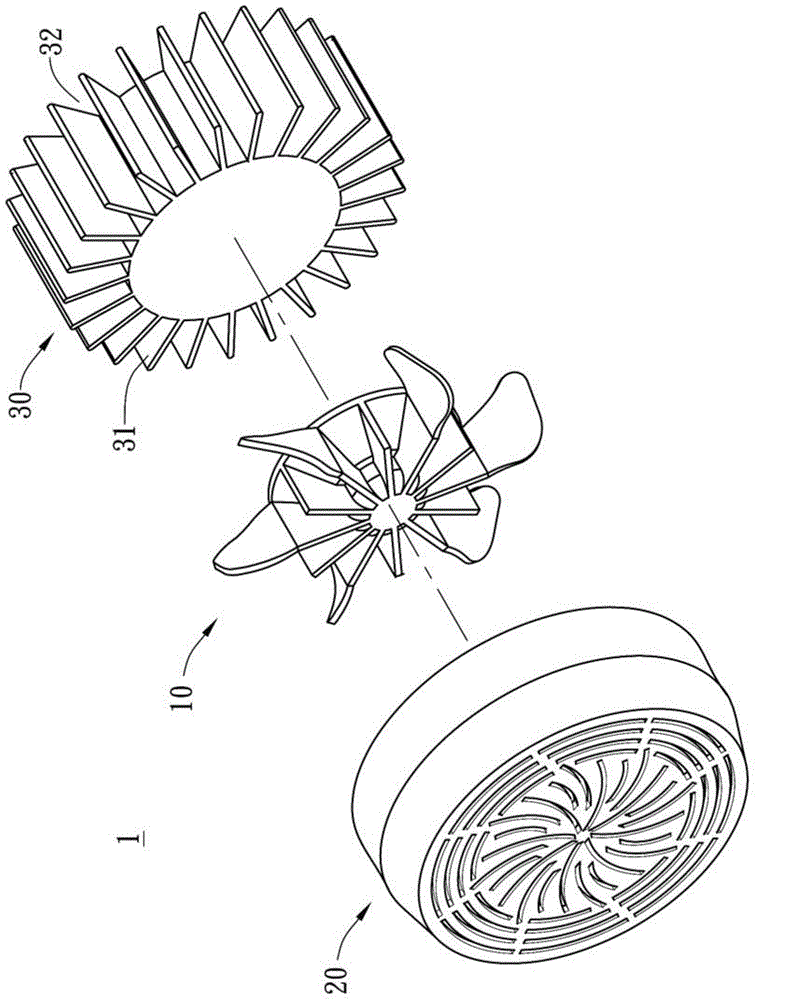

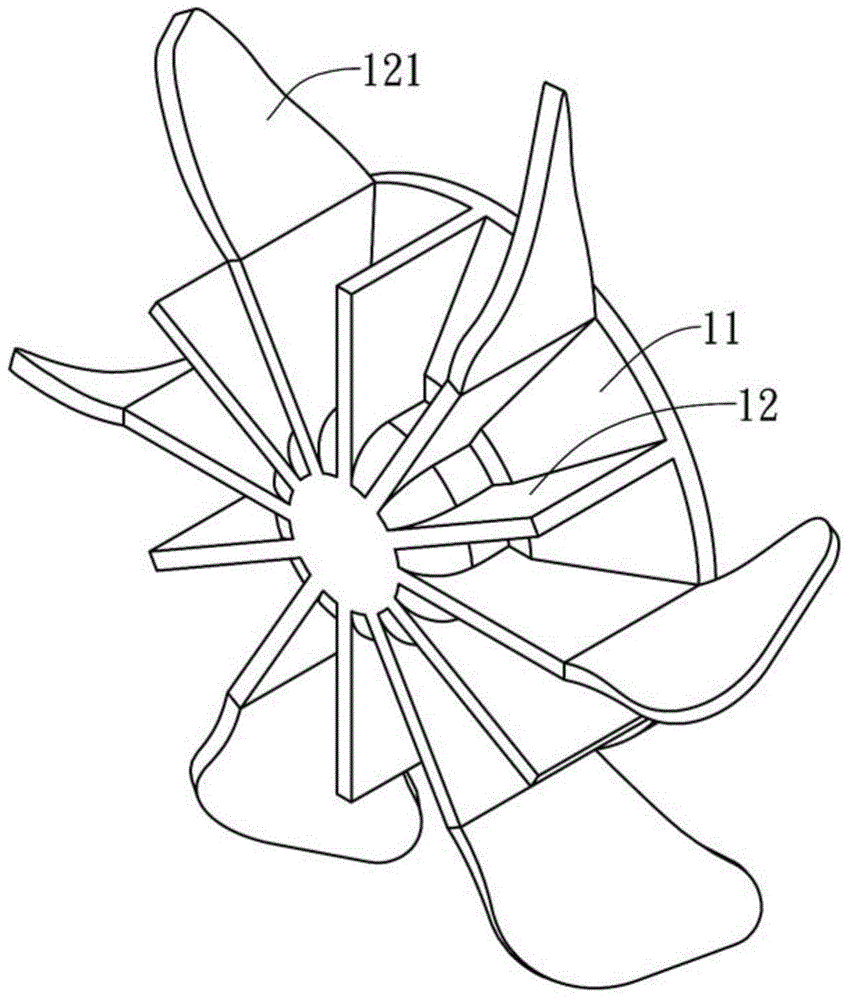

[0035] Please refer to attached image figure 2 As shown, it is a combined diagram of the motor heat dissipation device 1 of the present invention installed on a motor 30 , which includes a heat dissipation fan 10 and a wind deflector 20 . Another example image 3 As shown, wherein, the cooling fan 10 has a back plate 11, and a plurality of fan blades 12 and a plurality of peripheral blades 121 located at the outer ends of the fan blades 12; wherein, the plurality of fan blades 12 are arranged in a centrifugal radial structure One side of the backboard 11 , that is, the fan blades 12 are radially arranged and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com