Backlight module

A technology of backlight module and backplane, which is applied in the direction of optics, light source, point light source, etc., can solve the problem of not being able to meet the requirements of the backlight module, and achieve the effect of reducing the amount of materials used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

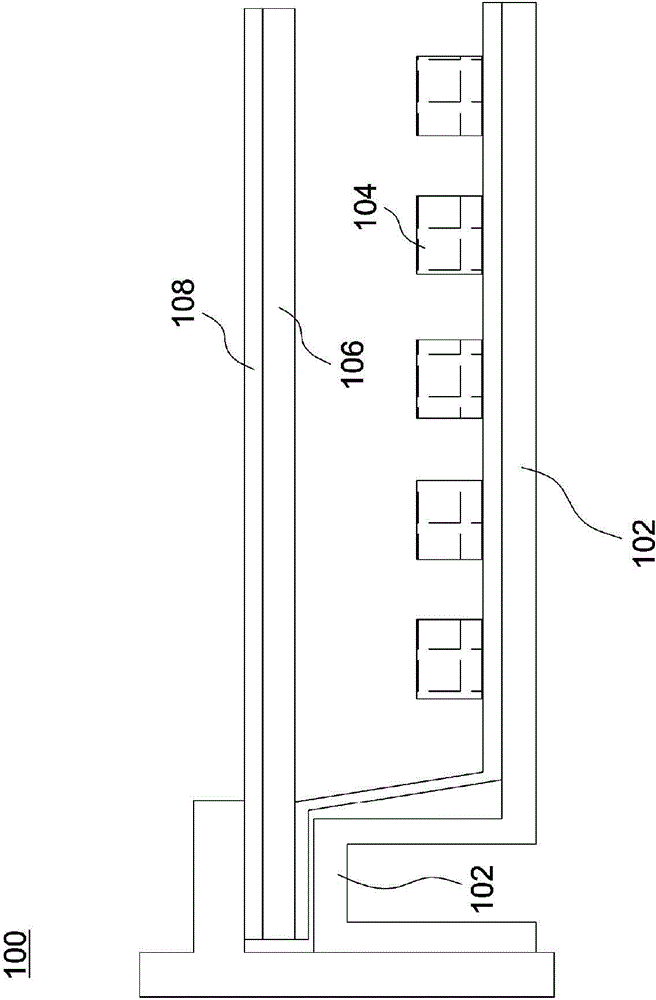

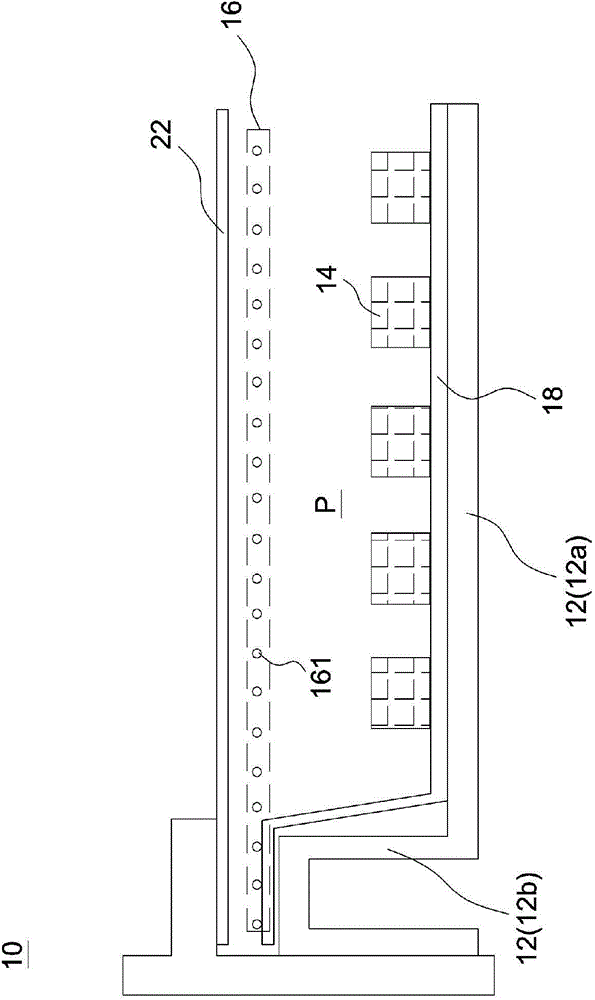

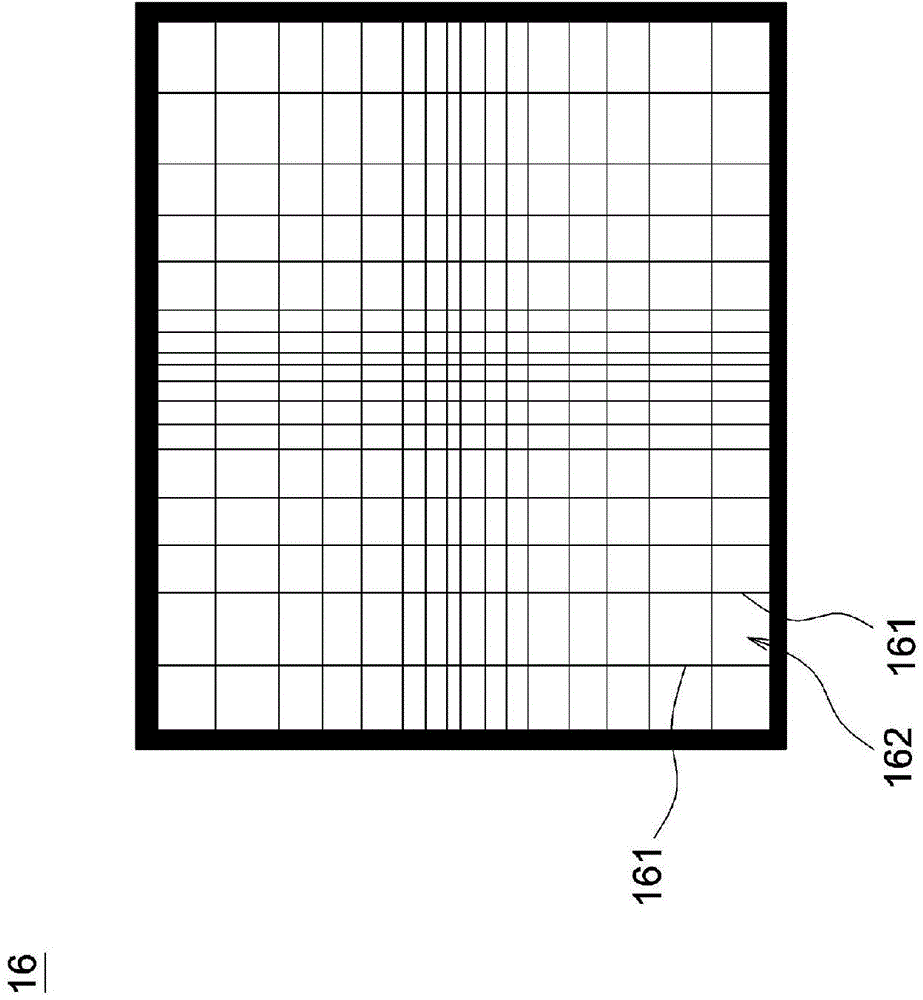

[0017] figure 2 It is a schematic partial cross-sectional view of a backlight module according to an embodiment of the present invention. Such as figure 2 As shown, a backlight module 10 includes a backplane 12 , at least one light source 14 , and a mesh diffusion structure 16 . The backplane 12 includes a baseboard 12a and a plurality of sidewalls 12b ( figure 2 Only one side wall 12b is shown in the figure, and the multiple side walls 12b are connected to the bottom plate 12a and form an accommodating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com