A detection method for automobile front frame assembly inspection tool

A front-end framework and detection method technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of low efficiency, poor space utilization, low safety, etc., achieve reasonable use of space, simple operation, and improve detection quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

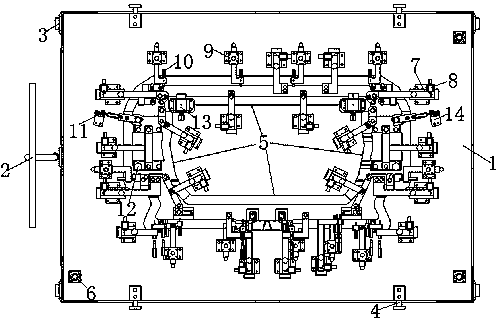

[0036] combine figure 1 , the detection method of a kind of automobile front frame assembly inspection tool of the present embodiment, its steps are as follows:

[0037] Step 1: Put the front-end frame on the detection surface 5 of the inspection tool, align the main and auxiliary positioning of the front-end frame with the main and auxiliary positioning mechanisms of the inspection tool, and insert the positioning pins on the inspection tool into the positioning holes in sequence to ensure The positioning of the front-end frame in the left-right, front-back directions;

[0038] Step 2: Press down the first pliers 11 and the second pliers 14 in sequence, and press the front-end frame through the main and auxiliary positioning mechanisms of the inspection tools on the first pliers 11 and the second pliers 14, so that the front-end frame and The detection profiles of the inspection tool are fitted together to ensure the positioning of the front frame in the up and down directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com