A concrete tie rod arch bridge suspender lower anchor end connection structure and its construction method

A technology for tied arch bridges and connecting structures, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of anchor end structure corrosion, inconvenient replacement of booms, breakage of booms, etc., to extend service life and strength, and facilitate real-time The effect of maintenance and avoidance of rust and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

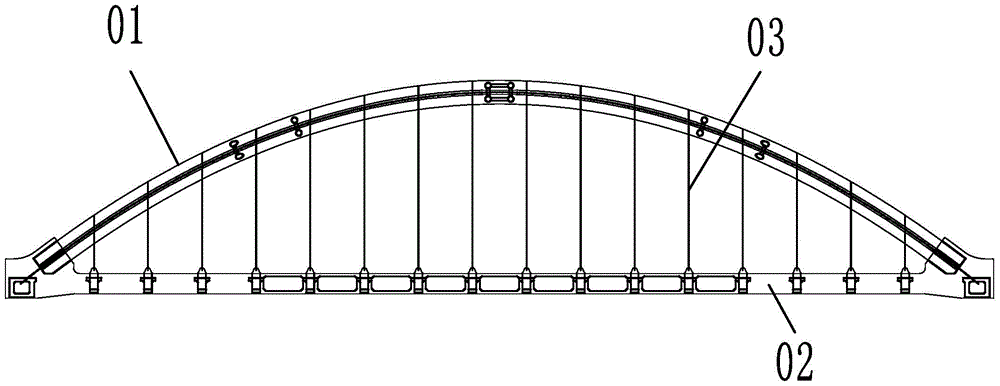

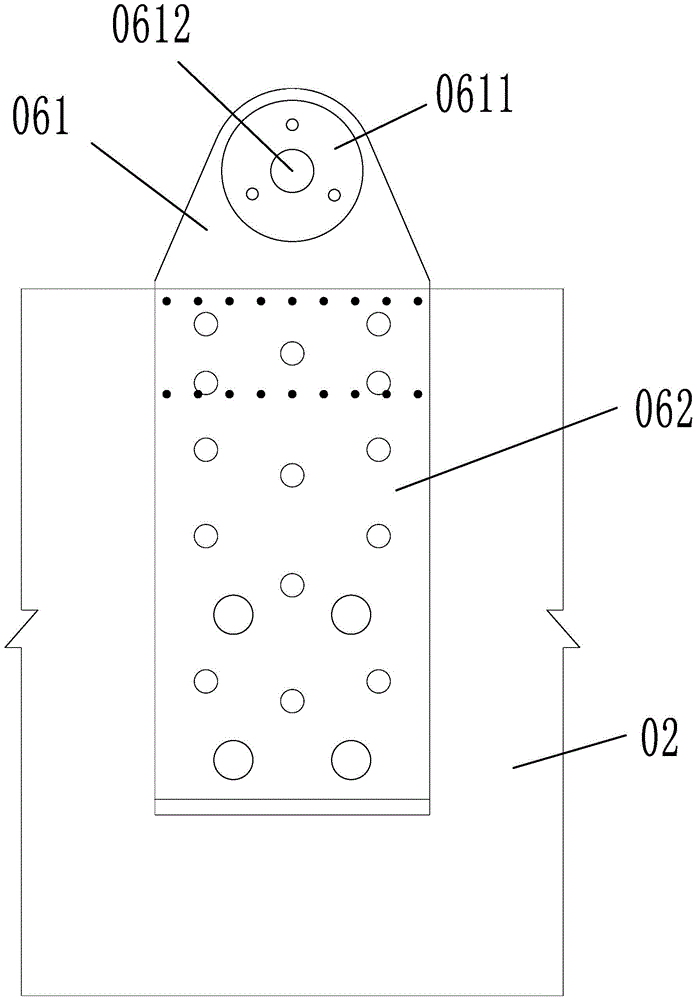

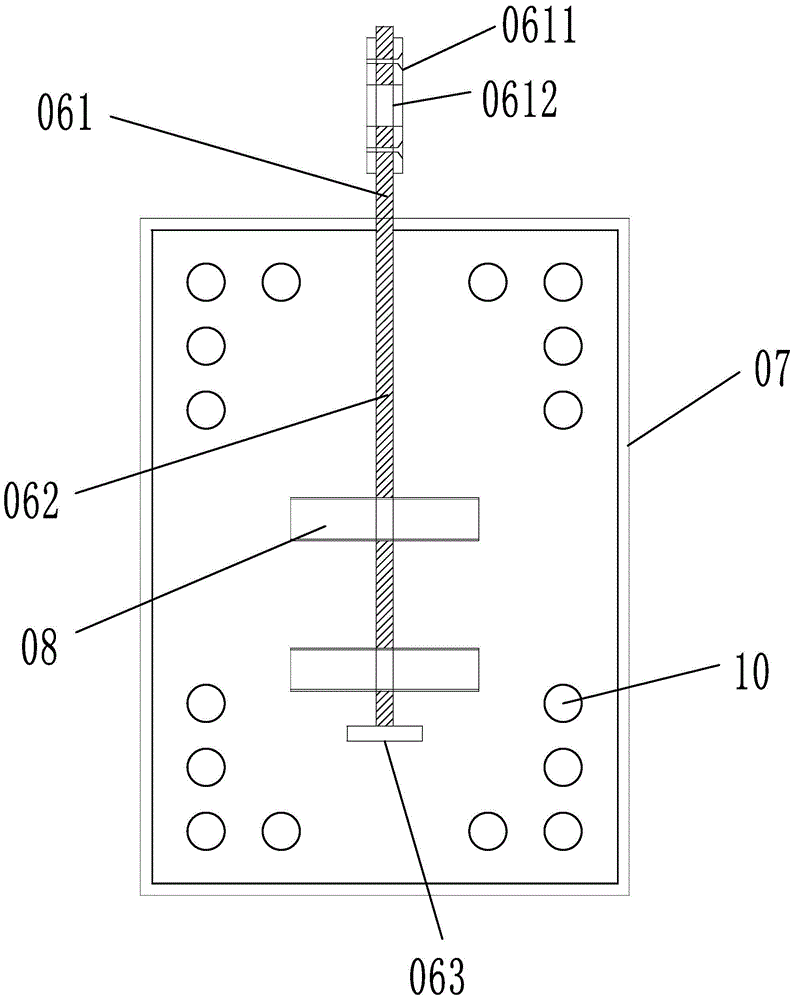

[0031] Embodiment 1: as figure 1 , 2 As shown, a concrete tie-bar arch bridge suspender lower anchor connection structure, the concrete tie-bar arch bridge includes: tie beam 02 and arch rib 01, tie beam and arch rib are provided with several suspenders 03, the arch rib is arc-shaped, The two ends of the arch rib are integrated with the tie beam, and the suspender is vertically connected between the arch rib and the tie beam. It also includes lug connector 06, which includes pouring part 062 and connecting part 061. The pouring part is poured in the tie beam, the connecting part protrudes above the tie beam, and the bottom of the suspender is hinged and fixed to the connecting part. Such as image 3 , 4 As shown, the pouring part has a rectangular plate-like structure, and the end of the pouring part far away from the connection part is provided with a transverse restraint plate 063 perpendicular to the pouring part, and the upper end of the pouring part is provided with a ...

Embodiment 2

[0035] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 9 As shown, the fixing holes 081 are evenly and densely distributed on the positioning pipe, and the bolts 082 are connected to the internal threads of the fixing holes. When the positioning pipe and the tie beam are strengthened, when the positioning pipe is subjected to tension, the bolts can enhance the connection strength between the tie beam and the positioning pipe, avoiding the misalignment of the positioning pipe and thus avoiding the dislocation of the pouring part.

Embodiment 3

[0036] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1 or Embodiment 2, the difference is that, as Figure 10 As shown, the spiral pipe 083 is pierced in the positioning pipe, and when the positioning pipe is filled with concrete, the spiral pipe and the positioning pipe are poured integrally, and the spiral pipe can enhance the connection strength between the positioning pipe and the tie beam pouring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com