Gas cushion sealing bolts for gas insulated switchgear

A gas-insulated switch and equipment technology, which is applied in the setting of switchgear, switchgear, mechanical equipment, etc., can solve the problems of low rust and anti-corrosion technology, loose and aggravated glass glue, and prevent rust, aging and gas. Penetration, reduce the corrosion of iron structure, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

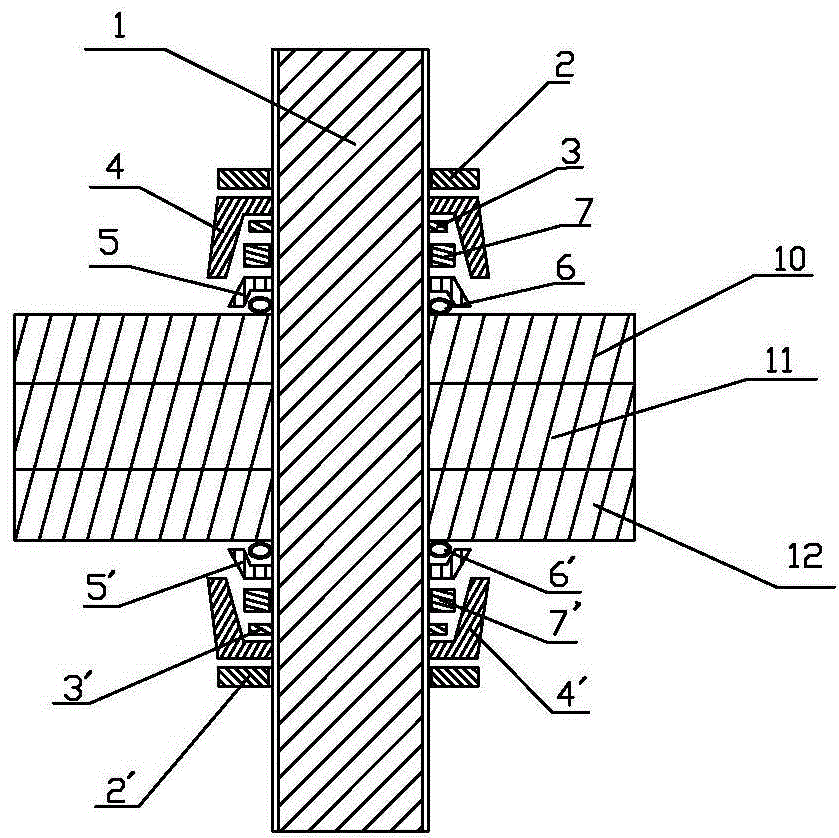

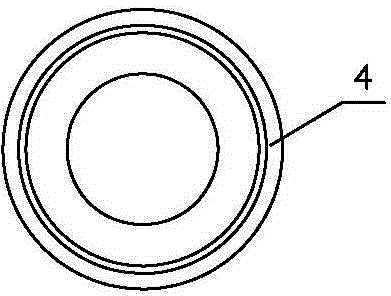

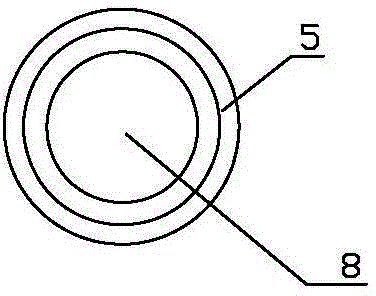

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 Make the invention. The gas-insulated switchgear uses an air cushion to seal the bolt, including the bolt body 1, the upper first layer of nut 2, the upper elastic washer 3, the lower end of the first layer of nut 2', the lower end of the elastic washer 3', the upper end of the first layer of nut 2 Rotate on the upper end of the bolt body 1, the upper elastic washer 3 is set on the bolt body 1 inside the upper first layer nut 2; the lower end first layer nut 2' rotates on the lower end of the bolt body 1, and the lower elastic washer 3' is set On the bolt body 1 inside the first layer of nuts 2' at the lower end; the middle part is a fastened upper flange 10, an insulating basin 11 and a lower flange 12, which is characterized in that: the first layer of nuts at the upper end The bolt body 1 between 2 and the elastic washer 3 at the upper end is provided with the first layer of insulating open basin-shaped button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com