A kind of flotation depressant and preparation method and application thereof

An inhibitor and flotation technology, applied in flotation, solid separation, etc., can solve the problems of low effective recovery rate, difficult separation of barite gangue minerals, poor quality of flotation concentrate, etc., and achieve low environmental pollution, Improve the comprehensive utilization level of resources, improve the effect of grade and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add deionized water:starch:ferric chloride with a mass ratio of 20:1:0.05 into the three-necked flask, and then put the three-necked flask into a magnetic stirrer for heating and stirring reaction in a water bath. The reaction temperature in the water bath is 90°C, and the stirring speed 800r / min, stirring until the solution turns reddish brown, and the obtained iron starch solution is used for flotation test research. The flotation test was carried out with XFGⅡ type hanging tank flotation machine. First, add 2g of pure minerals to the flotation tank, then add 35ml of distilled water, adjust the slurry for 1min, adjust the pH of the slurry to 9 with HCl or NaOH and stir for 2min, then add starch in turn Inhibitor 20mg / L stirred for 3min, sodium oleate 40mg / L stirred for 3min, and then scraped for 4min. After the flotation test, the foam product is filtered, dried, weighed, assayed and the recovery rate calculated.

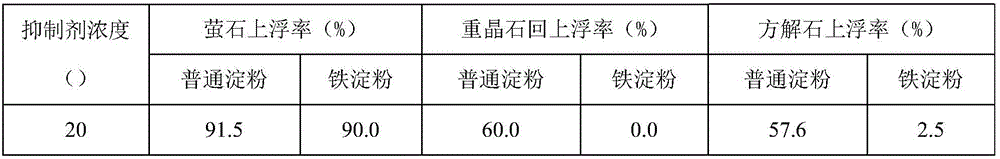

[0019] The inhibitory effects of iron starch and ord...

Embodiment 2

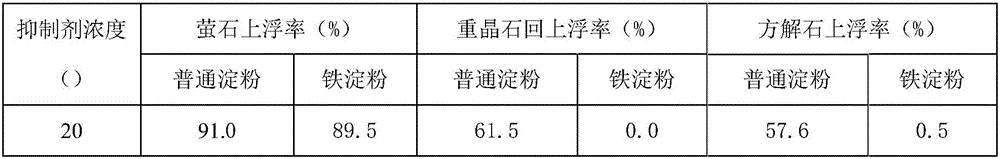

[0023] Add deionized water:starch:ferric chloride with a mass ratio of 100:1:0.2 into the three-necked flask, and then put the three-necked flask into a magnetic stirrer for heating and stirring reaction in a water bath. The reaction temperature of the water bath is 95°C, and the stirring speed 400r / min, stirring until the solution turns reddish brown, and the obtained iron starch solution is used for flotation test research. The flotation test was carried out with XFGⅡ type hanging tank flotation machine. First, add 2g of pure minerals to the flotation tank, then add 35ml of distilled water, adjust the slurry for 1min, adjust the pH of the slurry to 9 with HCl or NaOH and stir for 2min, then add starch in turn 20 mg / L of class inhibitors, stirred for 3 minutes, sodium oleate 40 mg / L, stirred for 3 minutes, and then scraped and soaked for 4 minutes. After the flotation test, the foam product is filtered, dried, weighed, assayed and the recovery rate calculated. Example test r...

Embodiment 3

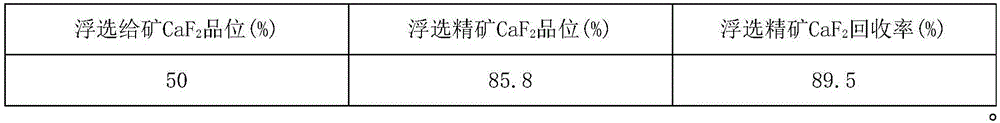

[0027] Add deionized water:starch:ferric chloride with a mass ratio of 100:1:0.2 into the three-necked flask, and then put the three-necked flask into a magnetic stirrer for heating and stirring reaction in a water bath. The reaction temperature of the water bath is 95°C, and the stirring speed 400r / min, stirring until the solution turns reddish brown, and the obtained iron starch solution is used for flotation test research. The flotation test was carried out with XFGⅡ hanging tank flotation machine. First, 1g of fluorite and 1g of barite were added to the flotation tank, then 35ml of distilled water was added, and the pulp was mixed for 1min. The pH of the slurry was adjusted to 6 with HCl or NaOH and stirred for 2min. Then add iron starch inhibitor 40mg / L and stir for 3 minutes, sodium oleate 40mg / L and stir for 3 minutes, then scrape and soak for 4 minutes, artificially mixed ore is separated by flotation once. After the flotation test, the foam product is filtered, dried,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com