Application of hydroxypropyl starch ether in scheelite flotation

A technology of hydroxypropyl starch ether and scheelite, applied in flotation, solid separation, etc., can solve the problems of poor quality of flotation concentrate, difficult separation of gangue minerals, low effective recovery rate, etc., and achieve low environmental pollution , improve the level of comprehensive utilization of resources, the effect of easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

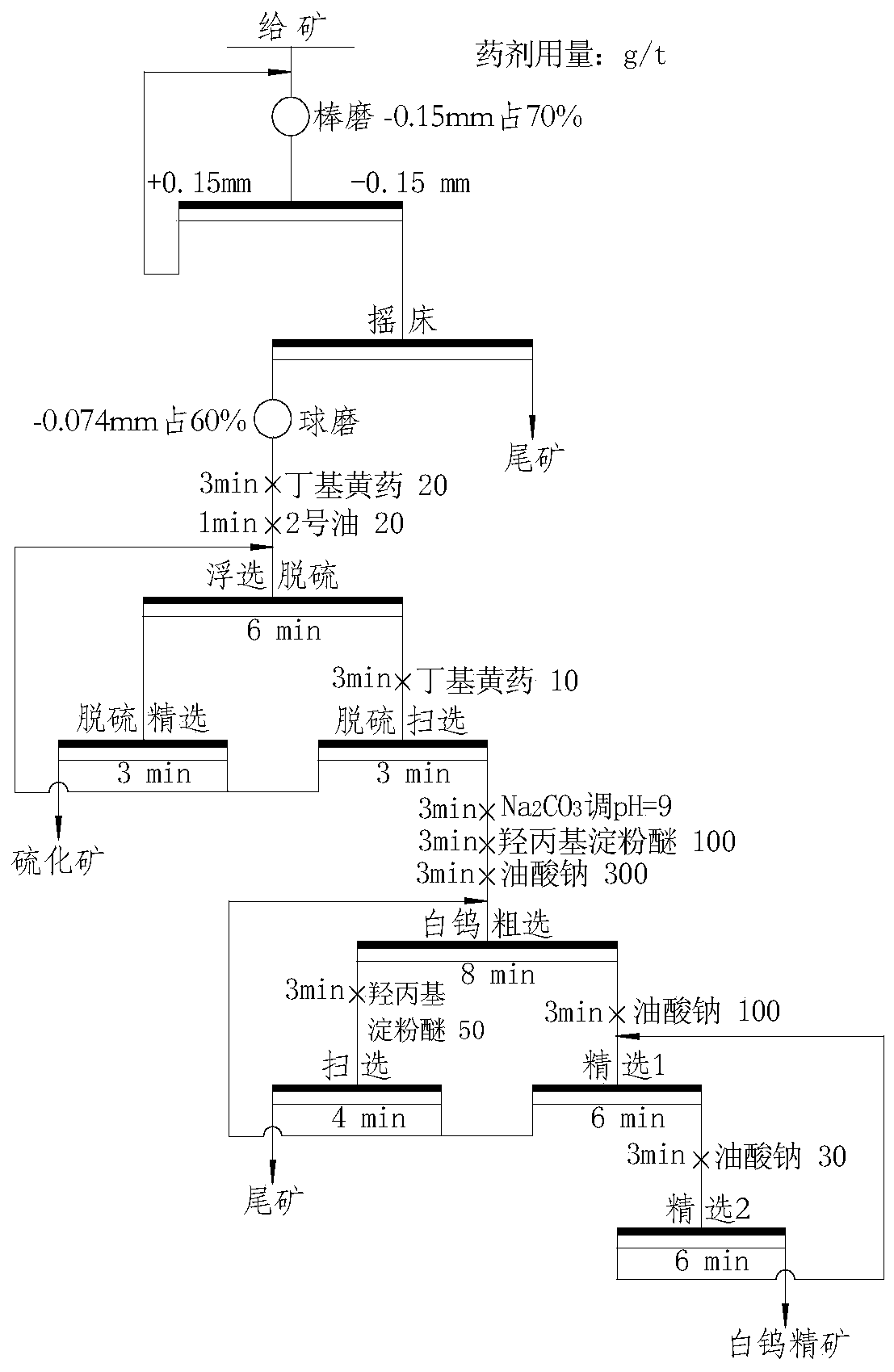

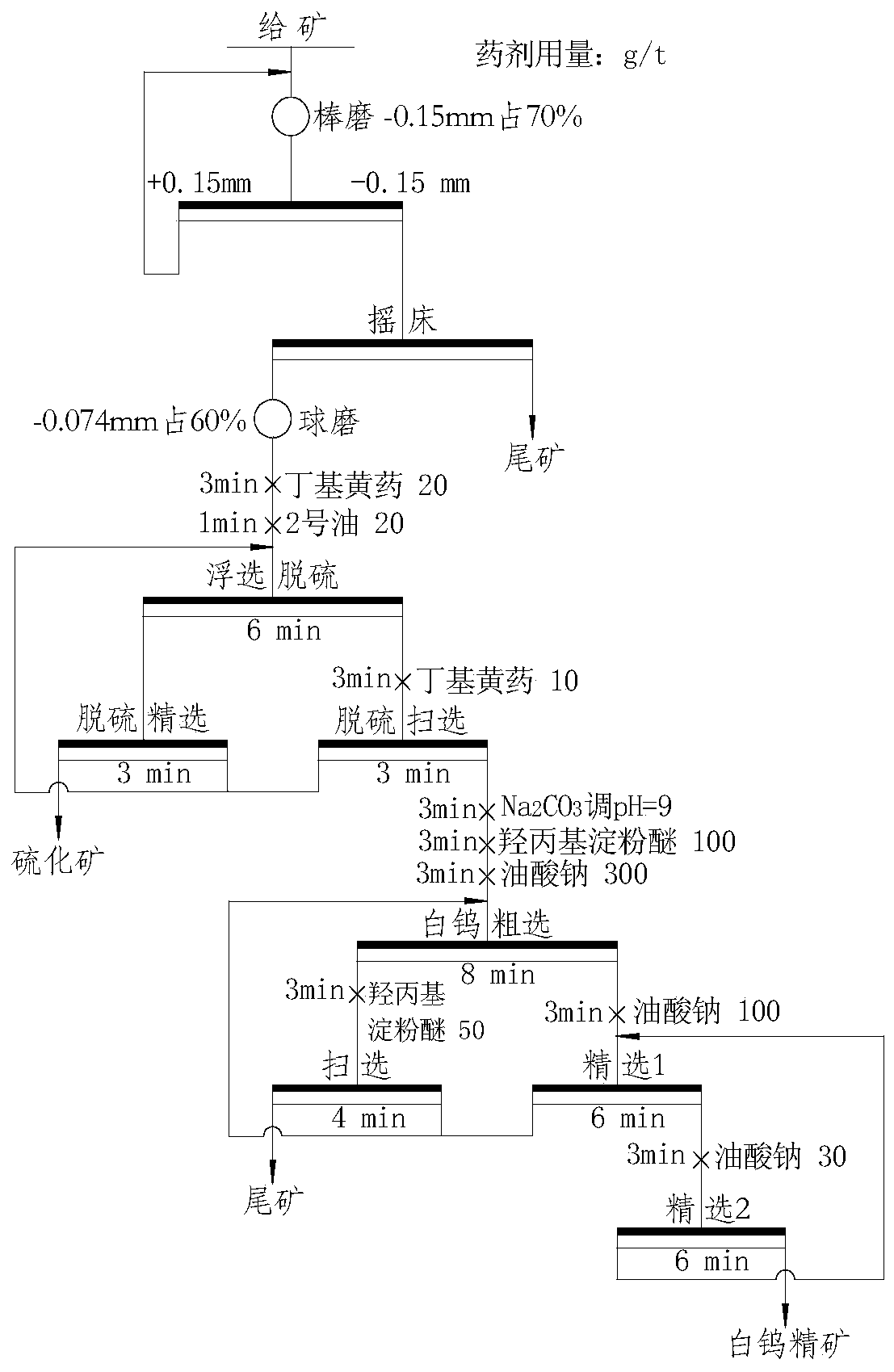

Method used

Image

Examples

Embodiment 1

[0025] The flotation test was carried out with XFGⅡ type hanging tank flotation machine. First, 2g of pure minerals were added to the flotation tank, and then 35ml of distilled water was added, and the pulp was adjusted for 1min. The hydroxypropyl starch ether inhibitor was stirred for 3 minutes, the sodium oleate 60mg / L was stirred for 3 minutes, and then scraped for 4 minutes. After the flotation test, the foam product is filtered, dried, weighed, assayed and the recovery rate calculated.

[0026] Examples The test results are shown in Table 1.

[0027] Table 1 Hydroxypropyl starch ether dosage on mineral inhibition behavior test results 1 (pH=7)

[0028]

Embodiment 2

[0030] The flotation test was carried out with XFGⅡ type hanging tank flotation machine. Firstly, 2g of pure minerals were added to the flotation tank, then 35ml of distilled water was added, and the slurry was adjusted for 1min. Propyl starch ether inhibitor was stirred for 3 minutes, sodium oleate 60 mg / L was stirred for 3 minutes, and then scraped for 4 minutes. After the flotation test, the foam product is filtered, dried, weighed, assayed and the recovery rate calculated.

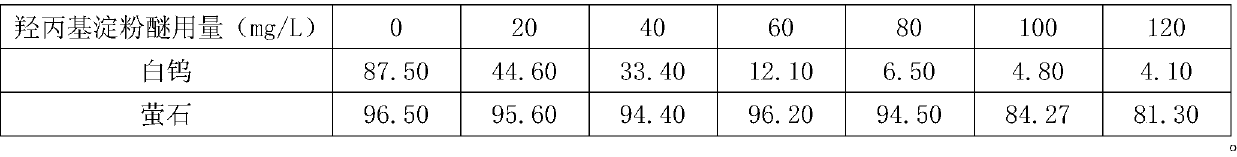

[0031] Example test results are shown in Table 2.

[0032] Table 2 Hydroxypropyl Starch Ether Inhibitory Behavior Experiment Result 2 (pH=9) to Minerals

[0033]

Embodiment 3

[0035] The flotation test was carried out with XFGⅡ type hanging tank flotation machine. First, 2g of pure minerals were added to the flotation tank, and then 35ml of distilled water was added, and the slurry was adjusted for 1min. The hydroxypropyl starch ether inhibitor was stirred for 3 minutes, the sodium oleate 60mg / L was stirred for 3 minutes, and then scraped for 4 minutes. After the flotation test, the foam product is filtered, dried, weighed, assayed and the recovery rate calculated.

[0036] Example test results are shown in table 3.

[0037] Table 3 Hydroxypropyl Starch Ether Inhibitory Behavior Experimental Results 3 (pH=12) to Minerals

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com