Airbag-like grinding head for polishing extra-large-deviation-degree aspheric surface

An aspheric surface and deviation degree technology, applied in the field of aspheric advanced optical manufacturing, can solve the problems such as the inability to effectively correct the intermediate frequency error, the mismatch of the curvature radius, and the inability to effectively remove the intermediate frequency error, and achieve the effect of enhancing the simplicity and improving the polishing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

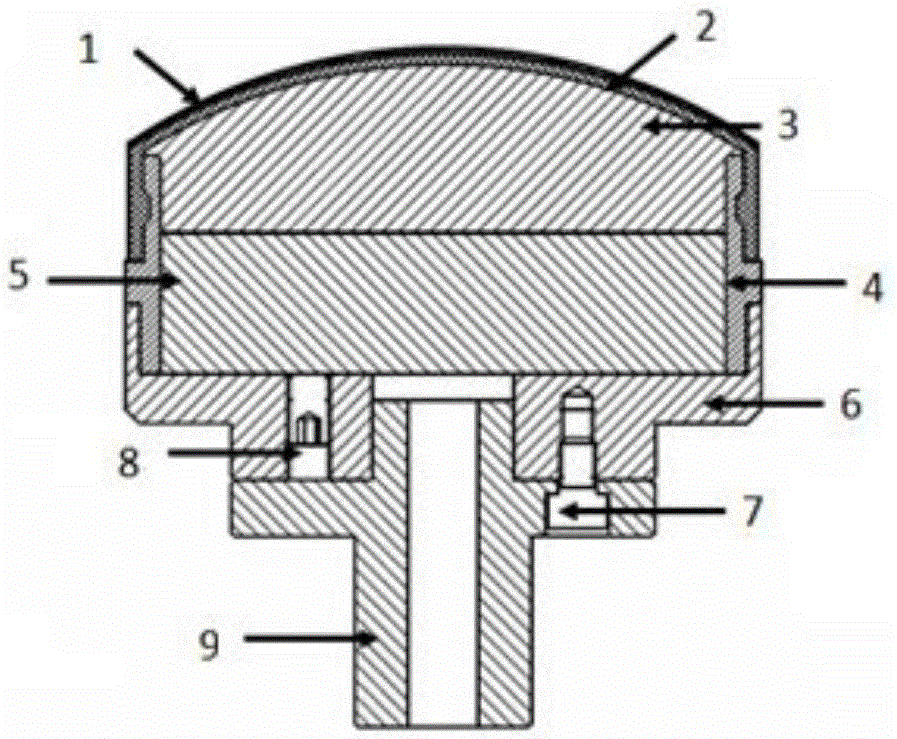

[0017] Specific implementation mode 1. Combination Figure 3 to Figure 5 To illustrate this embodiment, the airbag-like grinding head for polishing super-large deviation aspheric surfaces includes a polishing mold 1, a polishing airbag cap 2, an elastic material 3, an airbag skeleton 4, a height adjustment plate 5, a grinding head base 6, and fastening bolts 7 , top wire 8 and connecting flange 9;

[0018] The polishing mold 1 is glued to the surface 2 of the polishing airbag; the elastic material 3 is a special material, which is sealed in the airtight structure composed of the polishing airbag cap 2, the airbag skeleton 4 and the height adjustment plate 5; the polishing airbag The cap 2 is tightly connected with the trapezoidal depression on the outer wall of the airbag frame 4 through a circle of trapezoidal protrusions on the inner wall; the height adjustment plate 5 adjusts its height through an inner hexagonal screw; the grinding head base 6 and the airbag frame 4 pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com