A door panel drawing device

A wire drawing and door panel technology, which is applied in the direction of grinding skateboards, grinding machines, grinding/polishing equipment, etc., can solve the problems of wire drawing direction, uneven depth, dust damage to workers' physical and mental health, and different drawing texture effects. Achieve the effect of novel and unique structure composition, high degree of automation, stable direction and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with accompanying drawing, the present invention is described in detail:

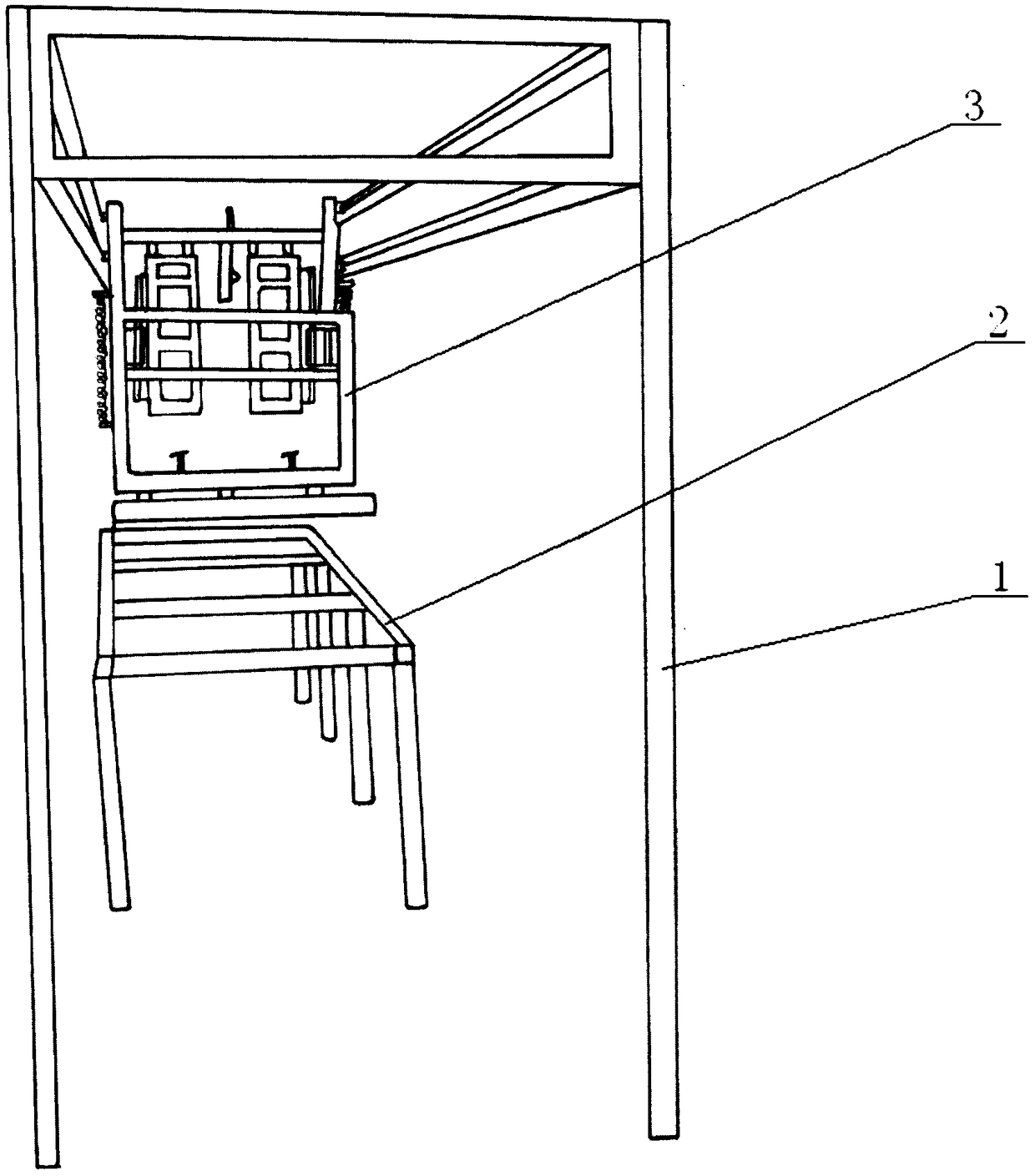

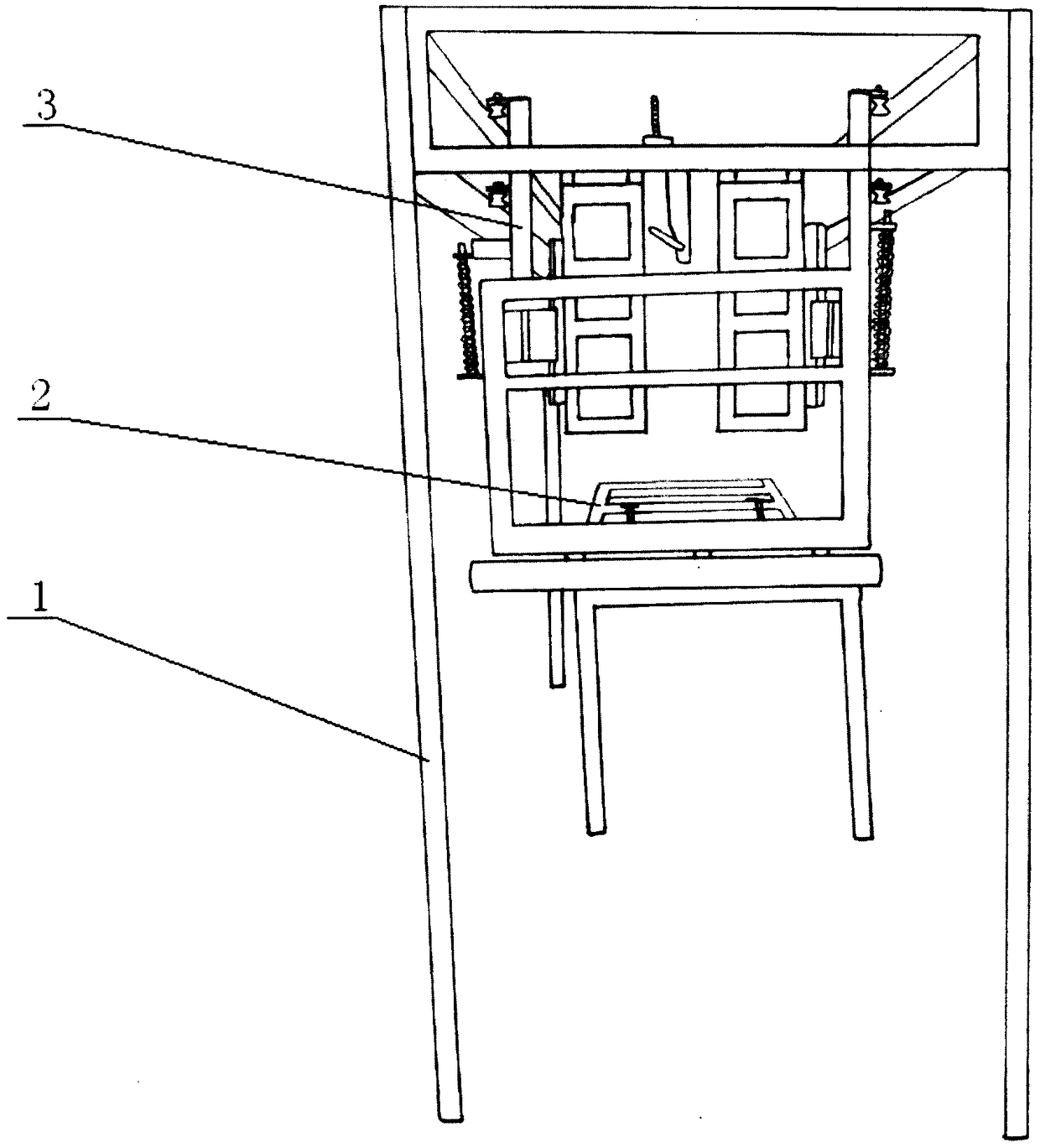

[0027] The invention is composed of a frame body (1), a door panel placement frame (2), and a drawing movable frame (3).

[0028] figure 1 and figure 2 Shown is the structural representation of the present invention. Wherein, 1 is a frame body, 2 is a door panel placement frame, and 3 is a drawing movable frame.

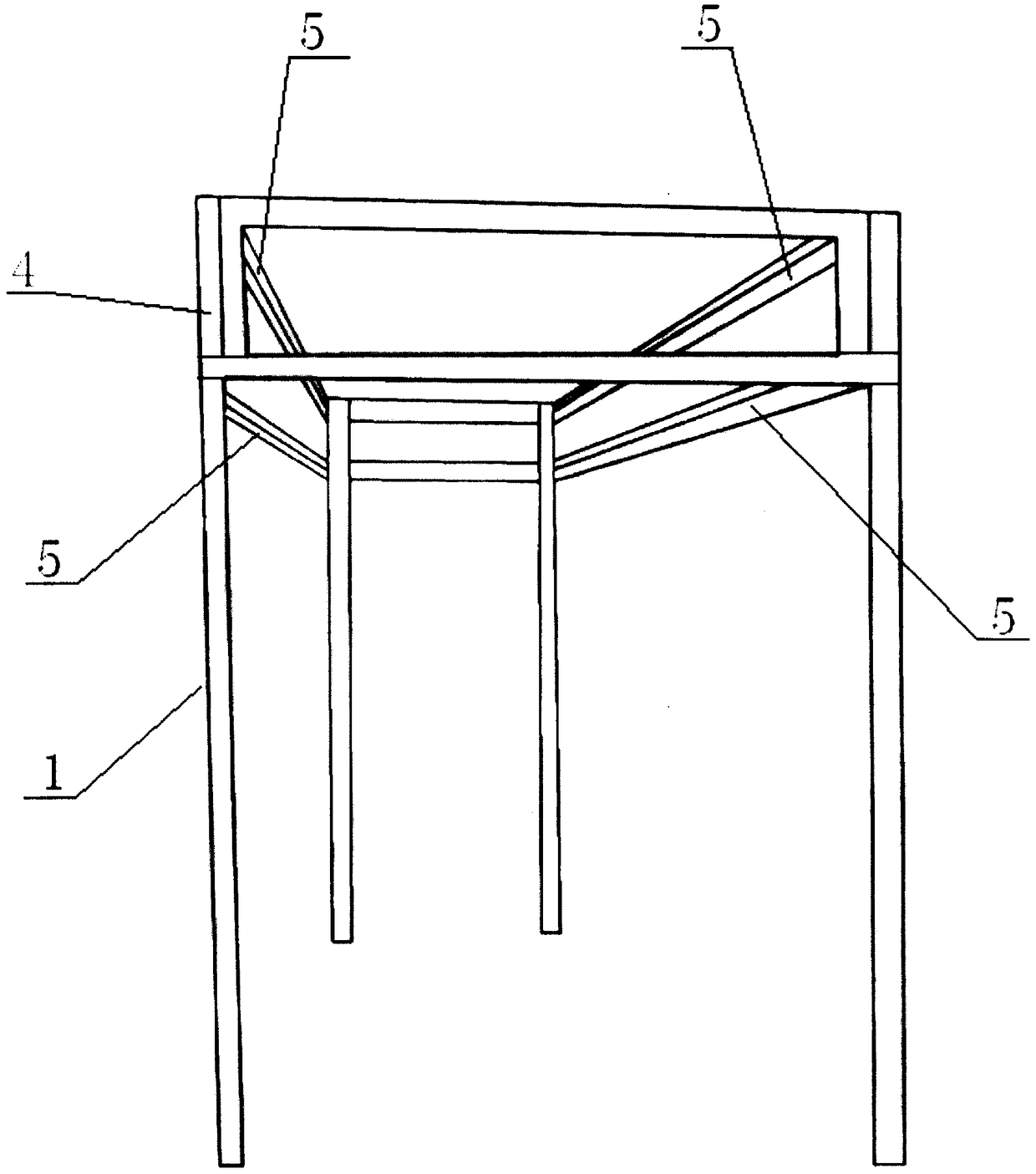

[0029] image 3 Shown is a schematic structural view of the frame (1) in the present invention. The support body (1) is a square three-dimensional frame, and a guide rail frame (4) is provided on the top of the support body (1), and two guide rails one (5) are all provided with on the left and right sides of the guide rail frame (4).

[0030] Figure 4 Shown is the structural representation of the door panel installation frame (2) in the present invention. Door panel placement frame (2) is a square three-dimensional frame.

[0031] Figure 5 Shown is the sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com