Method of estimating brake pad wear and vehicle having a controller that implements the method

A technology of brake pads and brake rotors, applied in the direction of brake types, vehicle components, brake safety systems, etc., which can solve the problems of inconvenient inspection of brake pads and prolonged parking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

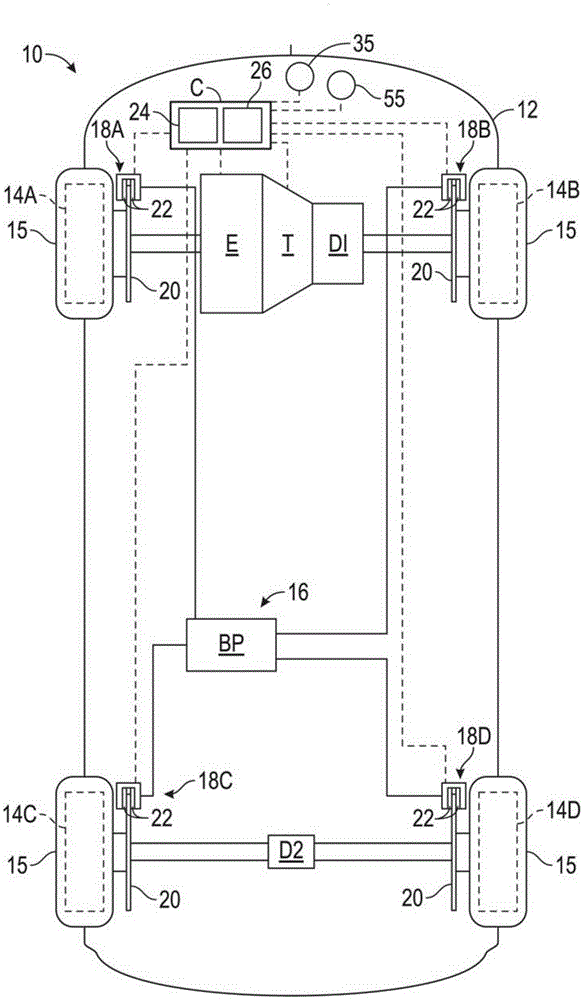

[0065] Referring to the drawings, wherein like reference numerals refer to like parts throughout, figure 1 Vehicle 10 is shown which may have a body 12 operably connected to rotatable wheels 14A, 14B, 14C, 14D for moving body 12 when the vehicle is propelled by engine E via transmission T. In one non-limiting example, vehicle 10 is a front wheel drive vehicle. As is known, differential case D1 is operatively connected to the front wheels 14A, 14B, while differential case D2 is operatively connected to the rear wheels 14C, 14D via half shafts. Tires 15 are shown mounted on wheels 14A, 14B, 14C, 14D. The vehicle 10 includes a braking system 16 configured to stop rotation of the wheels 14A, 14B, 14C, 14D. The braking system 16 includes a fluid pressure source BP in communication with a corresponding braking mechanism 18A, 18B, 18C, 18D operatively connected to each corresponding wheel 14A, 14B, 14C, 14D. The brake mechanisms 18A, 18B, 18C, 18D each have a brake rotor 20 rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com