Automatic pneumatic dredging valve

A dredging valve, automatic technology, applied in the direction of conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of abnormal air supply, aging of exposed pipelines, high price, etc., to prevent easy aging or damage, air leakage, Inexpensive and fast-response effects to make and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

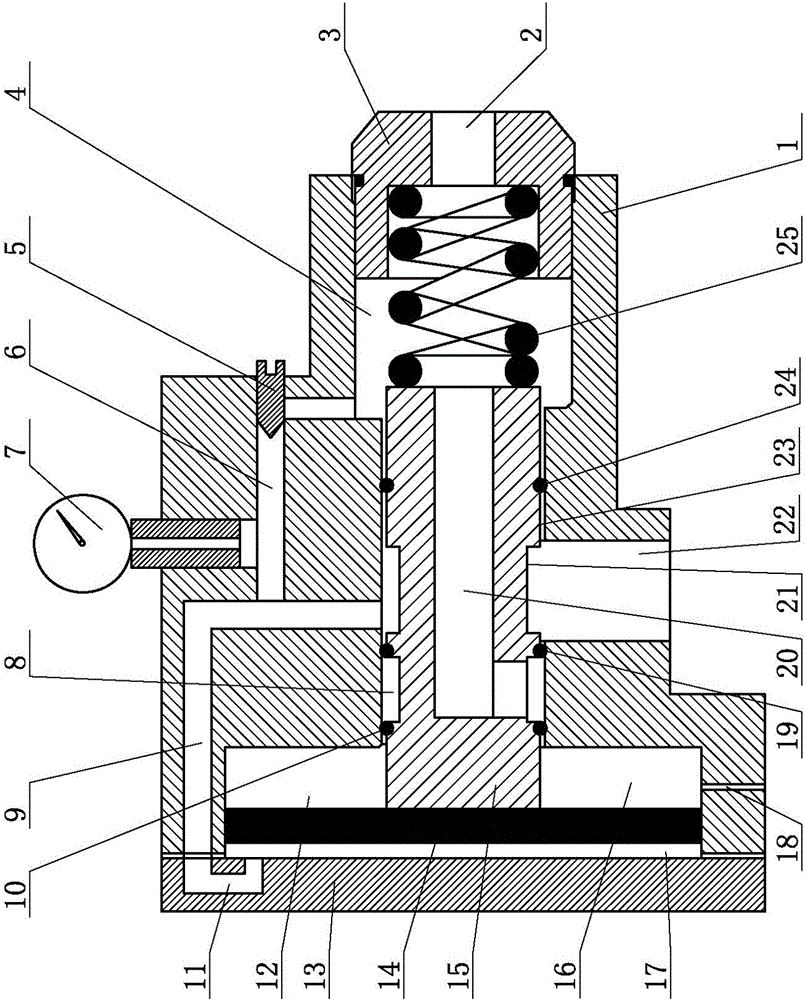

[0009] Such as figure 1 As shown, the pneumatic automatic dredging valve of the present invention includes a valve body 1, a spring chamber 4, a ejector rod chamber 23 and a valve chamber 12 are provided in the valve body 1, and the valve body 1 is provided with an end installation end of the valve chamber 12 Cover 13, valve body 1 is provided with spring chamber 4 at one end to install spring gland 3, ejector rod chamber 23 communicates with valve chamber 12 and spring chamber 4 respectively, valve disk 14 is installed in valve chamber 12, valve disk 14 will valve The film cavity 12 is divided into two independent first chambers 16 and second chambers 17. The ejector rod 15 is installed in the ejector rod chamber 23. There is a certain gap between the ejector rod 15 and the ejector rod chamber 23 so that the ejector rod 15 can move axially. And keep the second chamber 17 connected with the conveying system pipeline, spring 25 is installed in the spring cavity 4, the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com