Material tray feeding device and feeding method

A tray and platform technology, applied in the field of tray unloading device, can solve the problems of cumbersome tray unloading method, single unloading function, and difficulty in popularization and application, so as to save tray changing time, improve production efficiency, and avoid space area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

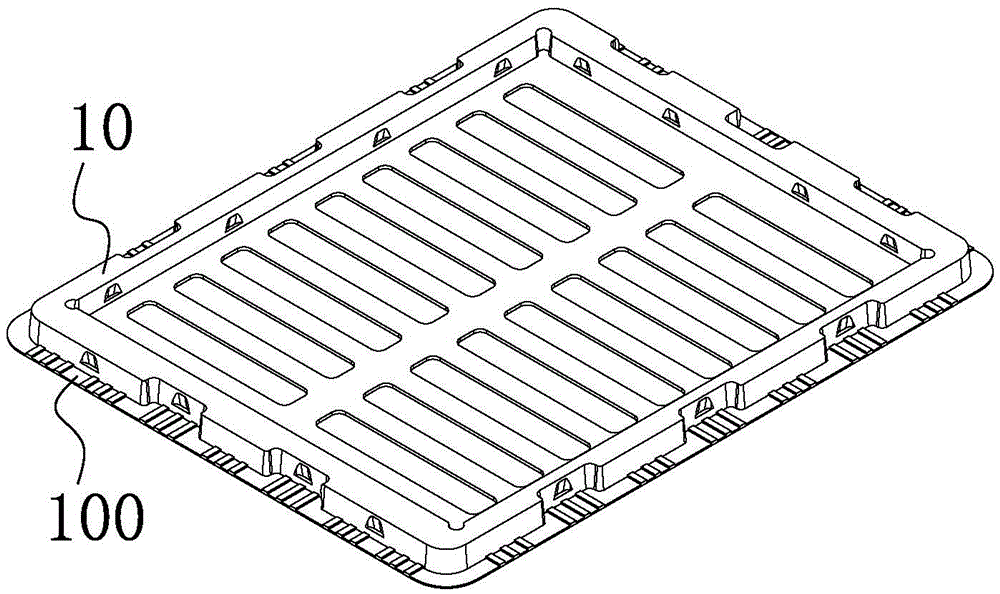

[0039] like figure 1 As shown, in the tray unloading device, each tray 10 has a skirt 100 in the bottom circumferential direction and an annular space is formed between the skirts 100 of two adjacent trays 10. This structure is convenient for subsequent sub-discs one by one.

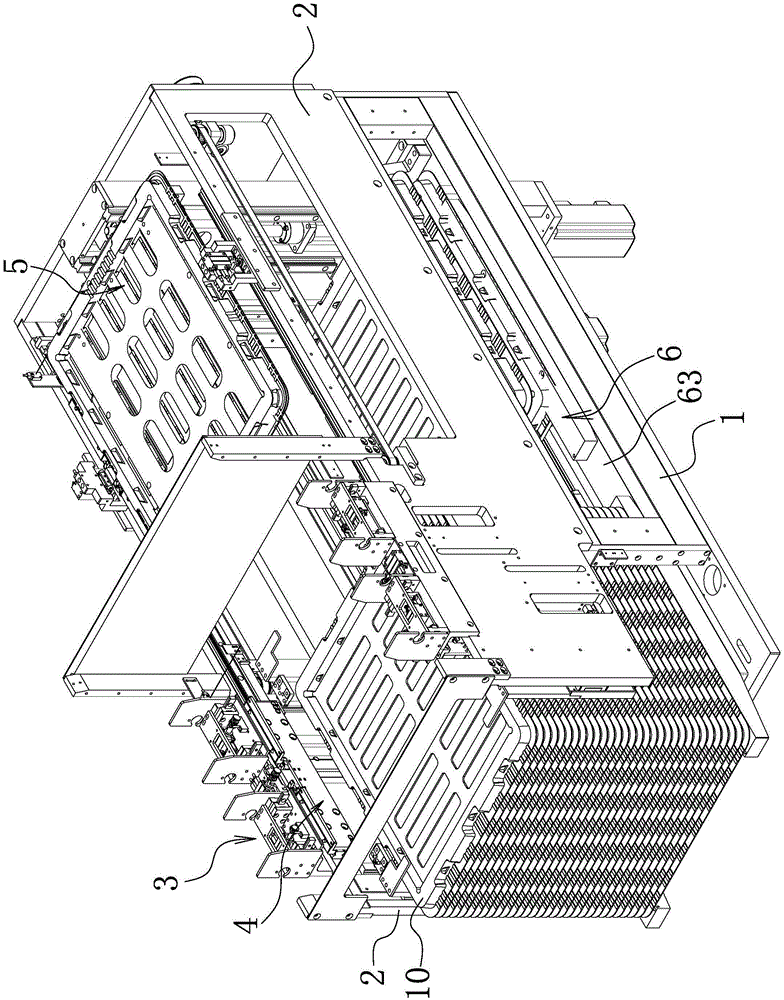

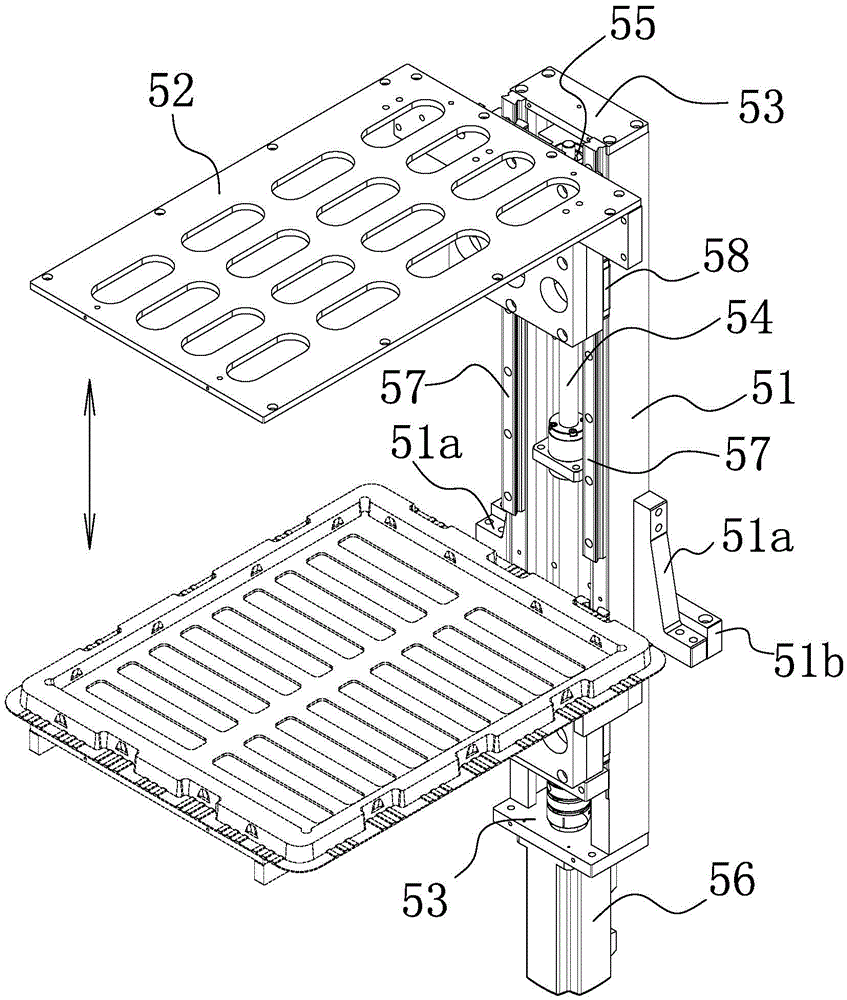

[0040] like figure 2As shown, the device includes a base plate 1, which is provided with a number of mounting holes for subsequent installation and positioning. Side support plates 2 are respectively provided on both sides of the base plate 1 and the side support plates 2 are symmetrically distributed. One end corresponding to the side support plate 2 is provided with a tray separating mechanism 3 that can separate the stacked trays 10 one by one from bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com