Fluorescent carbon dot narrow in full width at half maximum and preparation method and application thereof

A technology of fluorescent carbon dots and full width at half maximum is applied in the field of preparation of narrow half width fluorescent carbon dots, which can solve the problems of expensive raw materials, low output, complicated processes and the like, and achieve the effect of improving resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1 Measure 100ml of distilled water as the electrolyte.

[0033] 2 Two high-purity graphite rods (10 cm in length and 0.5 cm in diameter) were ultrasonically cleaned in alcohol and distilled water for 30 minutes. The cleaned graphite rod is vertically inserted into the electrolyte solution described in step 1, with a fixed distance of 2 cm.

[0034] 3 Use a DC stabilized power supply for power supply, and a voltage of 60V is applied to the electrodes described in step 2.

[0035] 4. Filter the obtained dark brown liquid, then centrifuge at 10,000 r / min for 10 min to remove large particles visible to the naked eye to obtain an aqueous solution containing carbon dots.

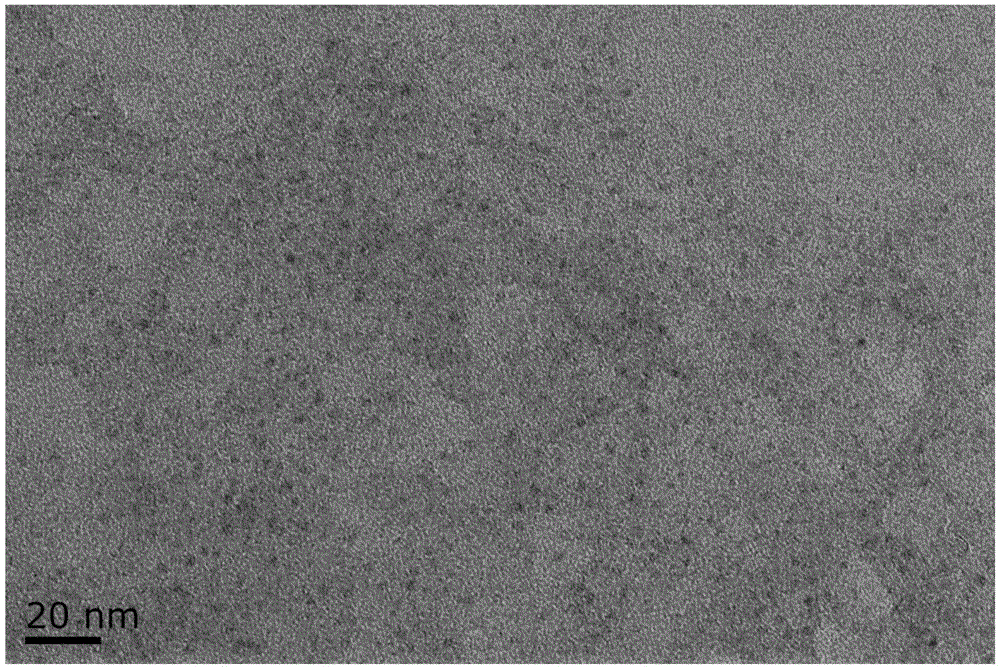

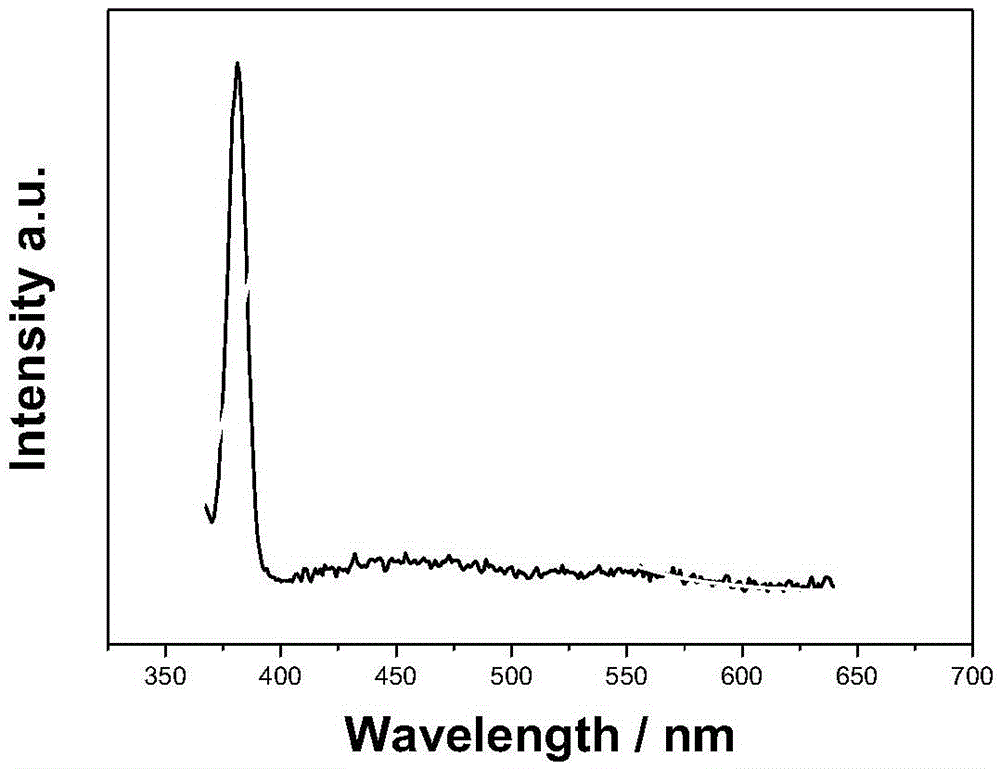

[0036] 5 Characterization of carbon dots: use a fluorescence spectrophotometer to obtain photoluminescence (PL) spectra at different excitation wavelengths (320-440nm, step size 20nm); drop the carbon dot solution on a copper grid with a carbon support film, bake Dry-take TEM images such as figure 1 show...

Embodiment 2

[0038] 1 Measure 100ml of distilled water as the electrolyte.

[0039]2 Two high-purity graphite rods (10 cm in length and 0.5 cm in diameter) were ultrasonically cleaned in alcohol and distilled water for 30 minutes. The cleaned graphite rod is vertically inserted into the electrolyte solution described in step 1, with a fixed distance of 2 cm.

[0040] 3 Use a three-electrode system, place the reference electrode between the working electrode and the counter electrode, record the changes in electrical parameters, and study the impact of changes in electrical parameters on the product.

[0041] 4 Use a DC stabilized power supply for power supply, and apply a voltage of 60V to the electrodes described in step 2.

[0042] 5. Filter the obtained dark brown liquid, and then centrifuge at 10,000 rpm for 10 min to remove large particles visible to the naked eye to obtain an aqueous solution containing carbon dots.

[0043] 6 Characterization of carbon dots: use a fluorescence spe...

Embodiment 3

[0045] 1 Measure 100ml of distilled water as the electrolyte.

[0046] 2 A high-purity graphite rod (10 cm long, 0.5 cm in diameter), ultrasonically cleaned in alcohol and distilled water for 30 minutes. Use a platinum wire as the counter electrode, and insert the cleaned graphite rod as the working electrode vertically into the electrolyte solution described in step 1, with a fixed distance of 2 cm.

[0047] 3 Use a DC stabilized power supply for power supply, and a voltage of 60V is applied to the electrodes described in step 2.

[0048] 4. Filter the obtained dark brown liquid, and then centrifuge at 10,000 rpm for 10 min to remove large particles visible to the naked eye to obtain an aqueous solution containing carbon dots.

[0049] 5 Characterization of carbon dots: use a fluorescence spectrophotometer to obtain photoluminescence (PL) spectra at different excitation wavelengths (340-440nm, step size 20nm); drop the carbon dot solution on a copper grid with a carbon suppo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap