A kind of mg-ag-al ternary hydrogen storage alloy and its preparation method

A hydrogen storage alloy and alloy technology, applied in the field of hydrogen storage technology and materials, can solve the problems that are not conducive to improving the thermodynamic properties of magnesium hydride, the preparation of multi-element magnesium-based hydrogen storage alloys, and the large difference in the melting point of alloy elements, so as to save the preparation cost , Dehydrogenation thermodynamic performance improvement, the effect of easy alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the Mg-Ag-Al ternary hydrogen storage alloy of the present invention comprises the following steps:

[0035] (1) Take Mg powder and Ag powder by alloy composition, configure sample A;

[0036] (2) The obtained sample A is mixed on a ball mill;

[0037] (3) Sintering the mixed powder obtained in step (2) in a vacuum tube furnace with argon protection to obtain sample B;

[0038] (4) take by weighing the sample B that Al powder and step (3) obtain by alloy composition, configure sample C;

[0039] (5) Finally, the uniformly mixed sample C was ball-milled under an argon atmosphere to obtain a Mg-Ag-Al ternary alloy.

[0040] The protection air pressure of sintering in the step (3) of the present invention is 250~350Pa, and the sintering temperature is 550~650 ℃, and the sintering time is 16~24h; In the step (5), the protection pressure of ball milling is 0.80~1.30 atmospheric pressure, and the ball mill rotating speed is 240~360rpm, ball powder...

Embodiment 1

[0044] Mg powder with a purity of 99.8% and Ag powder with a purity of 99.9% are mixed according to a molar ratio of 80:15, mixed on a planetary ball mill, and the obtained mixed powder is placed in a crucible and placed in a vacuum tube furnace to pass Argon protection sintering for 20 hours, the sintering temperature is 600°C, and the protection pressure is 300Pa; then the Al powder with a purity of 99.95% and the powder obtained by sintering are mixed according to the molar ratio of 95:5, and then the above mixed powder is mixed under an argon atmosphere Ball milling, the ball milling time is 20h, the ball powder mass ratio is 20:1, the rotating speed is 300rpm, and the protection pressure is 1 atmosphere; the final composition is Mg 80 Ag 15 al 5 Ternary hydrogen storage alloy.

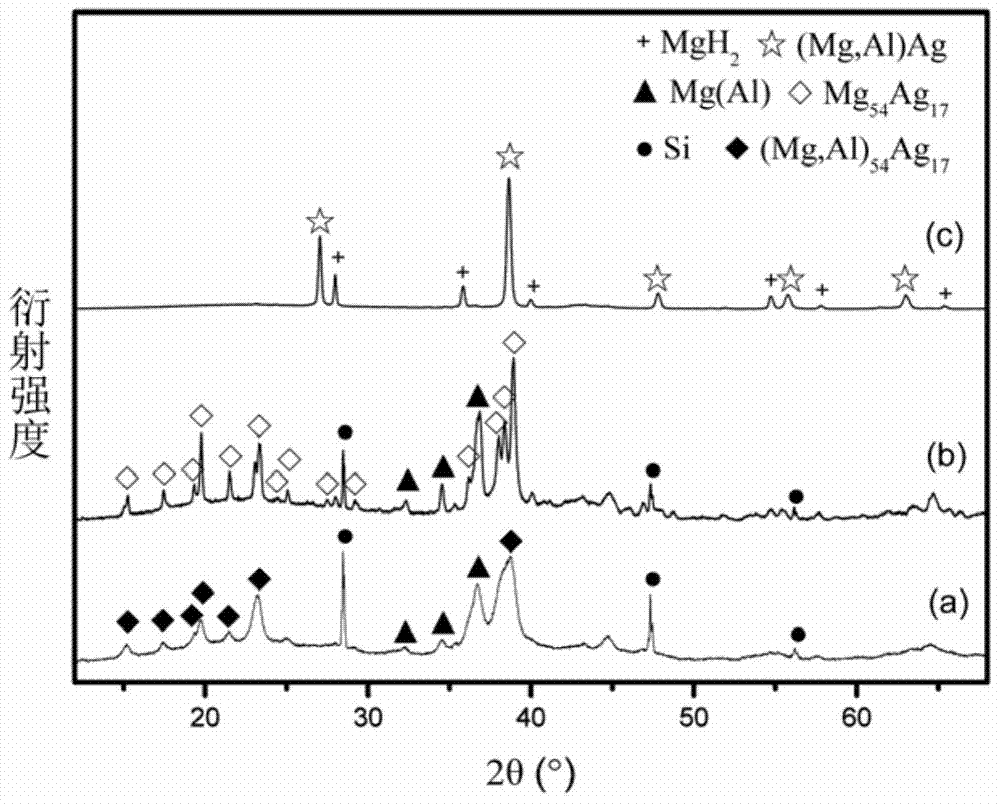

[0045] The phase composition of the alloy after ball milling is Mg(Al) solid solution and (Mg,Al) 54 Ag 17 Solid solution, after hydrogenation to form MgH 2 and (Mg,Al)Ag solid solution phase...

Embodiment 2

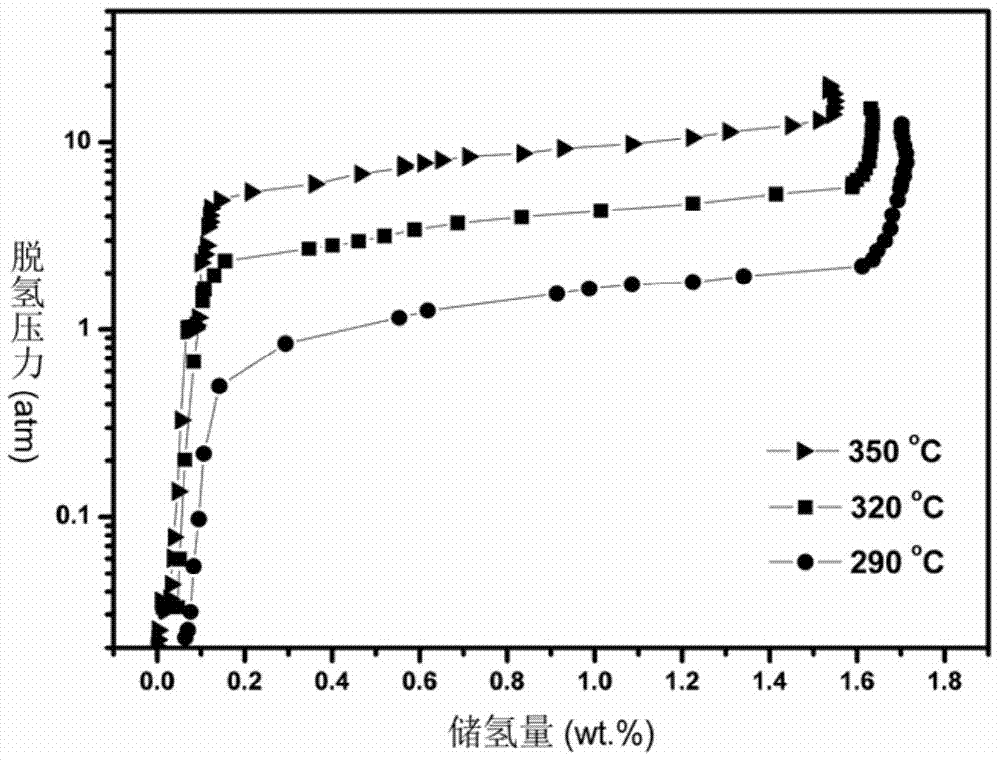

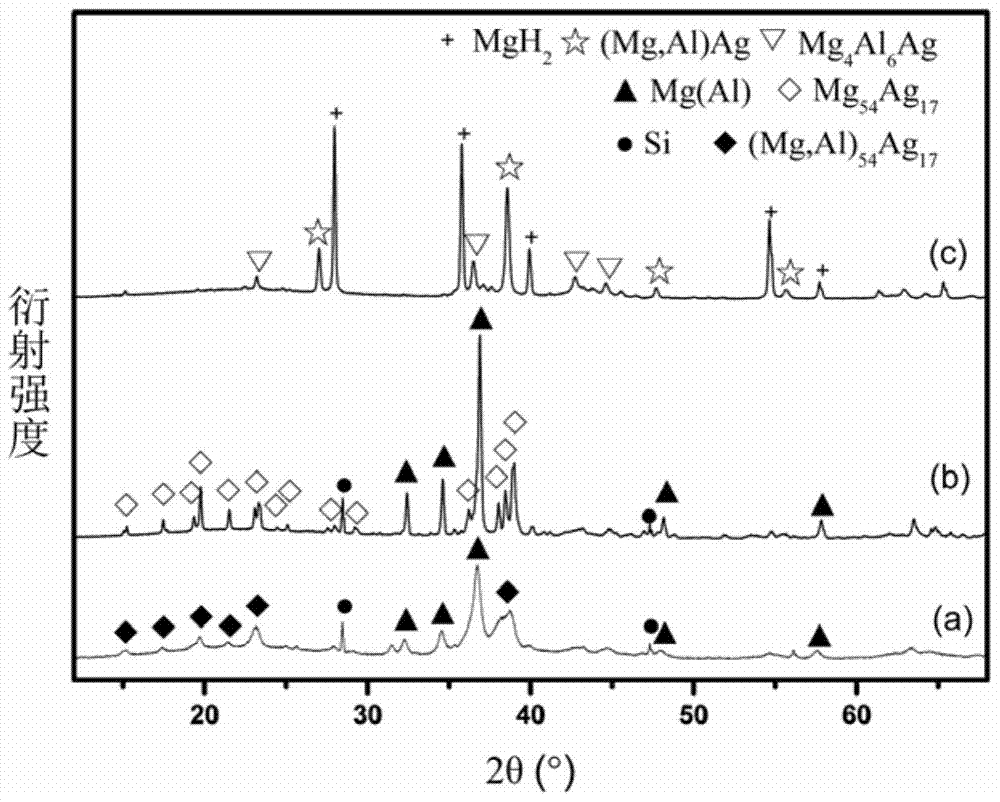

[0047] Mix the Mg powder with a purity of 99.8% and the Ag powder with a purity of 99.9% according to a molar ratio of 85:5, mix the powder on a planetary ball mill, put the obtained mixed powder in a crucible and place it in a vacuum tube furnace to pass Argon protection sintering for 20 hours, the sintering temperature is 550°C, and the protection pressure is 300Pa; then the Al powder with a purity of 99.95% and the sintered powder are mixed according to the molar ratio of 90:10, and then the above mixed powder is ball milled under an argon atmosphere , the ball milling time is 15h, the ball powder mass ratio is 20:1, the rotating speed is 300rpm, and the protection pressure is 1 atmosphere; the final composition is Mg 85 Ag 5 al 10 Ternary hydrogen storage alloy. Such as image 3 As shown, the phase composition of the alloy after ball milling is Mg(Al) solid solution and (Mg,Al) 54 Ag 17 Solid solution, after hydrogenation to form MgH 2 , (Mg,Al)Ag solid solution and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap