Upper tower layer structure of cleat-shaped direct-current linear tower

A technology of straight tower and layer structure, applied in the direction of towers, life-saving equipment, safety belts, etc., can solve the problems that the guide rails cannot be used for protection work, and the protection against falling can not be realized, so as to achieve the effect of ensuring the use performance and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

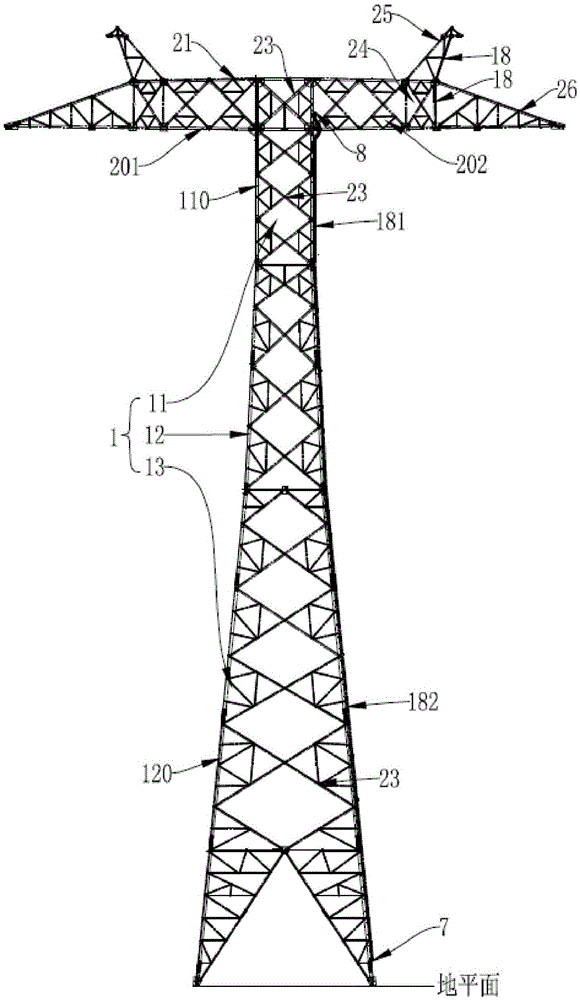

[0042] Such as figure 1 and figure 2 Shown, the upper tower layer structure of a kind of Yangjiao DC straight line tower, comprises tower body 1; The top of described tower body 1 is provided with upper tower layer, and described upper tower layer comprises left wing 201 and right wing 202, and described left wing 201 and The right wing 202 is symmetrically distributed on both sides of the tower body 1; the left wing 201 and the right wing 202 are installed symmetrically, which has a simple structure and improves the stability and wind resistance of the tower body 1.

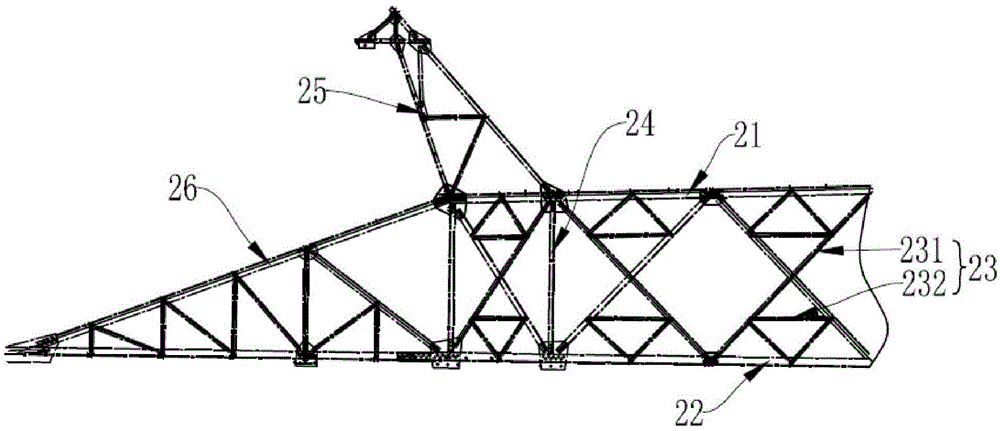

[0043] Described left wing 201 and right wing 202 all comprise upper cross bar 21, lower cross bar 22, support assembly 23, rectangular frame 24, upper wing 25 and lower wing 26 respectively; Fixed on the tower body 1, a number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com