Zero-pivot and large-corner crossed reed type flexible hinge

A technology of flexible hinges and large rotation angles, which is applied in the directions of pivot connections, joints, manipulators, etc., can solve problems that affect motion accuracy and cannot be overcome, and achieve the effect of improving rotation accuracy, reducing errors, and fewer structural components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

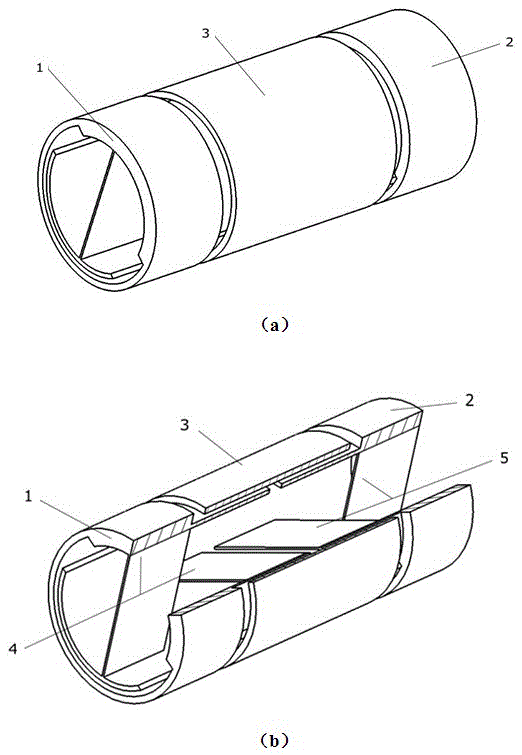

[0027] Such as figure 1 As shown, a zero-axis drift large-angle cross-reed type flexible hinge at least includes a left outer rotating part 1, a right outer rotating part 2, a rigid middle part 3, a left crossing reed 4 and a right crossing reed 5; The rotating part 1, the rigid middle part 3 and the right outer rotating part 2 are placed coaxially on the left, middle and right in sequence, and there is a certain gap between the left outer rotating part 1 and the right outer rotating part 2 and the rigid middle part 3 to ensure the rigid middle Part 3 does not contact and rub against the left outer rotating part 1 and right outer rotating part 2 during the movement process, and also allows the rigid middle part 3 to have a certain movement along the direction perpendicular to the rotation axis of the flexible hinge; the left cross reed 4 Place the right cross reed 5 in a collinear manner with the cross line, the reed arrangement of the right cross reed 5 and the left cross ree...

Embodiment 2

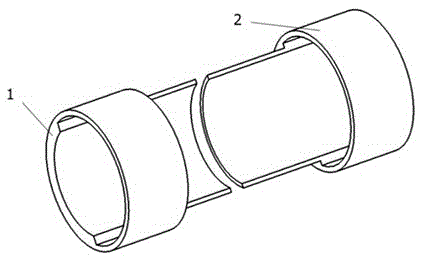

[0035] Such as Figure 6 As shown, a zero-axis drift large-angle cross-reed type flexible hinge at least includes a left outer rotating part 1, a right outer rotating part 2, a rigid middle part 3, a left crossing reed 4 and a right crossing reed 5; The rotating part 1 and the right outer rotating part 2 are placed on the left and right concentric axes in turn, and the rigid middle part 3 extends into the cavity of the left outer rotating part 1 and the right outer rotating part 2; the left outer rotating part 1 and the right outer rotating part 2 are connected with the rigid There is a certain gap between the middle parts 3 to ensure that the rigid middle part 3 does not touch and rub against the left outer rotating part 1 and the right outer rotating part 2 in the process of moving; the left outer rotating part 1 and the rigid middle part 3 pass through The left cross reed 4 is connected to form a left flexible hinge body, and the right outer rotating member 2 and the rigid ...

Embodiment 3

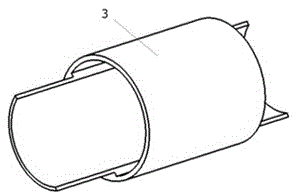

[0041] Such as Figure 10 As shown, a zero-axis drift large-angle cross-reed flexible hinge includes at least a left outer rotating member 1, a right outer rotating member 2, a rigid middle member 3, a left crossing reed 4 and a right crossing reed 5; Reed 4 and right cross reed 5 are placed by the collinear mode of intersection line, and the reed arrangement mode of right cross reed 5 and the reed arrangement mode of left cross reed 4 are symmetrical along the intersection line; The upper or lower end is connected to the left outer rotating part 1, and the lower or upper end is connected to the rigid middle part 3; the upper or lower end of the right cross reed 5 is connected to the right outer rotating part 2, and the lower or upper end is connected to the rigid middle part 3; the left outer rotating part 1 and The rigid middle piece 3 is connected by the left cross reed 4 to form a left flexible hinge body, and the right outer rotating piece 2 and the rigid middle piece 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com