Cover body with support frames

A support frame and cover technology, which is applied to fluid heaters, equipment for eliminating weeds, air heaters, etc., can solve problems such as turbulent flow at the air outlet, reduced efficiency of heating devices, and inability to perform precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

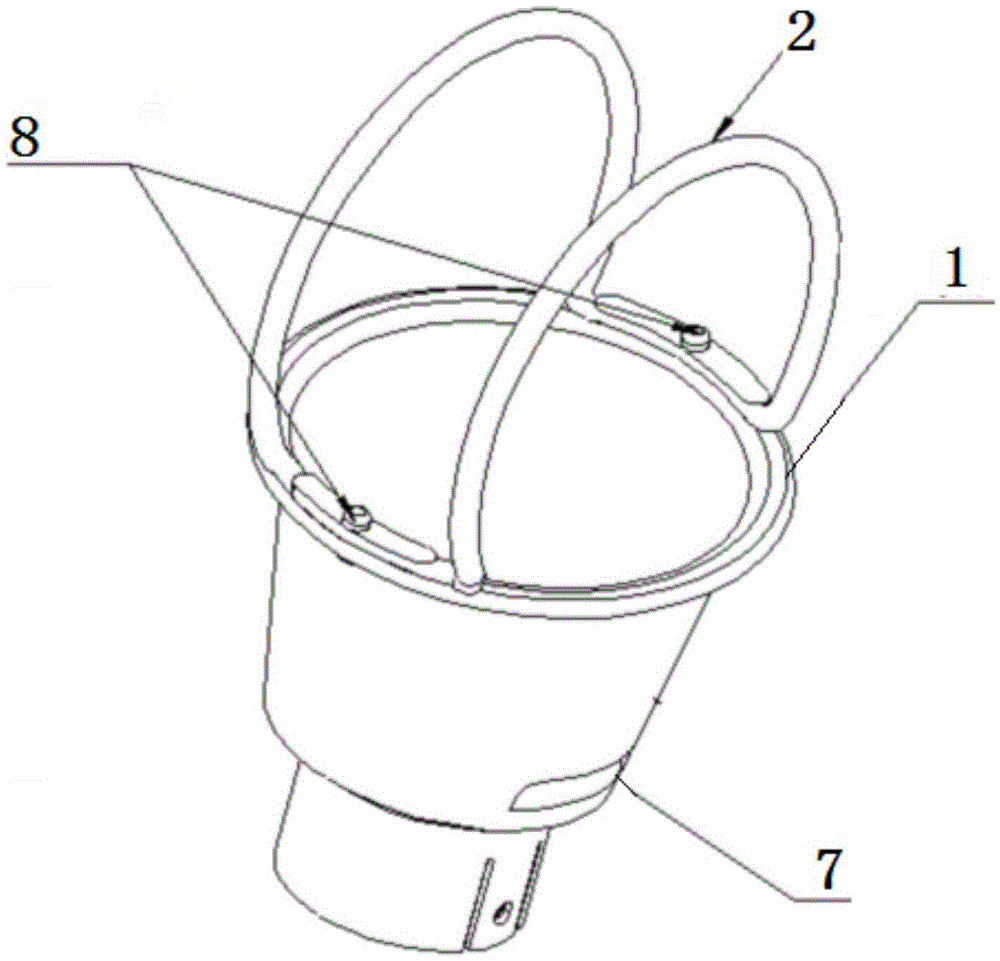

[0019] Such as figure 1 As shown, the cover body with the support frame is installed on the heat gun, and the free edge 1 of the cover body is fixed by rivets 8 at least two arc-shaped metal support rings 2 arranged in parallel as the support frame. The metal support ring 2 does not block the air outlet of the heat gun. Such a structure ensures a distance of at least 1 centimeter between the free edge 1 of the cover body and the processing object, and usually this distance is preferably 3 centimeters. During the heating process, the radian of the metal support ring 2 can also be used to adjust the heating angle relatively labor-saving and accurately.

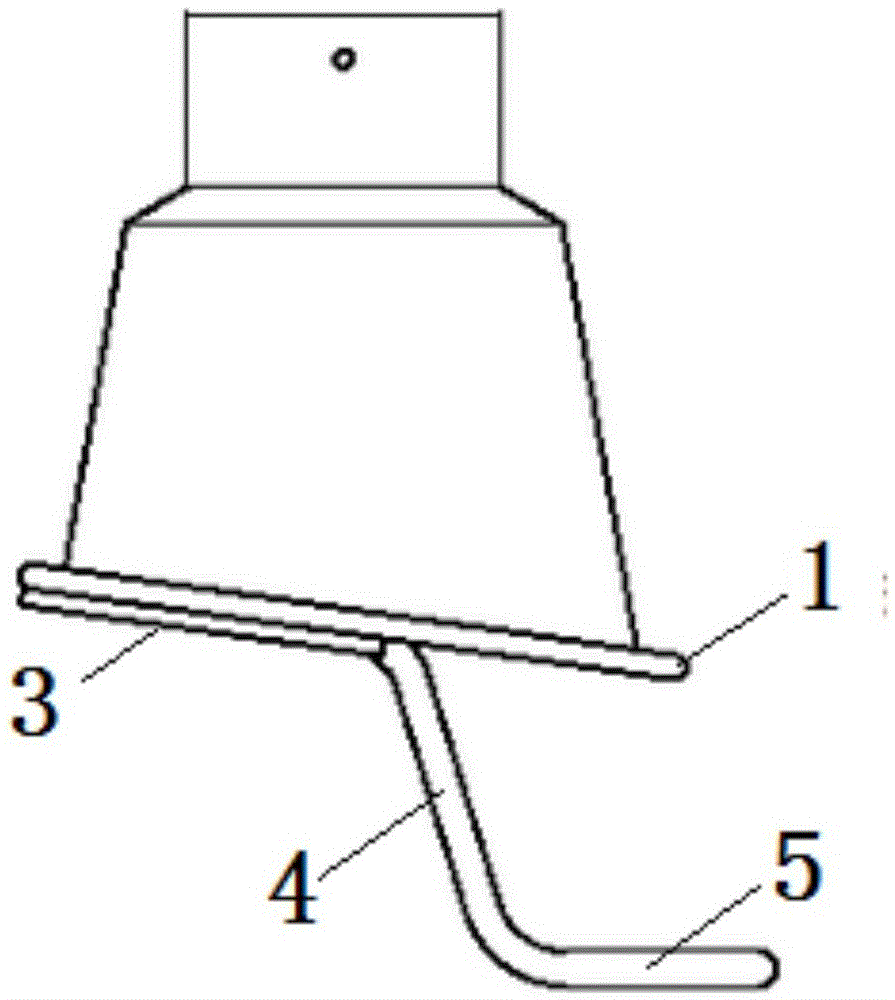

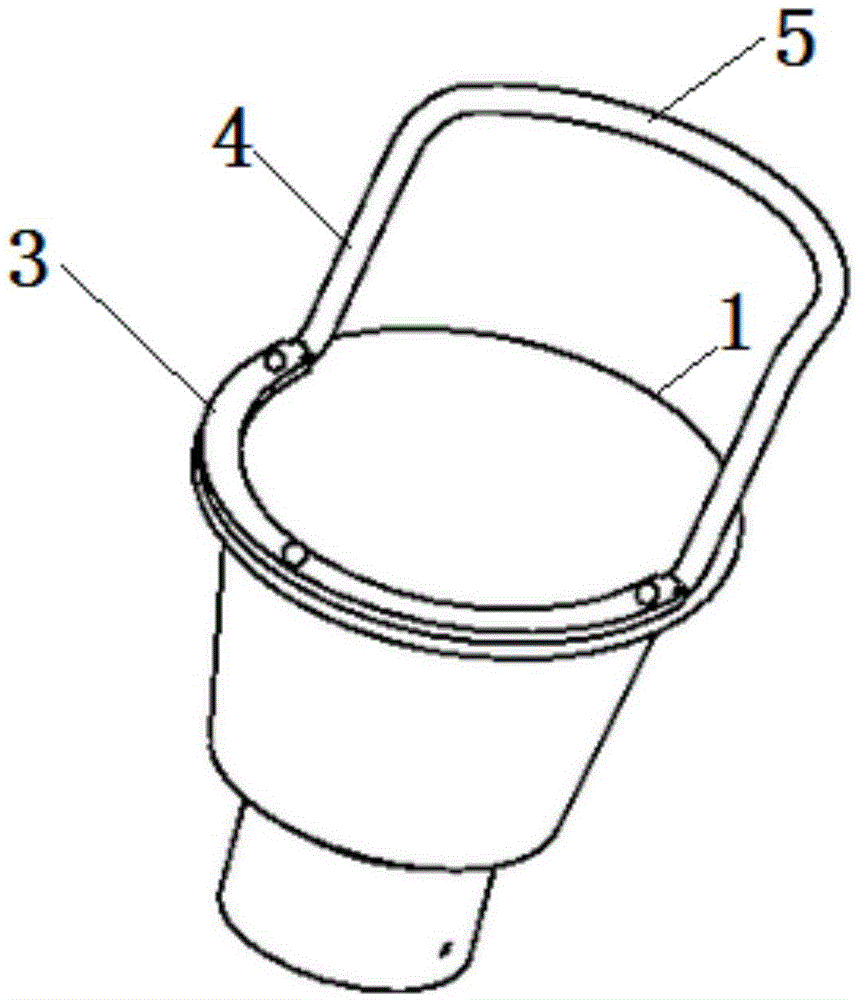

[0020] Such as figure 2 , image 3 As shown, the support frame is a bent metal ring, and the metal ring is bent into three parts: a fixed part 3, a transition part 4 and a support part 5, wherein the fixed part 3 and the free edge 1 of the cover have the same arc And fixed on the free edge 1, the support part 5 is away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com