A high-speed vibration measurement device for rolling bearings

A vibration measurement and rolling bearing technology, applied to vibration measurement, measurement device, measurement vibration and other directions in solids, can solve the problem that the detection data cannot meet the actual work needs, and achieve the effect of flexible use and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

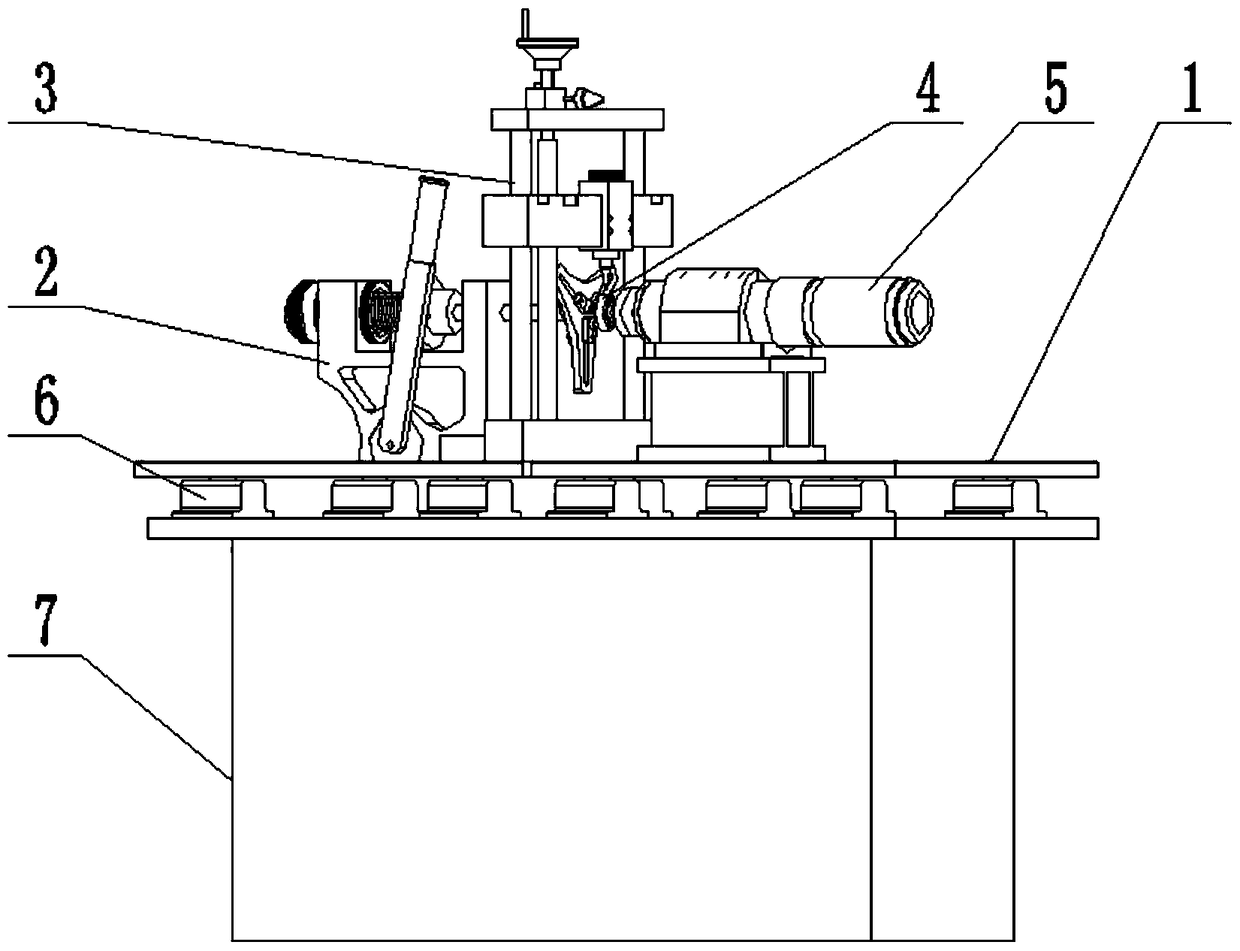

[0025] Specific implementation mode one: the following combination Figure 1 to Figure 13 Describe this embodiment, this embodiment comprises test bench 1, axial loading device 2, sensor positioning device 3, driving spindle 5 and total base 7, and described total base 7 is arranged horizontally, and described test bench 1 is arranged on total base 7 Above, the sensor positioning device 3 is arranged on the test bench 1, one side of the sensor positioning device 3 is provided with an axial loading device 2, and the other side of the sensor positioning device 3 is provided with a driving spindle 5;

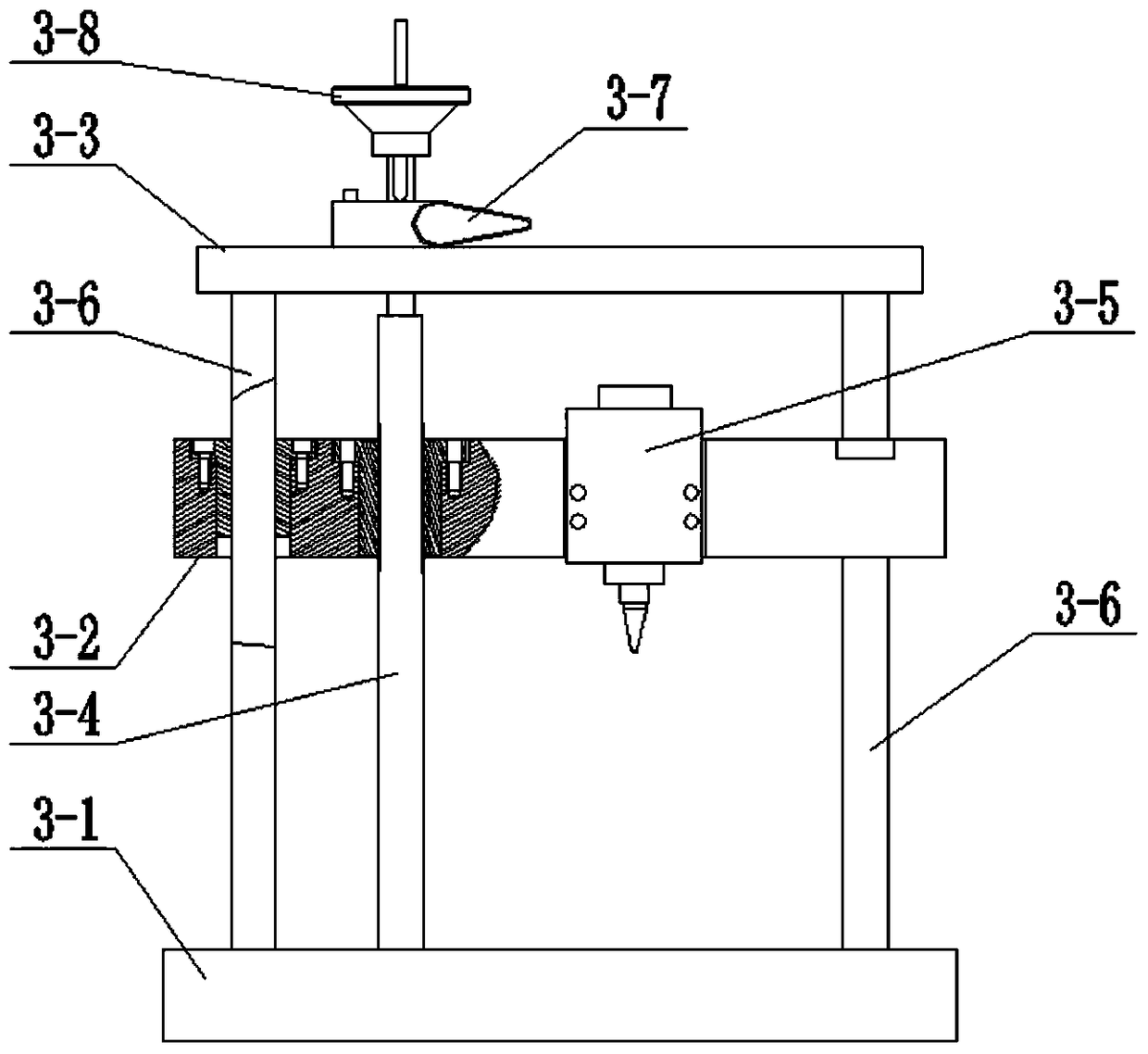

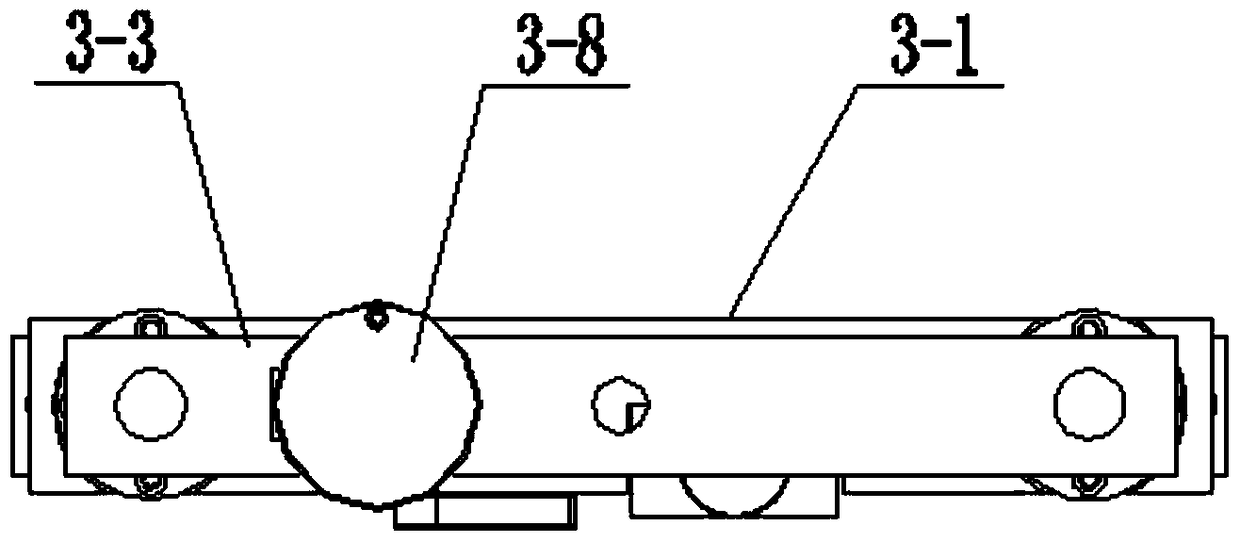

[0026] The sensor positioning device 3 includes a positioning base 3-1, a positioning beam 3-2, a beam 3-3, a lead screw 3-4, a sensor assembly 3-5 and two polished rods 3-6, and the positioning base 3-1 Fixedly connected on the test bench 1, two polished rods 3-6 are vertically arranged on the positioning base 3-1 side by side, the cross beam 3-3 is parallel to the positioning bas...

specific Embodiment approach 2

[0051] Specific implementation mode two: combination figure 1 , figure 2 and image 3 Describe this embodiment, the sensor positioning device 3 in this embodiment also includes a locking handle 3-7, the locking handle 3-7 is located on the top surface of the beam 3-3 and its grub bolt is set towards the lead screw 3-4 .

[0052] In this embodiment, the locking handle 3-7 is installed on the top surface of the crossbeam 3-3. After the positioning beam 3-2 has adjusted its position, the flat head bolt of the locking handle 3-7 withstands the lead screw 3-4, and To the effect of locking the lead screw 3-4, thereby preventing the positioning beam 3-2 from moving up and down, which is conducive to improving the positioning and detection accuracy of the sensor positioning device 3. Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0053] Specific implementation mode three: combination figure 2 Describe this embodiment, in this embodiment: the sensor positioning device 3 also includes two sliding bearings, the positioning beam 3-2 is processed with two through holes along its thickness direction, and a sliding bearing is arranged in each through hole Bearings, sliding bearings are arranged in one-to-one correspondence with the polished rods 3-6, each polished rod 3-6 is mounted on its corresponding sliding bearing, and the positioning beam 3-2 slides with the two polished rods 3-6 through two sliding bearings Cooperate. Other unmentioned structures and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com