Motor load test tooling

A technology of load testing and tooling, applied in the direction of motor generator testing, etc., can solve the problems of cumbersome testing process, inflexibility, and inability to adjust the load size at any time, and achieve the effect of optimizing testing conditions and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

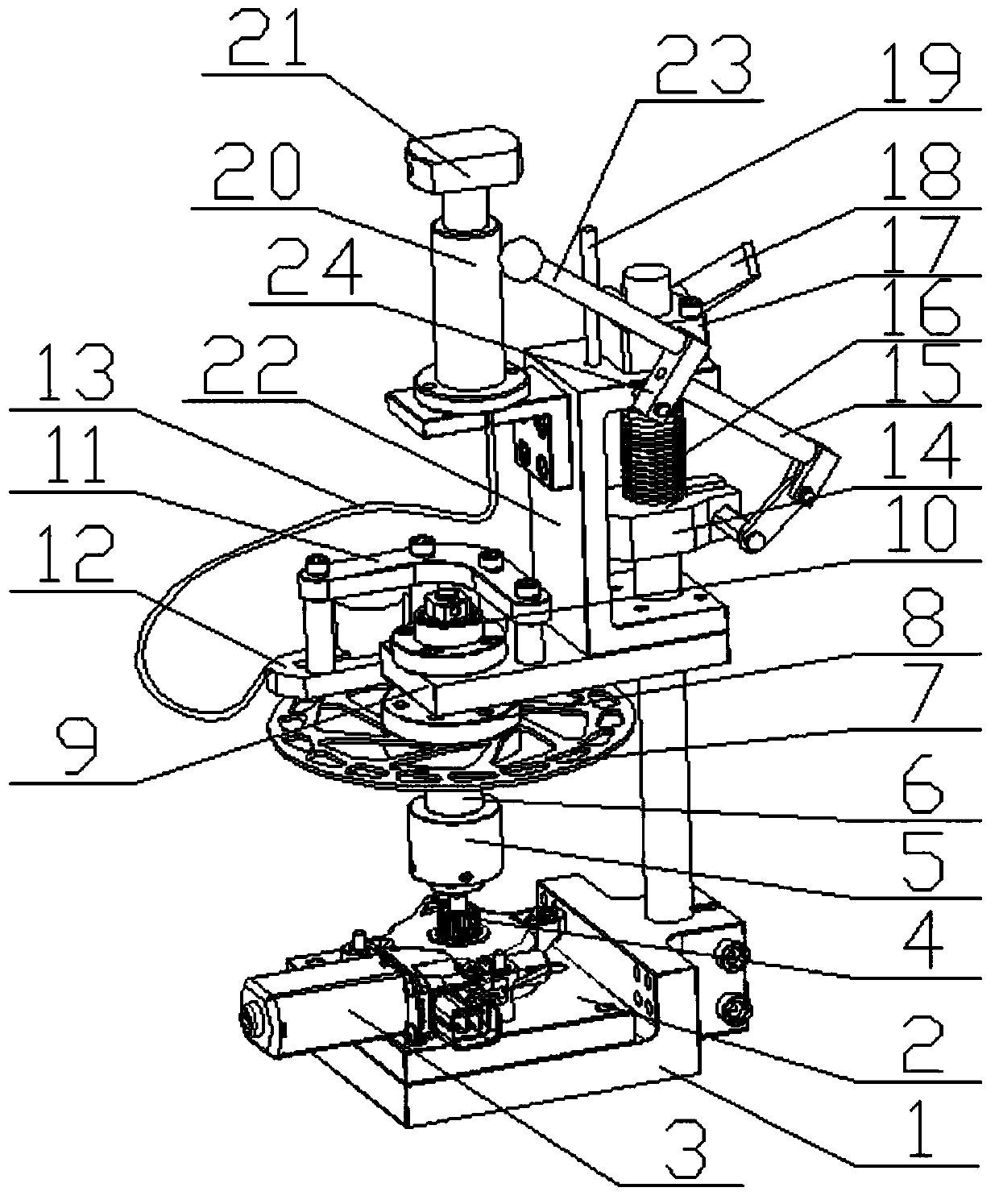

[0017] Such as figure 1 As shown, the present invention proposes a motor load test tool, including an insulating plate to prepare a tool base 1, a test motor mount 2 and a vertically arranged cylindrical connecting column are arranged on the tool base 1, and a test motor mount 2 is placed on the test motor. Motor 3, the test motor 3 is provided with a test motor output shaft 4 arranged vertically upwards, the connecting column is provided with a moving assembly, the moving assembly is provided with a test motor driven shaft bearing mount 10 and a brake assembly, and the test motor driven shaft The bearing mount 10 is connected to the driven shaft 6 of the test motor through bearings, the brake assembly is connected to the driven shaft 6 of the test motor, and the bottom of the driven shaft 6 of the test motor is provided with an output shaft connection device 5, which adopts Coupling, the top of the test motor output shaft 4 is inserted into the output shaft connection device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com