Late-dense-simplified cotton cultivation method adopting chemical topping

A cultivation method and chemical technology, applied in botany equipment and methods, chemicals for biological control, cultivation, etc., can solve the problems of premature aging, large manual investment, cumbersome operation, etc., and achieve the improvement of chemical control effect and reduce Labor investment and good effect of chemical control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

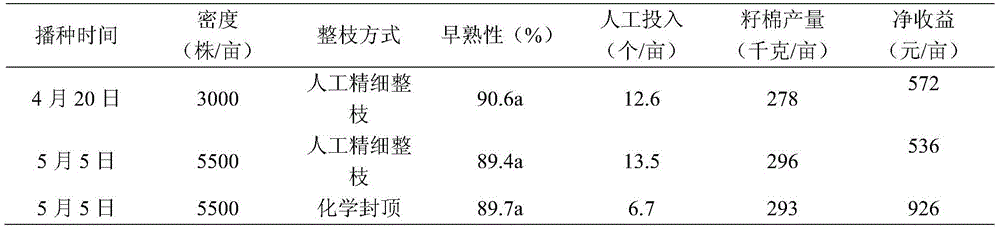

[0023] This experiment took cotton variety K836 as the test material, and was carried out at the Linqing Experimental Station of Shandong Cotton Research Center for two consecutive years from 2014 to 2015. Set regular time for sowing (April 20) + medium density (3000 plants / mu) + manual fine pruning, late spring sowing (May 5) + high density (5500 plants / mu) + manual fine pruning and late spring sowing (5 May 5th) + high density (5500 plants / mu) + chemical capping 3 treatments, repeated 3 times, a total of 9 plots, with an area of 40m2 2 , planted in 6 rows with equal row spacing, and the row spacing is 76cm. The conventional sowing time is April 20, and the late spring sowing time is May 5. Cover with two rows of one film with a wide film (120cm). Dingmiao at the 2-3 leaf stage. Among them, artificial fine pruning during the whole growth period includes removing leaf branches, removing redundant buds, removing leaf branch tops, fruit branch tops and main stem tops, removi...

Embodiment 2

[0029] In the first ten days of May, according to the weather conditions, precision sowing was carried out by using machinery. The sowing, film covering and fertilization were completed at one time, and the seedlings were fixed at the 2-3 leaf stage. For more than 1,000 acres, only this method is used for chemical topping throughout the growing season, and no other pruning and topping measures are taken.

[0030] The specific operation method of chemical capping is as follows: select 25% benzedramine aqueous solution produced by Sichuan Guoguang Agrochemical Co., Ltd., 25% flubenzamine emulsifiable concentrate produced by Zhejiang Hetian Chemical Co., Ltd. and Shandong Jinzhengda Ecological Engineering Co., Ltd. N amount 46% urea. According to the amount of application per mu, mix different ratios of mepezine + flumetamine medicinal liquids, which are respectively: medicinal solution (1) 8-10ml 25% mepimetamine + 4-5ml 25% flumetamine, mixed with 20kg of water; Medicinal solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com