An anti-jamming mechanism for the support in the thimble plate

An anti-seize and thimble plate technology, which is applied in the field of anti-seize mechanisms in the thimble plate, can solve the problems of mold thermal expansion, jamming, temperature rise, etc., and achieve the effect of simple structure and preventing thermal expansion and jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

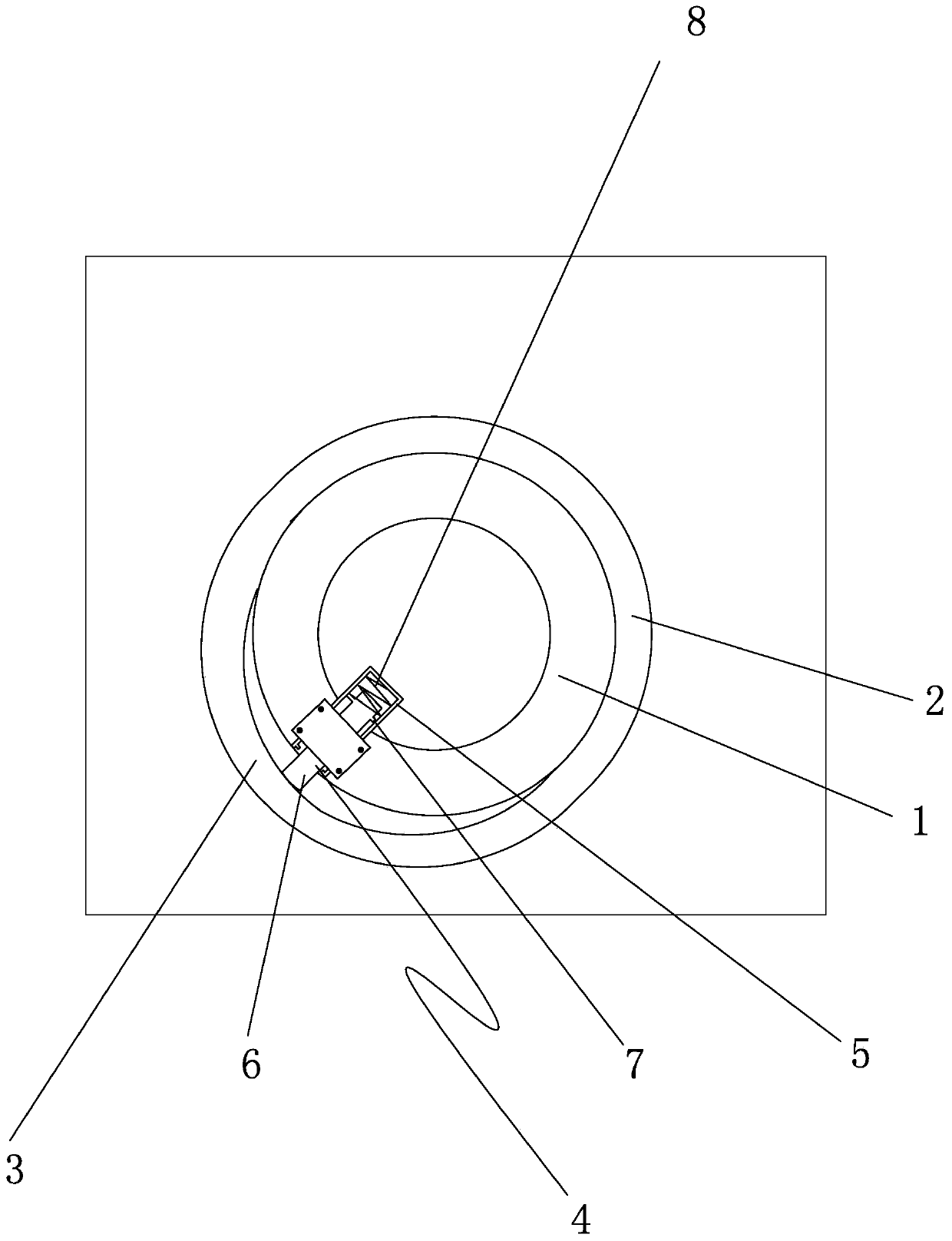

[0016] Such as figure 1 The illustrated anti-seize mechanism for the toss in the ejector plate includes a guide post 1 arranged on the ejector plate of the mold and a guide sleeve 2 arranged in the mold, and one side of the guide sleeve 2 is provided with a function to prevent the guide pin from The column 1 expands when heated and is stuck in the outer offset part 3 inside the guide sleeve 2 .

[0017] In the present invention, the distance between the inner wall of the outer offset part 3 and the outer wall of the guide post 1 is 0.2-0.5 mm.

[0018] In the present invention, the two end surfaces of the outer offset part 3 and the center of the enclosed guide post 1 form an included angle of 45°.

[0019] In the present invention, an elastic constant pressure column device 4 is provided inside the guide column 1 , and one end of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com