New type ink bag and sprayer combination device

A technology of combining device and ink bag, applied in printing and other directions, can solve problems such as insufficient connection and assembly, affecting printing quality, easy ink leakage, etc., to achieve the effect of improving adaptability, simple structure and solving loose connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

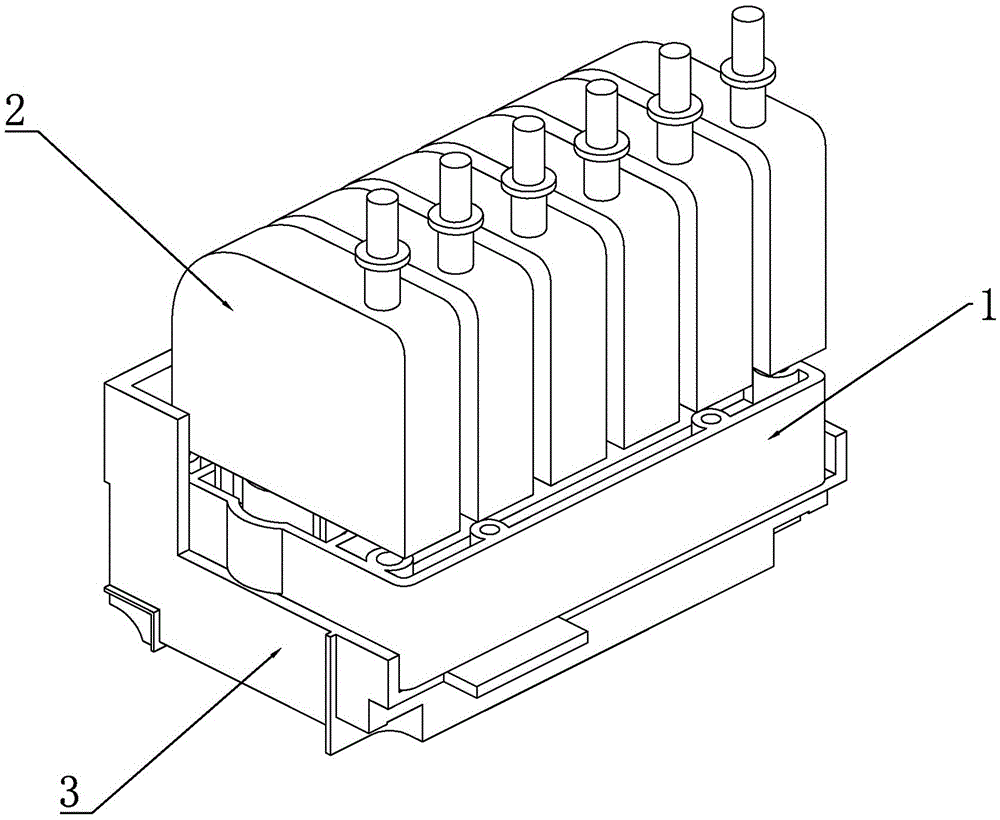

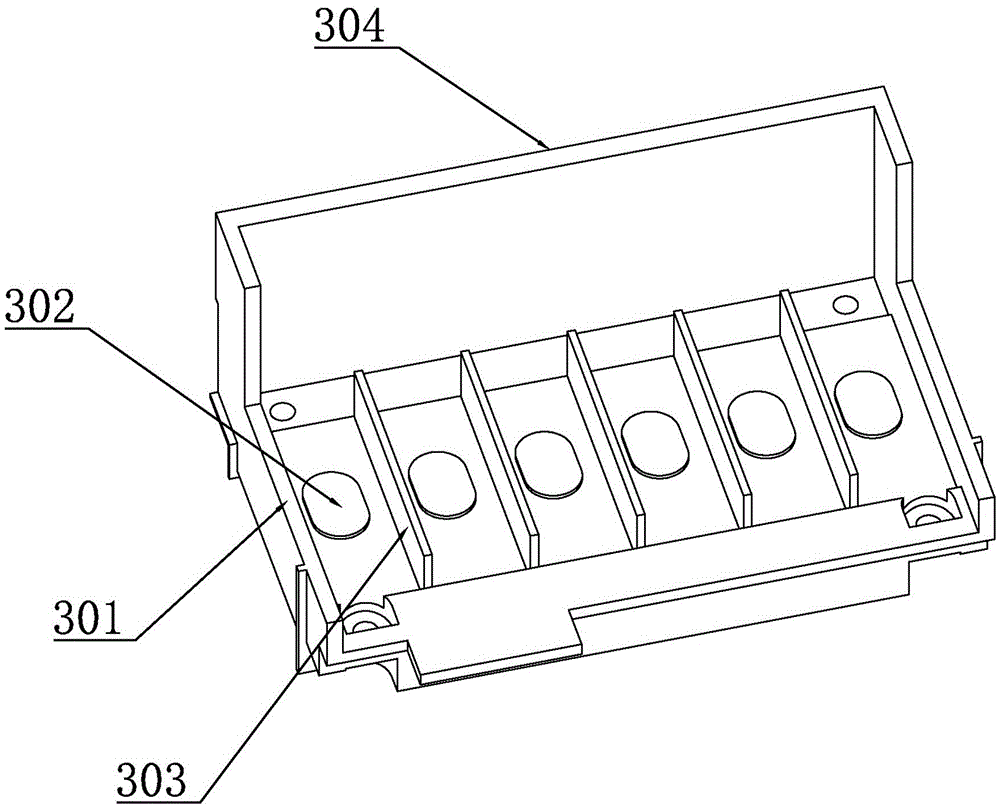

[0018] Example 1 A new type of ink bag and nozzle combination device, see figure 1 , 3 , 4, 6, 7: Including ink sac 2, nozzle 3, and nozzle cover 1, several ink sacs 2 are correspondingly assembled on the nozzle 3 through the nozzle cover 1; the upper end of the nozzle cover 1 is provided with a connecting groove 101 corresponding to the ink outlet 201 of the ink bag The bottom of the connection groove 101 is provided with an ink guide hole 105 extending to the lower end surface of the nozzle cover 1 , and the ink guide hole 105 is correspondingly connected to the ink inlet port 302 of the nozzle head 3 .

[0019] Connecting the ink bag 2 and the nozzle 3 through the nozzle cover 1 improves the adaptability of the ink bag 2 and the nozzle 3, so that the nozzle 3 can match more types of ink bags; the structure is simple, the installation is convenient, the connection is tight, and the solution is effective. The problem that the ink bag 2 is not tightly connected with the noz...

Embodiment 2

[0020] Example 2 A new type of ink bag and nozzle combination device, see Figure 1-7 : Including ink bag 2, nozzle 3, nozzle cover 1, several ink bags 2 are correspondingly assembled on the nozzle 3 through the nozzle cover 1; the upper end of the nozzle cover 1 is provided with a connecting groove 101 corresponding to the ink outlet 201 of the ink bag, and the bottom of the connecting groove 101 is provided There is an ink guide hole 105 extending to the lower end surface of the nozzle cover 1 , and the ink guide hole 105 is correspondingly connected to the ink inlet port 302 of the nozzle head 3 .

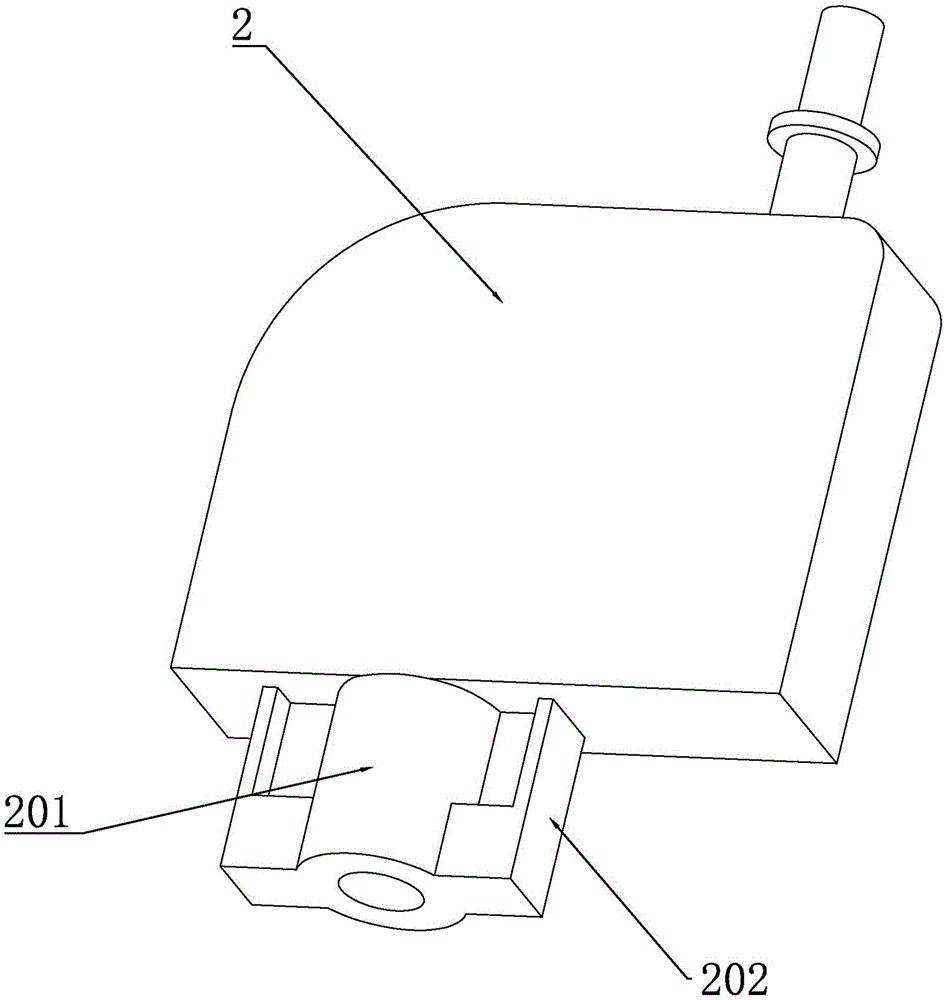

[0021] Preferably, the ink outlet 201 of the ink bag 2 is a hollow column, and the side wall of the ink outlet 201 is correspondingly provided with two vertical connecting ribs 202, and the upper end of the nozzle cover 1 is provided with mutually independent connection grooves corresponding to the ink outlet 201 101; the ink guide hole 105 at the bottom of the corresponding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com