Lubricating oil channel structure of internal combustion engine

A lubricating oil channel and internal combustion engine technology, which is applied in the direction of engine cooling, mechanical equipment, engine components, etc., can solve the problems of reducing the output power of the internal combustion engine, reducing the charging efficiency, etc., and achieve the effect of reliable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

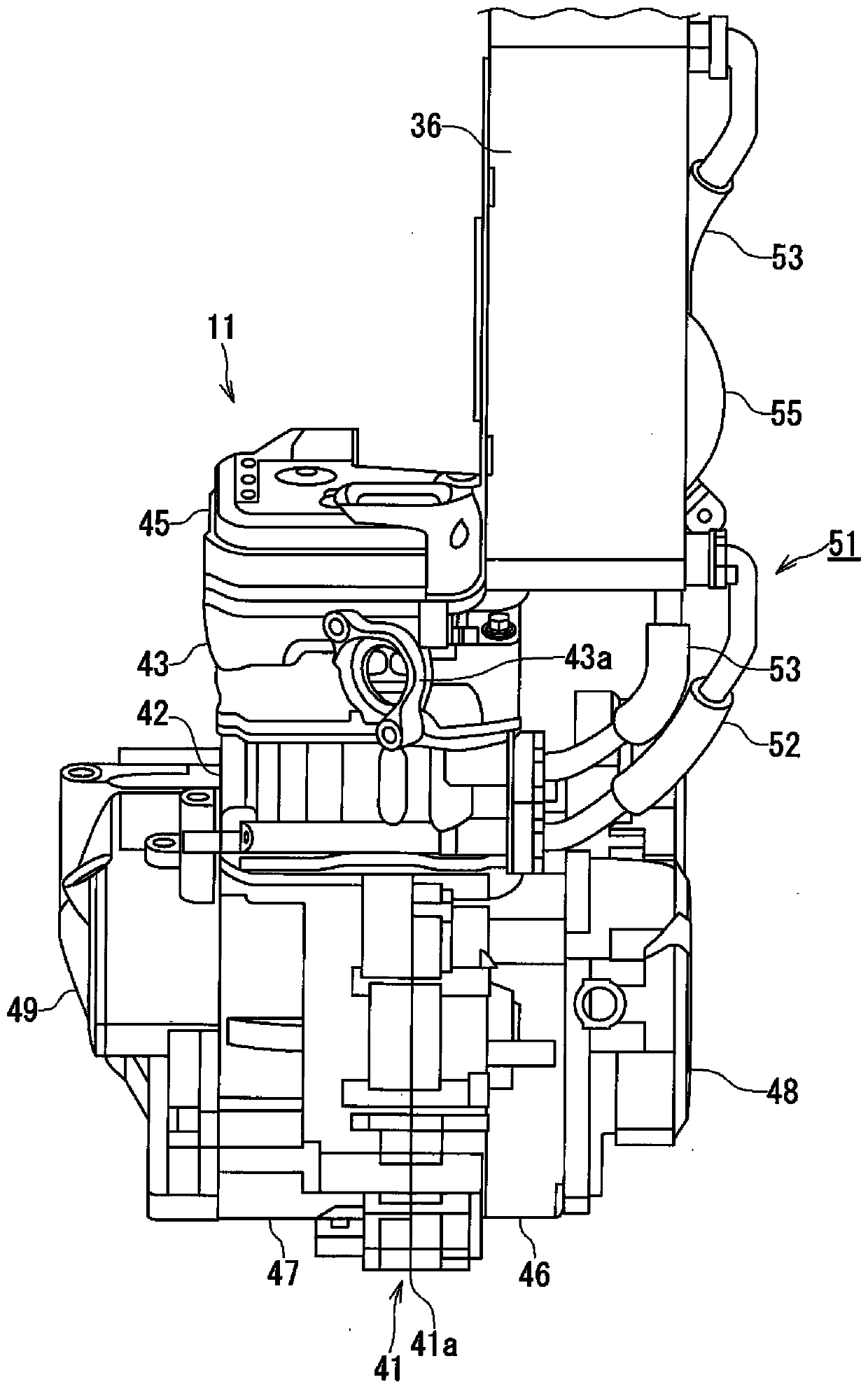

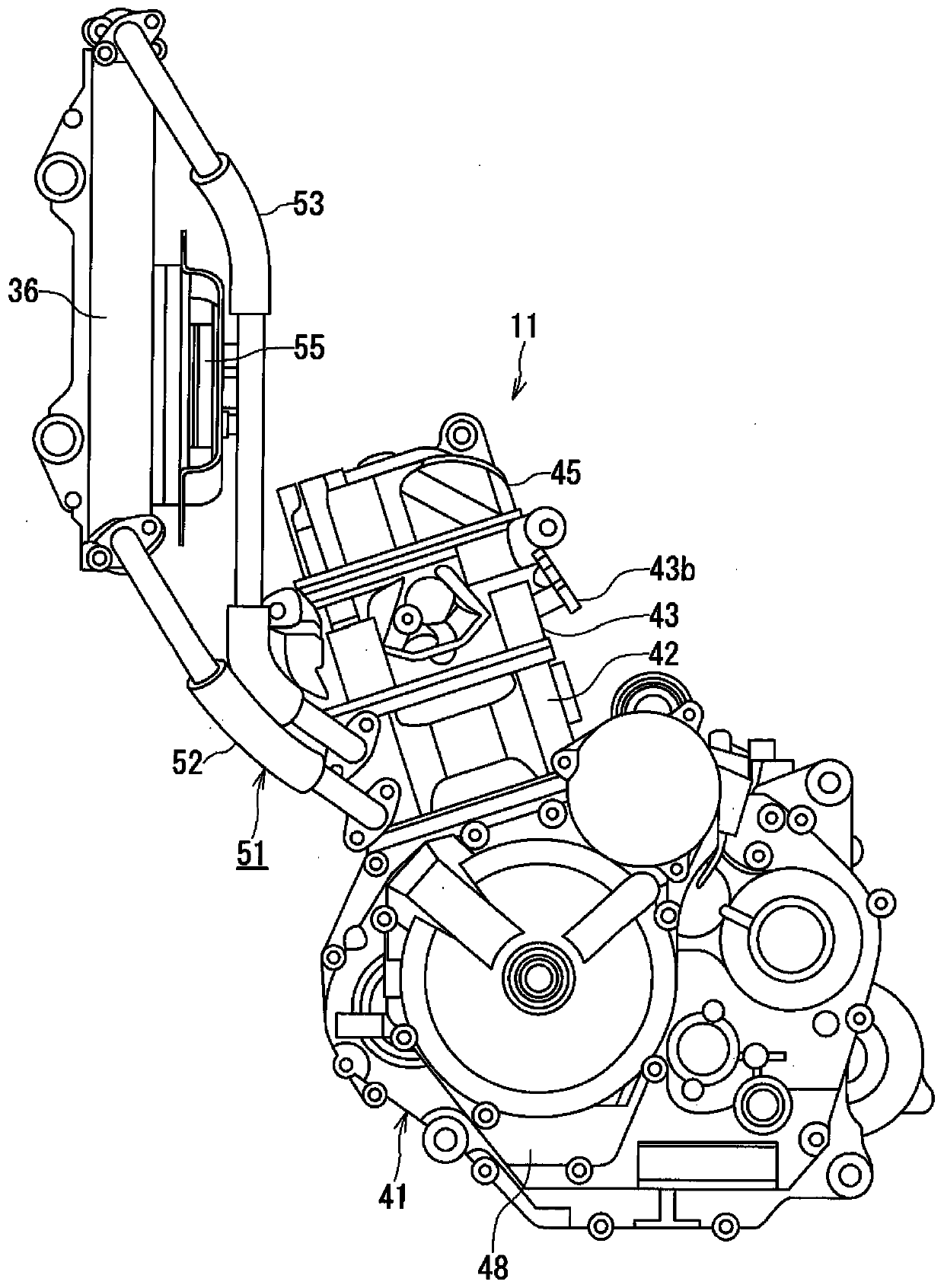

[0027] refer to Figures 1 to 9 An embodiment of the lubricating oil passage structure of an internal combustion engine according to the present invention will be described.

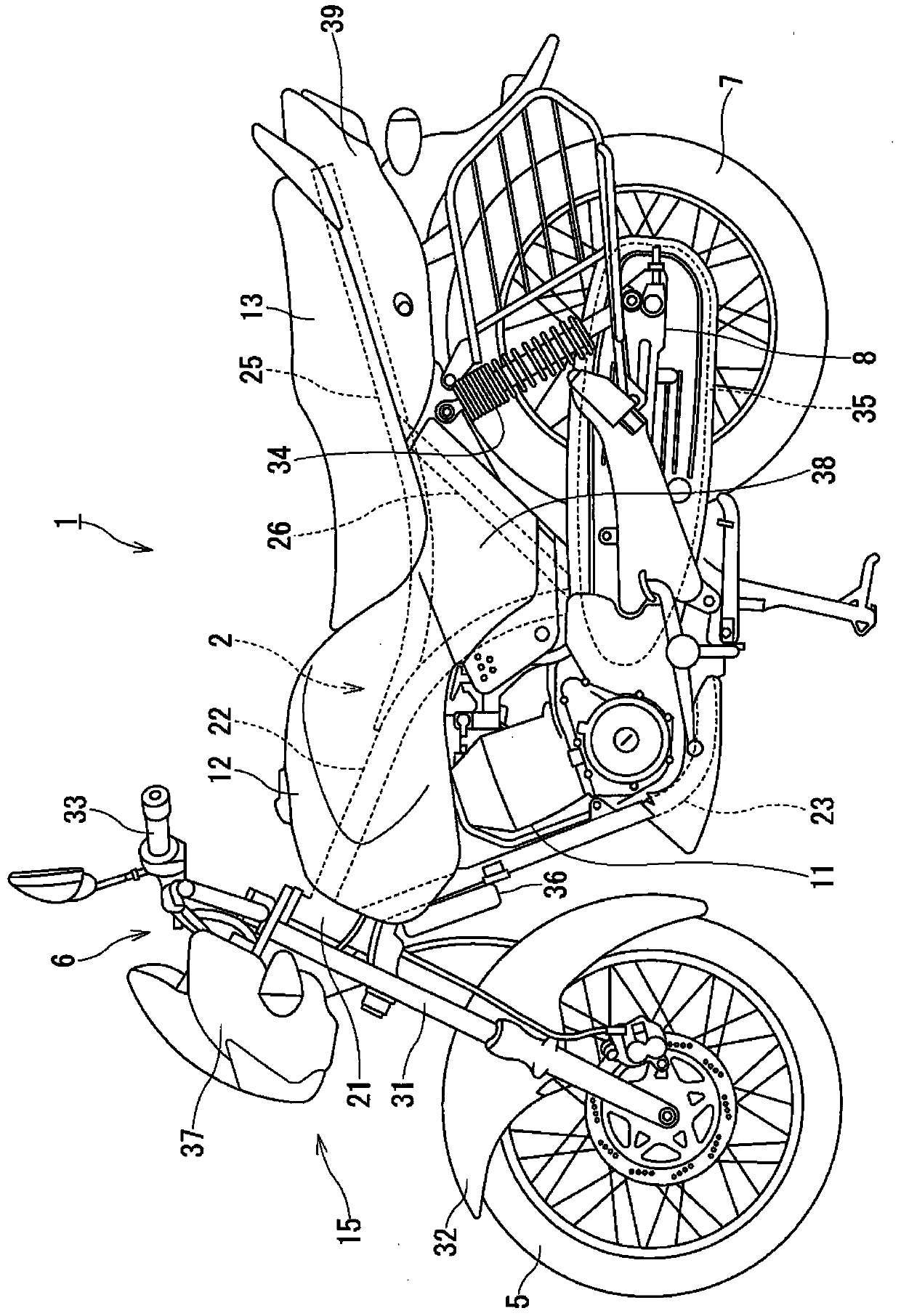

[0028] figure 1 is a left side view showing an example of a motorcycle to which a lubricating oil passage structure for an internal combustion engine according to an embodiment of the present invention is applied.

[0029] Note that in this embodiment, the representations of front and rear, up and down, left and right refer to the perspective of the driver on the motorcycle 1 .

[0030] Such as figure 1 As shown, the motorcycle 1 according to this embodiment includes: a body frame 2, which extends from front to rear; a front wheel 5, which is arranged in front of the body frame 2; a steering mechanism 6, which is arranged on the body The front end portion of the frame 2 and rotatably supports the front wheel 5; the rear wheel 7 is arranged behind the vehicle body frame 2; the swing arm 8 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com