Continuous casting machine fan-shaped section frame displacement monitoring system

A continuous casting machine segment and displacement monitoring technology, applied in the direction of measuring devices, using electromagnetic means, instruments, etc., can solve the problems of time-consuming and laborious, affecting the online state control of the segment, reducing the quality of continuous casting slab products, etc., to ensure On-line status control, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

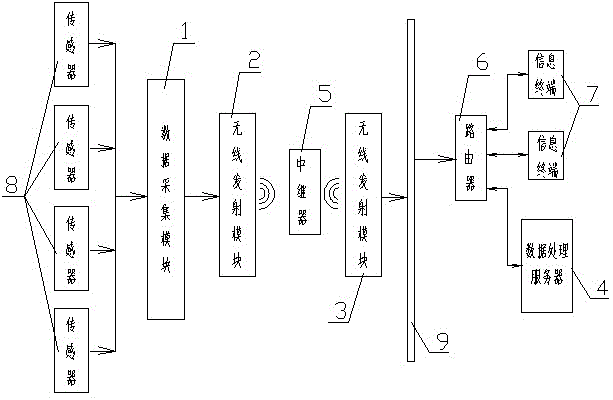

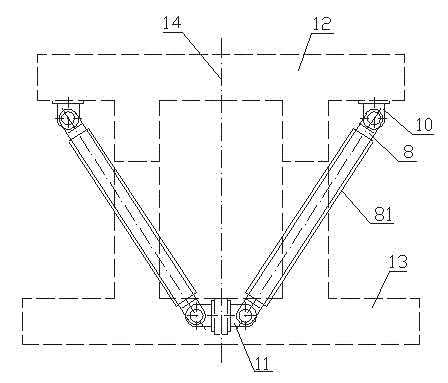

[0014] Such as figure 1 As shown, the continuous casting machine segment frame displacement monitoring system of the present invention includes a data acquisition module 1, a wireless transmitting module 2, a wireless receiving module 3, a data processing server 4 and four magnetostrictive displacement sensors 8, and the four magnetostrictive Displacement telescopic sensors 8 are respectively arranged on both sides of the sector frame and arranged in a V shape, and the signal output terminals of the four magnetostrictive displacement telescopic sensors 8 are connected to the input terminals of the data acquisition module 1, and the signal output terminals of the data acquisition module 1 are The output terminal is connected to the input terminal of the wireless transmitting module 2 , the wireless receiving module 3 receives the signal transmitted by the wireless transmitting module 2 and the output terminal is connected to the data processing server 4 .

[0015] further, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com