Device for monitoring stability of optical path of photoetching equipment

A lithography equipment and a technology for monitoring light, which are applied in microlithography exposure equipment, photolithography exposure devices, and testing optical properties, etc., can solve the problems of inability to monitor in real time, cumbersome optical path procedures and equipment, and increased production costs Risk and other issues, to avoid downtime monitoring conditions, reduce production costs, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

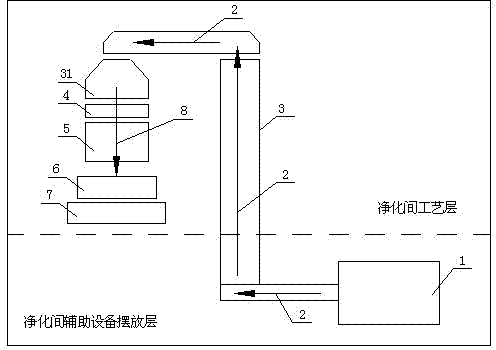

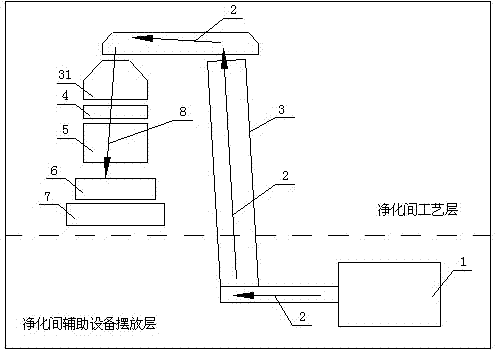

[0028] Figure 4 It is a structural schematic diagram of the device for monitoring the stability of the optical path of the lithography equipment in the present invention;

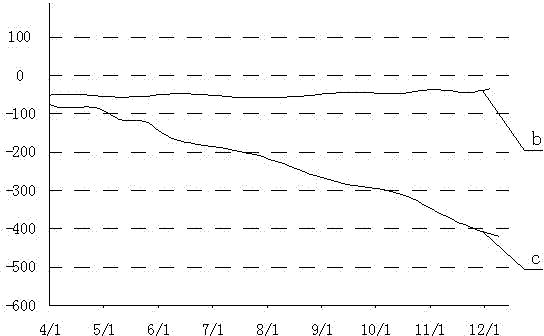

[0029] Such as Figure 4 As shown, the present invention is a device for monitoring the stability of the optical path of lithography equipment. A level 9 is provided on each optical path lens 3 passing by the illumination optical path 2, and a level 9 is also arranged on the optical path lens 31 passed by the projection optical path 3. At the same time, a level 9 is also set on the shock absorber 7 of the lithography machine; wherein, the level 9 is a mechanical level or an electronic level, and each level 9 is connected to the lithography information management system (not shown in the figure). The information management system can check the real-time data of each level 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com