Method and device for detecting scratches on the surface of an optical element

A technology of optical components and detection methods, applied in image data processing, instruments, calculations, etc., can solve problems such as discontinuity of the surface of large-diameter optical components, and achieve the effects of strong scalability, high accuracy and fast detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A detection method for discontinuity and bending scratches on the surface of the optical element of the present invention is mainly implemented by a computer.

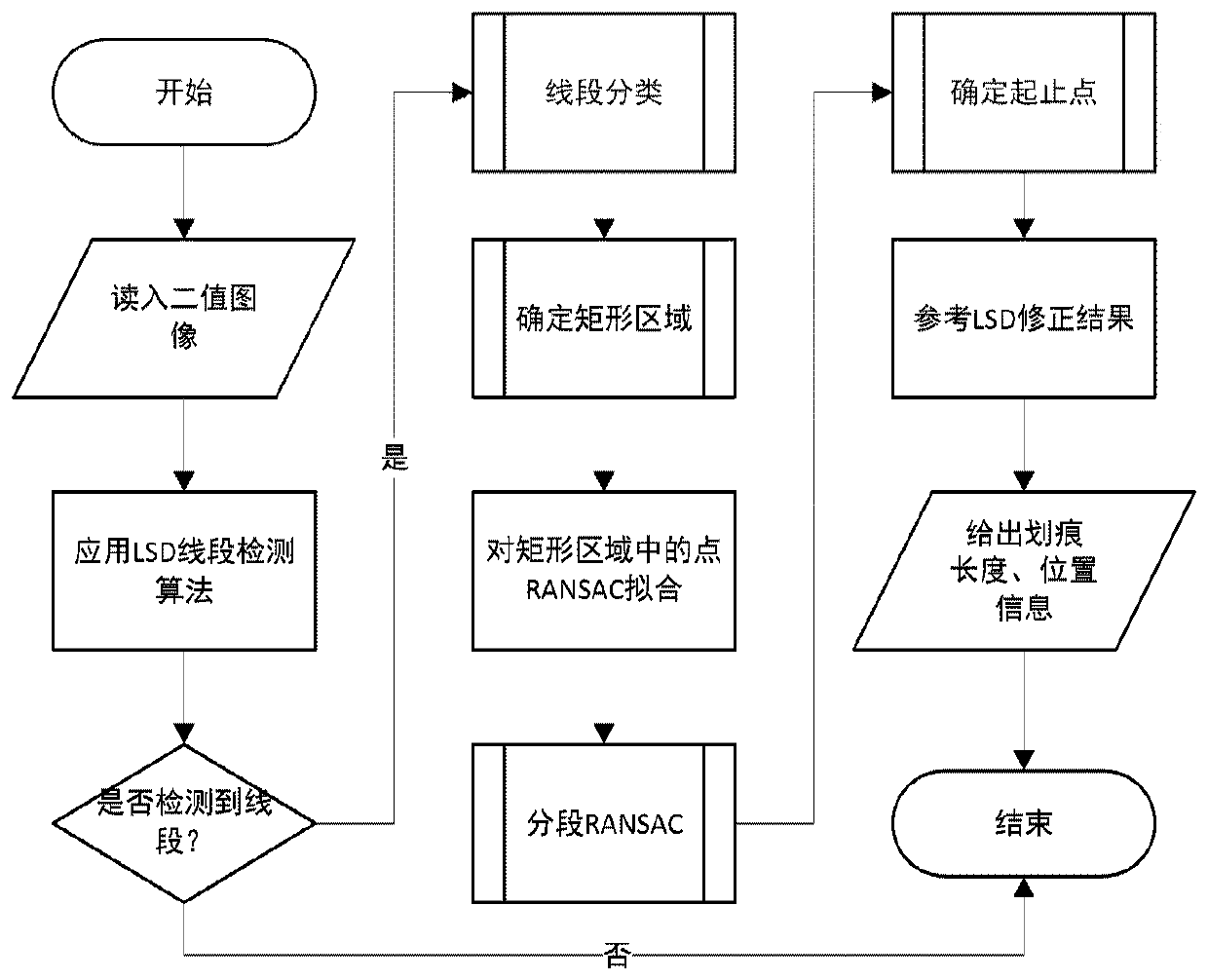

[0030] Such as figure 1 As shown, a method for detecting scratches on the surface of an optical element in an embodiment of the present invention, the specific operation steps are as follows:

[0031] 1) Binarize the image on the surface of the optical element, and store it in the hard disk of the computer with the number i (i=1, 2...);

[0032] 2) Apply the LSD (Line Segment Detector) algorithm to the i-th image in step 1) to obtain a set of line segments detected by the algorithm; this set of line segments can provide the position information of the scratch and its approximate direction, each line segment Including: start point coordinates and end point coordinates. This step obtains preliminary scratches on the surface of the optical element according to the image;

[0033] 3) classify all the line segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com