An Adaptive Installation Error Slip Ring Connecting Device

A connection device and installation error technology, which is applied to the two-part connection device, the parts of the connection device, and the connection, can solve problems such as poor workmanship, hidden dangers of interference, and damage to the structure of the confluence ring, and achieve the requirements of reducing parallelism and improving Manufacturability, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical content, structural features, objectives and effects of the present invention in detail, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

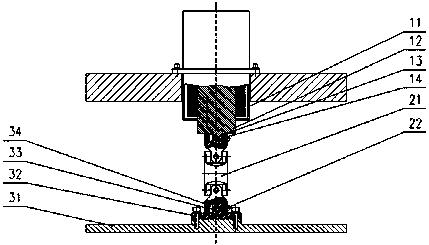

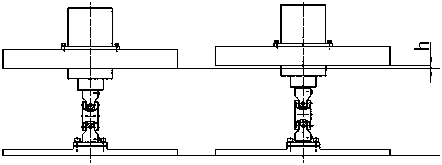

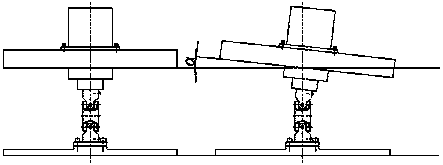

[0016] see Figure 1 to Figure 4 , the present invention is an adaptive installation error slip ring connection device, including slip ring, universal joint, and rotary body. The slip ring includes a slip ring shell 11, a slip ring rotor shaft end 12, a keyway 13, and a key 14, and the slip ring rotor shaft end 12 is φ20×17. The universal joint includes a double precision universal joint 21 and a set screw 22 . The revolving body includes a revolving body 31, a revolving body shaft end 32, a keyway A33, and a key A34, and the revolving body shaft end 32 is φ20×17. Key 14 and key A34 are GB / T1096-2003 key 6×16, set screw 22 is M4×15, and the assembly relationship between slip ring housing 11 and slip ring rotor shaft end 12 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com