Wall lead-through

A technology of through-wall bushings and components, applied in the direction of pipes, pipes/pipe joints/pipes, electrical components, etc., can solve the problems of flange installation cost and difficulty, and achieve the effect of simple sealing and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

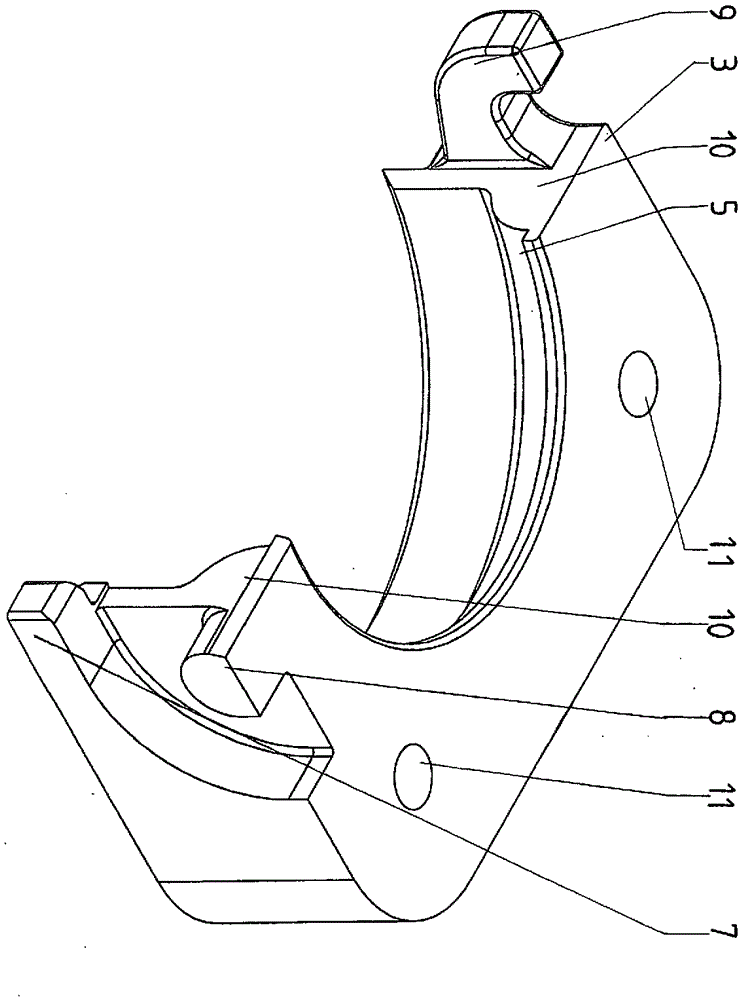

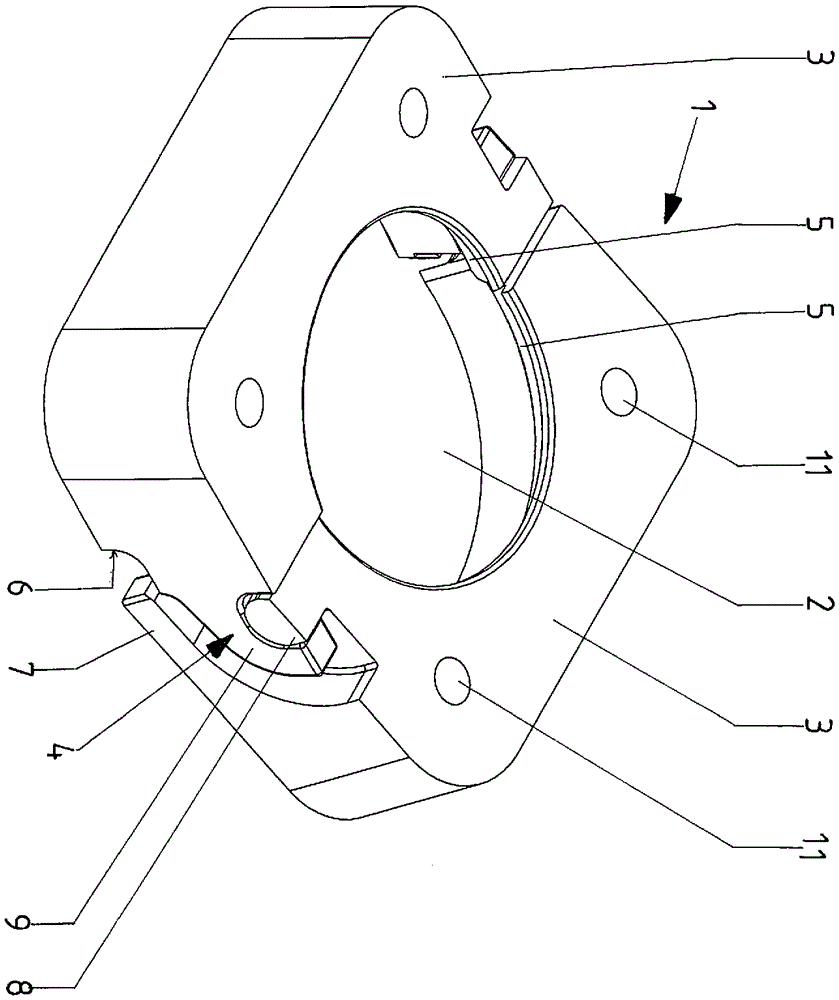

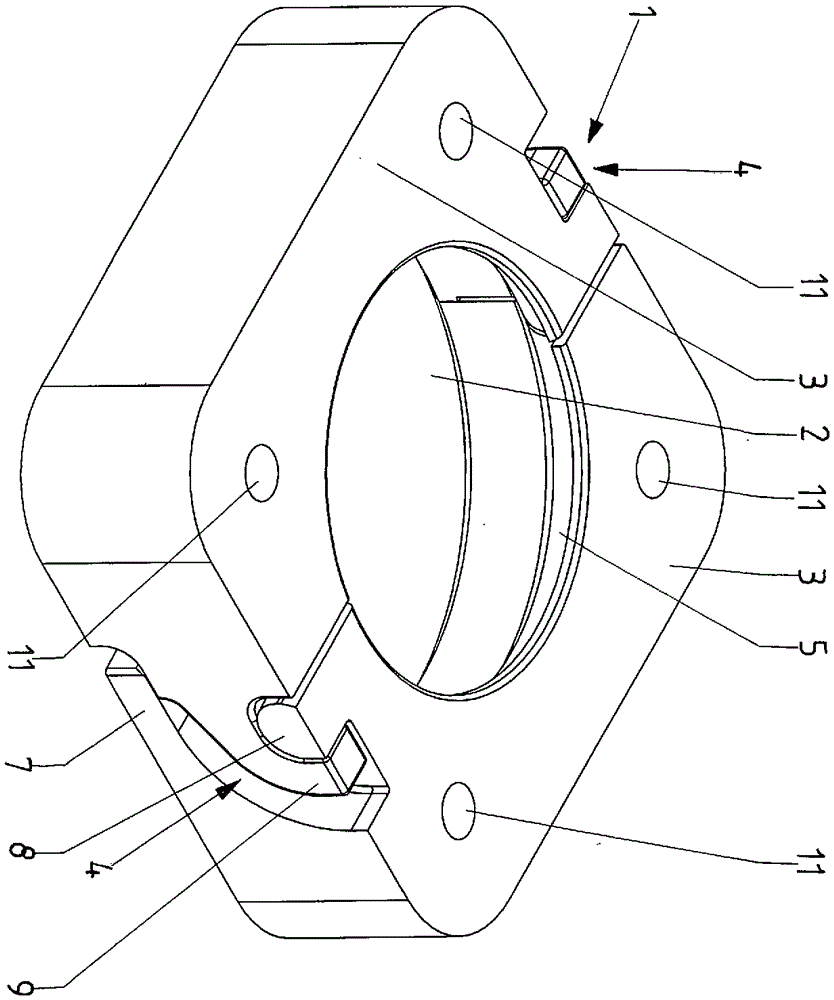

[0031] Important elements of the wall bushing are shown in the drawing. Such wall bushings are used for routing elongated components such as pipes, lines, cables or the like through the walls of devices, housings or components provided with walls. The corresponding walls have through holes. At said wall, the flange 1 is fastened by means of fastening means. The flange has a hole 2 coaxial with the through hole of the wall. During assembly, the flanges are fastened to the corresponding housing wall. Any type of elongated part can be laid through the hole 2 of the flange 1 and the through hole of the housing. In order to allow a subsequent assembly of a flange of this type when an installation is already present, for example if the flange is damaged or destroyed, it is provided according to the invention that the flange 1 is composed of two The hole 2 is formed by half-flange parts 3 , which are connected to one another by means of molded connection means 4 . Here, the half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com