Ceramic teapot with scripts and paintings on inner wall and manufacturing method

A production method, calligraphy and painting technology, applied in the direction of household containers, etc., can solve the problems of non-appearance, etc., and achieve the effect of unique craftsmanship, novel shape and full of novelty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The structure and manufacturing process of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the scope of the present invention is not limited to these examples.

[0042] The making and preparation of the clay is the same as traditional, and this process is omitted. The technological process and parameter requirements for depicting mud filling are as described above.

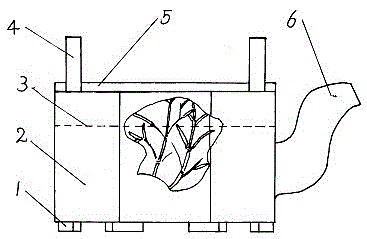

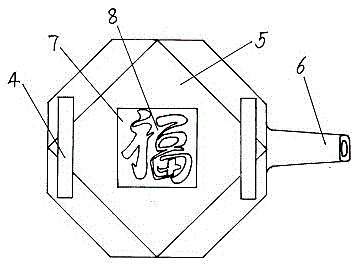

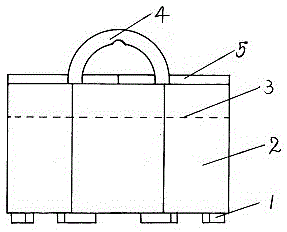

[0043] Such as Figure 1-6 As shown, the pot wall 2 is exactly eight sides of the regular octagon, and is divided into eight small pieces with the same size and shape when making the pottery blank assembly. The calligraphy and painting production process is similar to that on the traditional outer wall. First, the painter and calligrapher use ink and other pigments to make calligraphy and painting on the wall. After the calligraphy and painting are completed, a carving knife is used to carve (dig) the clay covered by the pigment to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com