a dishwasher

A dishwasher and washing tub technology, which is applied in the washing machine/washing machine for tableware, parts of the washing machine/rinsing machine for tableware, cleaning equipment, etc., can solve the corrosion of the rotating shaft, increase the manufacturing cost of the dishwasher, and the pressure deviation and other problems, to achieve the effect of reducing the requirements for production and assembly, avoiding local rapid aging, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

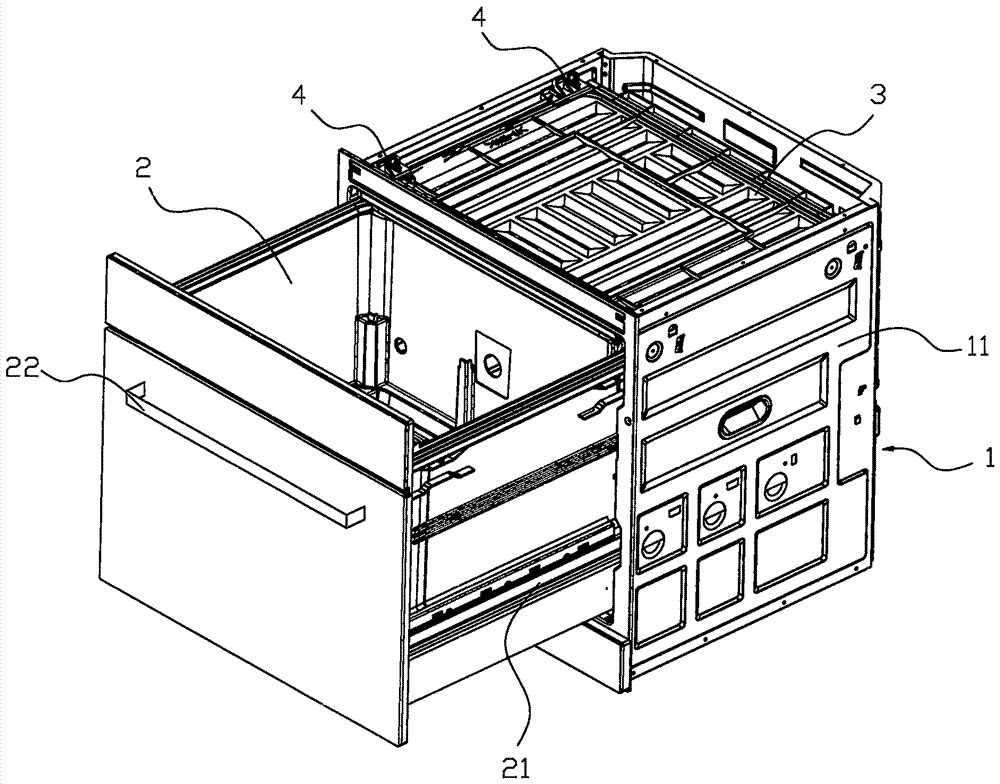

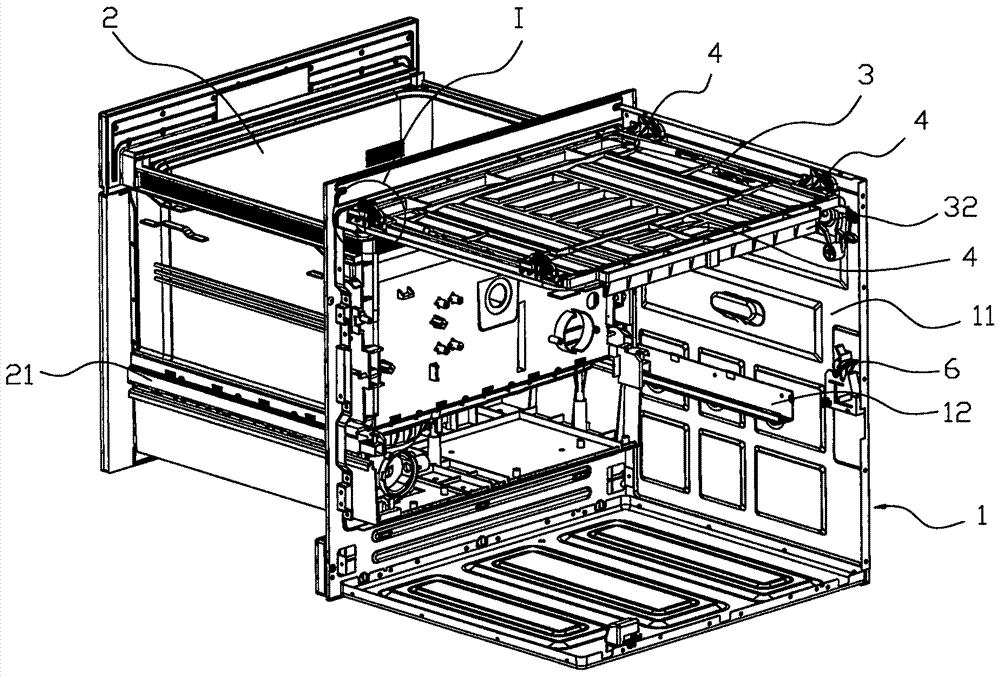

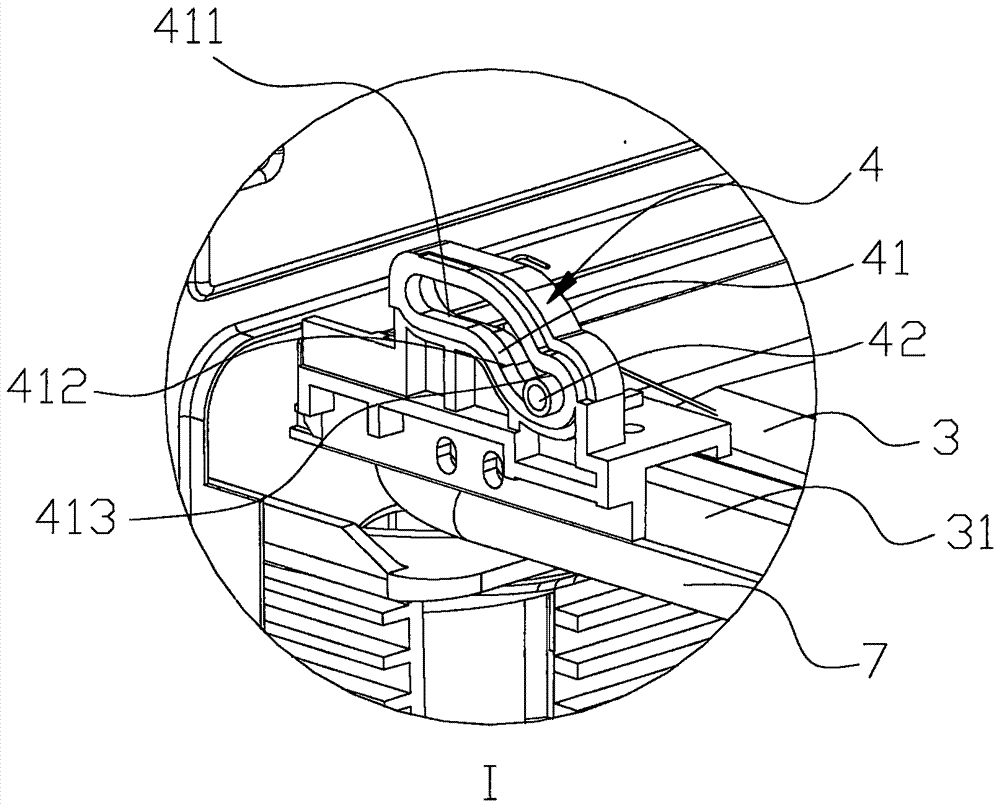

[0030] A kind of dishwasher of the present invention such as Figure 1-6 As shown, it includes: box body 1, washing bucket 2, washing bucket 2 is installed in the box body 1, there is a slide rail between the washing bucket 2 and the box body 1, and the slide rail 12 on one side of the box body 1 is installed in the box body On the side plate 11, the washing bucket slide rail 21 is installed on the outer surface of the two side walls of the washing bucket 2, and the handle 22 on the front outer surface of the washing bucket is pulled or pushed, and the slide rail 12 and the washing bucket slide rail 21 slide relative to each other, and the washing bucket 2 Slide into the box body 1 or slide out of the box body 1 along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com