Novel oil-gas well filling system and application method of same

A technology for oil and gas wells and wellbore, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc. It can solve problems such as failure to achieve, failure of semi-permeable sealing and flow control technology, and inability to run liquid expansion packers. problems, to achieve the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

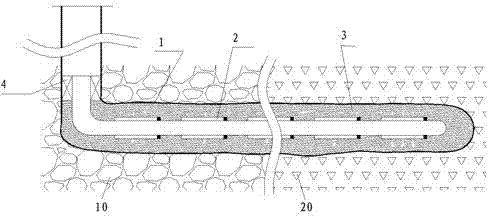

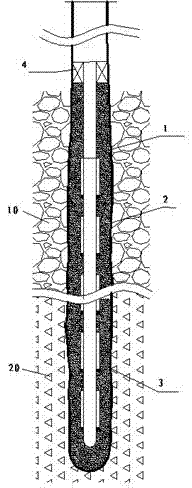

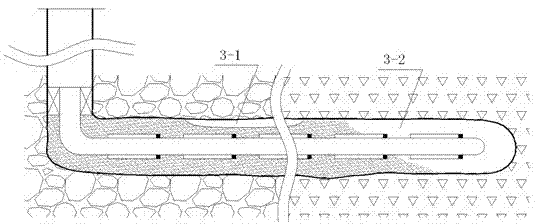

[0105] Such as Figure 5 As shown, the present invention provides a new oil and gas well filling system. The oil and gas well filling system includes the well wall of the oil and gas well and the well entry string that is lowered into the oil and gas well. Tube string for filter 5-2. An annulus is formed between the well entry pipe string and the well wall; at least one controllable circulation device 5-1 is arranged on the well entry pipe string.

[0106] The controllable circulation device is installed on the entry pipe string at the most toe end of the oil and gas well.

[0107] The controllable flow device has two states:

[0108] (1) Open state: during the initial filling, the controllable circulation device is in the open state, so that a certain amount of fluid carrying filling particles can be guided to the position of the controllable flow device, that is, the toe end of the oil and gas well; (2) Closed state:

[0109] The main part of a new oil and gas well fillin...

Embodiment 2

[0120] The main part of a new oil and gas well filling system includes:

[0121] (1) Controllable flow device: The controllable flow device is composed of a particle interceptor and a flow channel; for example Figure 12 as shown, Figure 12 The particle interceptor is composed of a sleeve 12-1, and the flow channel is a hole 12-2 with a designed flow rate arranged on the base pipe.

[0122] The particle interceptor is composed of a seam cover, the seam width is 0.5mm, Figure 12 Among them, 12-2 is the designed flow channel on the base pipe. A controllable flow device is assembled at the toe end of the entry pipe string corresponding to the oil and gas well.

[0123] (2) Intercepted particles: the specific gravity of the particles is 1.0g / cm 3 , solid round particles with an average particle size of 0.4mm, the largest particle size is about 0.6mm, and the smallest particle size is about 0.2mm.

[0124] (3) Filling particles: the specific gravity is 1.0g / cm 3 , round sol...

Embodiment 3

[0133] The main part of a new oil and gas well filling system includes:

[0134] (1) Controllable flow device: The controllable flow device is composed of a particle interceptor and a flow channel; for example Figure 13 As shown, the particle interceptor is composed of a slit sleeve with a slit width of about 0.5mm, and the circulation channel is a deep hole 13-2 arranged inside the base pipe.

[0135] Such as Figure 13 As shown, deep holes 13-2 are arranged inside the base pipe , A controllable flow device is assembled at the toe end of the entry pipe string corresponding to the oil and gas well.

[0136] (2) Intercepted particles: the specific gravity of the particles is 1.0g / cm 3 , solid round particles with an average particle size of 0.4mm, the largest particle size is about 0.6mm, and the smallest particle size is about 0.2mm.

[0137] (3) Filling particles: the specific gravity is 1.05g / cm 3 , round solid particles with an average particle size of 0.15 mm. Block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com