Square conductive flexible intermediate bulk container

A container bag, square-shaped technology, applied in the field of square-shaped conductive container bags, can solve the problems of short service life, low efficiency of bulk material shipment, low efficiency, etc., achieve convenient production and use, improve shipping efficiency, and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

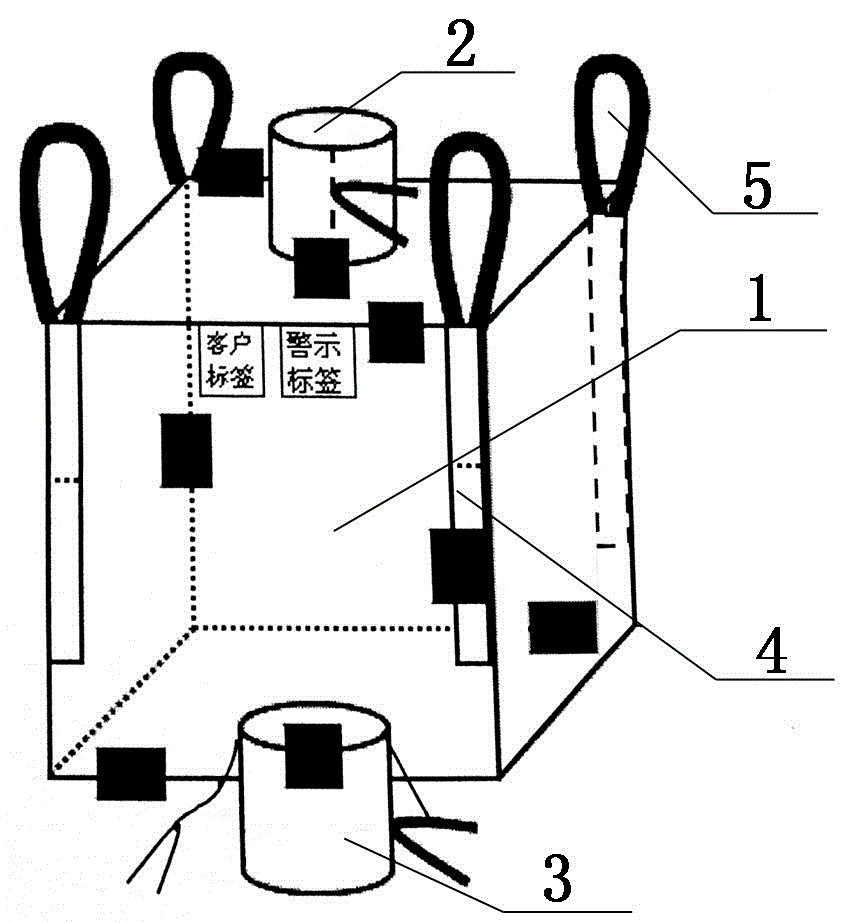

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a square conductive container bag according to the present invention includes a square bag body 1 made of a polymer material woven cloth, and the middle of the upper and lower bag surfaces of the bag body 1 is each sewn There is a feed port 2 and a discharge port 3, and the four corners of the upper bag surface of the bag body 1 are sewn with a suspension ring 5 formed by a sling 4 folded back at least along a vertical edge, and the two ends of the sling 4 Parts are sewn on the side wall of the bag body 1 from top to bottom;

[0012] The six sides of the bag body 1 are all made of conductive cloth, and the inner surface of each piece of conductive cloth is coated with a film layer; the upper material opening 2 and the lower material opening 3 are also coated with The film layer is made of conductive cloth; at least four continuous conductive wires are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com