A kind of preparation method of polyurethane modified pigment printing adhesive

A technology of polyurethane modification and pigment printing, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve the problems of complicated process, difficult industrialization, low wet rubbing fastness and rinsing color fastness, etc., to improve the reaction rate, Good hand quality and fastness to washing and soaping, which is conducive to the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

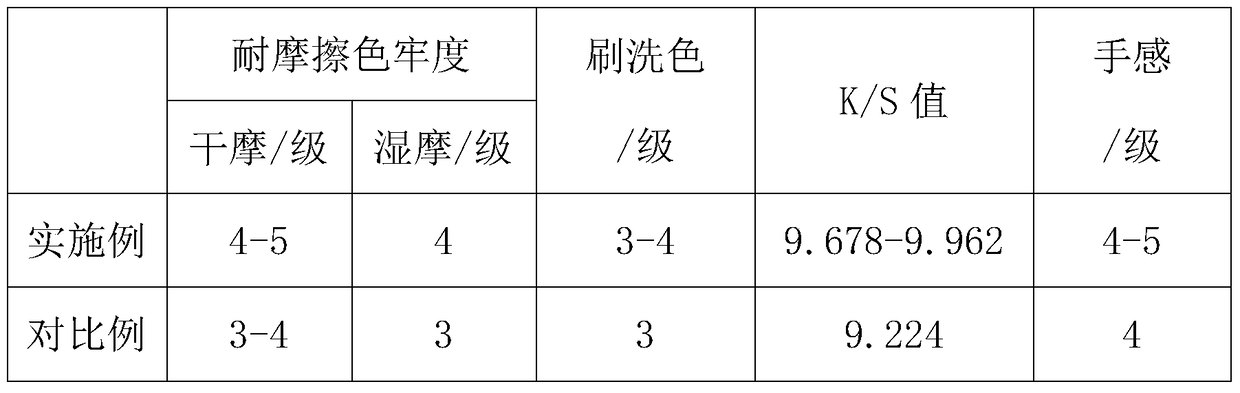

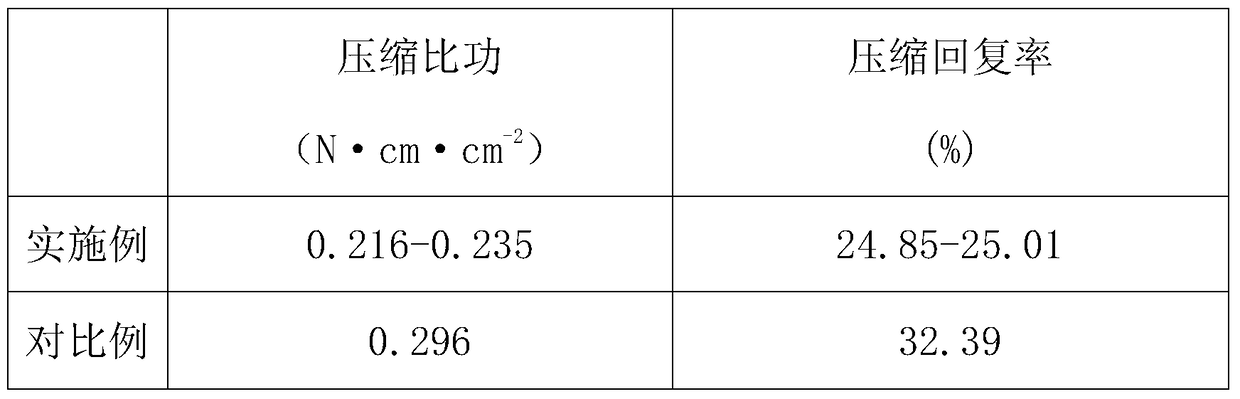

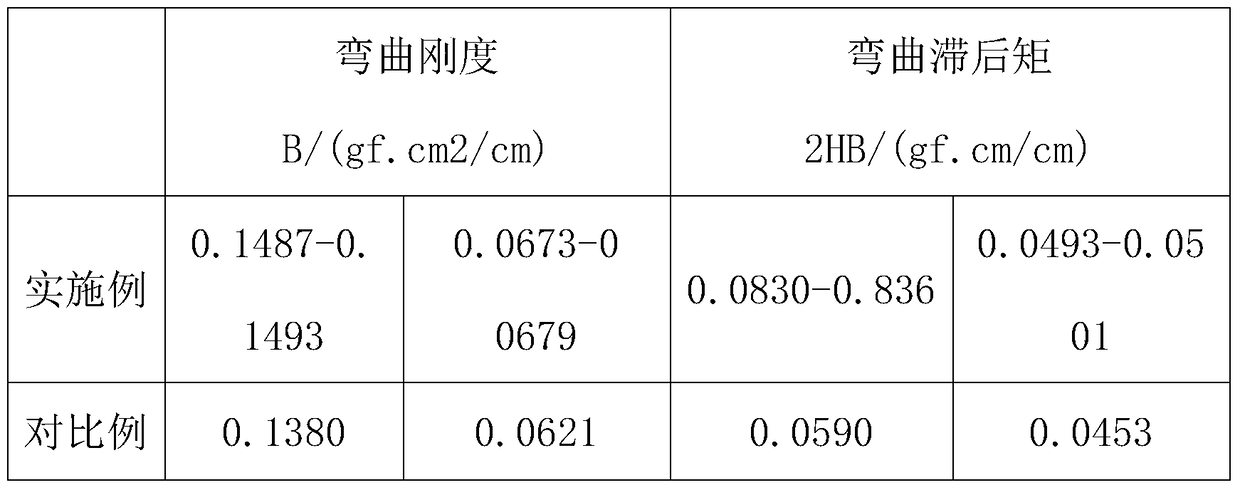

Examples

Embodiment 1

[0030] A preparation method of polyurethane modified pigment printing adhesive, comprising the following steps:

[0031] Step 1: Evaporate and dehydrate the polyether polyol with a molecular weight of 1500 at a temperature of 110°C and a vacuum pressure of 0.1MPA for 1 hour;

[0032] The second step: slowly add polyether polyol and isophorone diisocyanate into the container according to the molar ratio of 1:1.5, stir and add 0.05% volume of dibutyltin dilaurate and 0.05% volume of Acrylic acid, adjust the temperature to 65°C for 3 hours;

[0033] The third step: heating up to 80° C., adding 1% by mass of 2,2-dimethylolpropionic acid and 0.01% by mass of styrene to react for 2 hours;

[0034] Step 4: Cool down to room temperature, add triethylamine and 2,2-dimethylolpropionic acid to carry out neutralization reaction, and stir rapidly for 1 hour;

[0035] Step 5: Add the same volume of distilled water into the container and stir rapidly for 1 hour to prepare the polyurethane ...

Embodiment 2

[0037] A preparation method of polyurethane modified pigment printing adhesive, comprising the following steps:

[0038] Step 1: Evaporate and dehydrate the polyether polyol with a molecular weight of 1500 at a temperature of 115°C and a vacuum pressure of 0.1MPA for 1 hour;

[0039] The second step: slowly add polyether polyol and isophorone diisocyanate into the container according to the molar ratio of 1:1.5, stir and add 0.06% volume of dibutyltin dilaurate and 0.1% volume of Acrylic acid, adjust the temperature to 70°C for 3 hours;

[0040] The third step: heating up to 85°C, adding 2,2-dimethylolpropionic acid of 2 mass% and styrene of 0.02% mass to react for 2h;

[0041] Step 4: Cool down to room temperature, add triethylamine and 2,2-dimethylolpropionic acid to carry out neutralization reaction, and stir rapidly for 1 hour;

[0042] Step 5: Add the same volume of distilled water into the container and stir rapidly for 2 hours to prepare the polyurethane modified pigmen...

Embodiment 3

[0044] A preparation method of polyurethane modified pigment printing adhesive, comprising the following steps:

[0045] Step 1: Evaporate and dehydrate the polyether polyol with a molecular weight of 1500 at a temperature of 110°C and a vacuum pressure of 0.1MPA for 1 hour;

[0046] The second step: slowly add polyether polyol and isophorone diisocyanate into the container according to the molar ratio of 1:1.5, stir and add 0.05% volume of dibutyltin dilaurate and 0.1% volume of Acrylic acid, adjust the temperature to 65°C for 3 hours;

[0047] The third step: heating up to 85°C, adding 1% by mass of 2,2-dimethylolpropionic acid and 0.02% by mass of styrene to react for 2 hours;

[0048] Step 4: Cool down to room temperature, add triethylamine and 2,2-dimethylolpropionic acid to carry out neutralization reaction, and stir rapidly for 1 hour;

[0049] Step 5: Add the same volume of distilled water into the container and stir rapidly for 1 hour to prepare the polyurethane mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com