Method for constructing superhydrophobic coating on leather surface by layer-by-layer assembly

A super-hydrophobic coating, layer-by-layer assembly technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as limited application and easy hydrolysis, and achieve the effects of environmental friendliness, convenient operation, and improved contact angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Dilute the polymer emulsion (polyacrylate emulsion) with a solid content of 30% with water to a mass fraction of 2%, and spray it on the leather surface after dyeing, fatliquoring, cleaning, and drying, and spray 2 Times, the spraying amount is 10g / sf 2 , Dried at room temperature to form polymer latex film;

[0025] Step 2: Spray 0.5% hydrophobized silica (commercially available hydrophobized silica) ethanol dispersion on the surface of the polymer latex film, spray twice, and the spray amount is 10g / sf 2 , And placed in an oven at 30℃ to dry;

[0026] The spraying described in step 1 and step 2 are all air spraying methods, the pressure of the air compressor is 0.4 MPa, and the distance between the spray gun and the leather sample is 0.17 m.

Embodiment 2

[0028] Step 1: Dilute the polymer emulsion (polyurethane emulsion) with a solid content of 40% with water to a mass fraction of 6%, and spray it on the leather surface after dyeing, fatliquoring, cleaning, and drying, and spray twice. Spraying amount is 15g / sf 2 , Dried at room temperature to form polymer latex film;

[0029] Step 2: Spray 1.7% hydrophobized silica on the surface of the polymer latex film (after heptafluorooctyltrimethoxysilane, heptafluorooctyltriethoxysilane, tridecafluorooctyltrimethyl) Oxysilane or tridecafluorooctyltriethoxysilane modified silica) ethanol dispersion, sprayed twice, the spraying amount is 15g / sf 2 , And placed in an oven at 65℃ to dry;

[0030] The spraying described in step 1 and step 2 is air spraying, the pressure of the air compressor is 0.6 MPa, and the distance between the spray gun and the leather sample is 0.25 m.

Embodiment 3

[0032] Step 1: Dilute the polymer emulsion (epoxy resin emulsion) with a solid content of 50% with water to a mass fraction of 10%, and spray it on the leather surface after dyeing, fatliquoring, cleaning, and drying, and spray 2 Times, spraying volume is 20g / sf 2 , Dried at room temperature to form polymer latex film;

[0033] Step 2: Spray 3% hydrophobized silica (silica modified with long-chain alkyl silane with C atom number greater than or equal to 12) ethanol dispersion on the surface of polymer latex film, spray 2 Times, spraying volume is 20g / sf 2 , And placed in an oven at 100℃ to dry;

[0034] The spraying described in step 1 and step 2 are all air spraying methods, the pressure of the air compressor is 0.8MPa, and the distance between the spray gun and the leather sample is 0.33m.

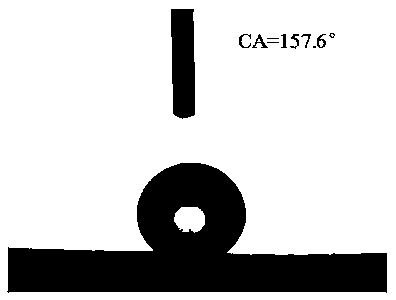

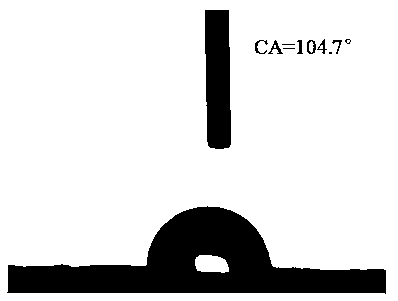

[0035] See figure 1 with figure 2 In contrast, the leather coating obtained according to the method of the present invention without changing the leather processing process has a significant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com