Bridge-cut-off aluminum-plastic co-extrusion section bar special for outside-aluminum inside-plastic doors and windows and production method thereof

A technology for broken bridge aluminum and aluminum profiles, which is applied in windows/doors, building components, buildings, etc., can solve the problems of easy aging of plastics due to ultraviolet light irradiation, high cost, and poor thermal insulation of exposed aluminum, so as to overcome the problems of ultraviolet light irradiation. Effects of aging, material cost reduction, and material cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

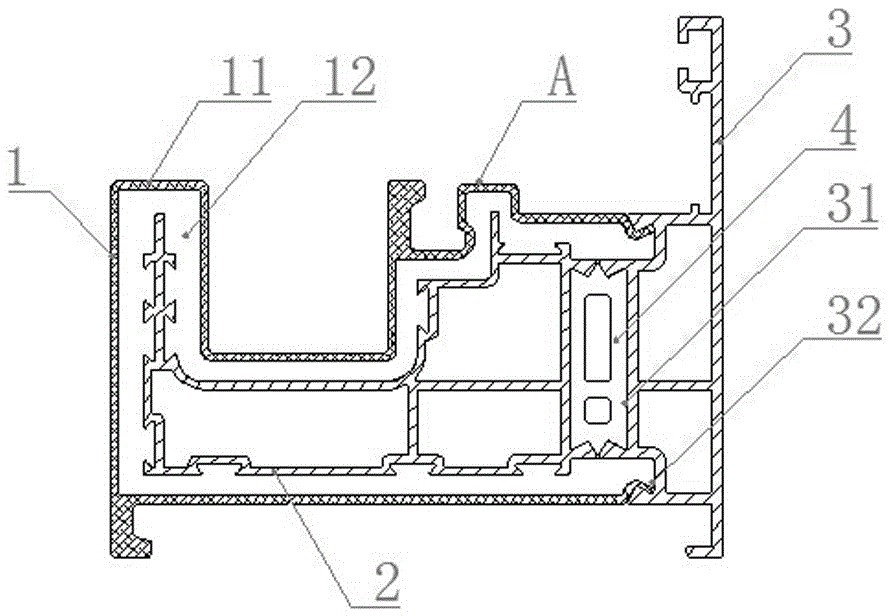

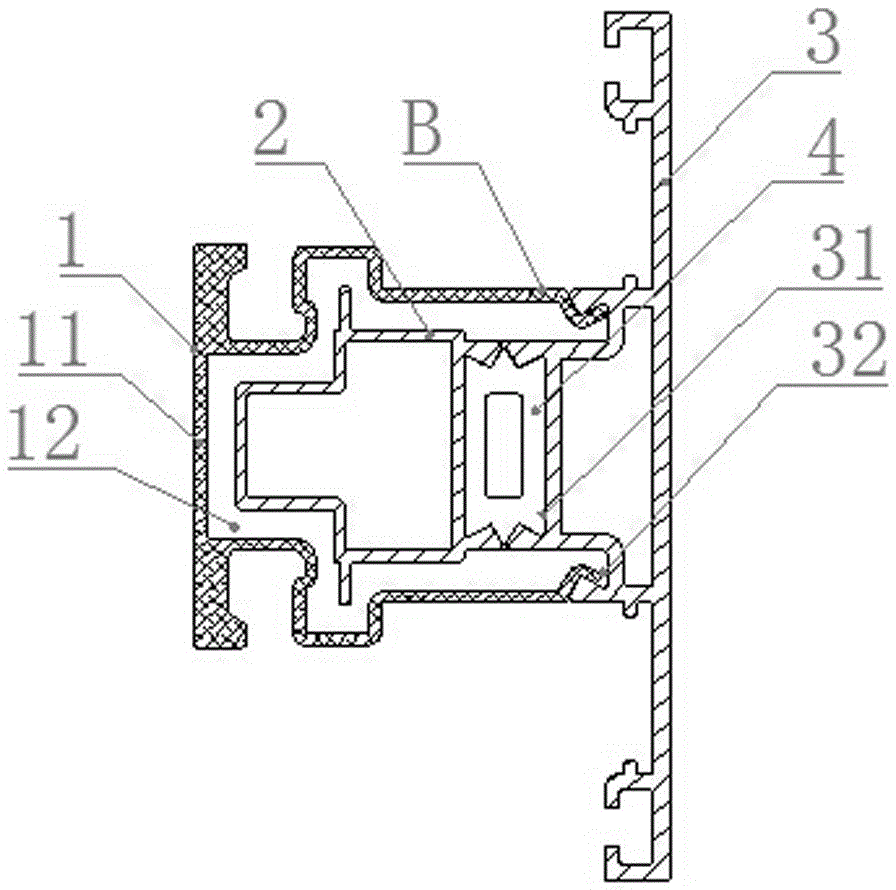

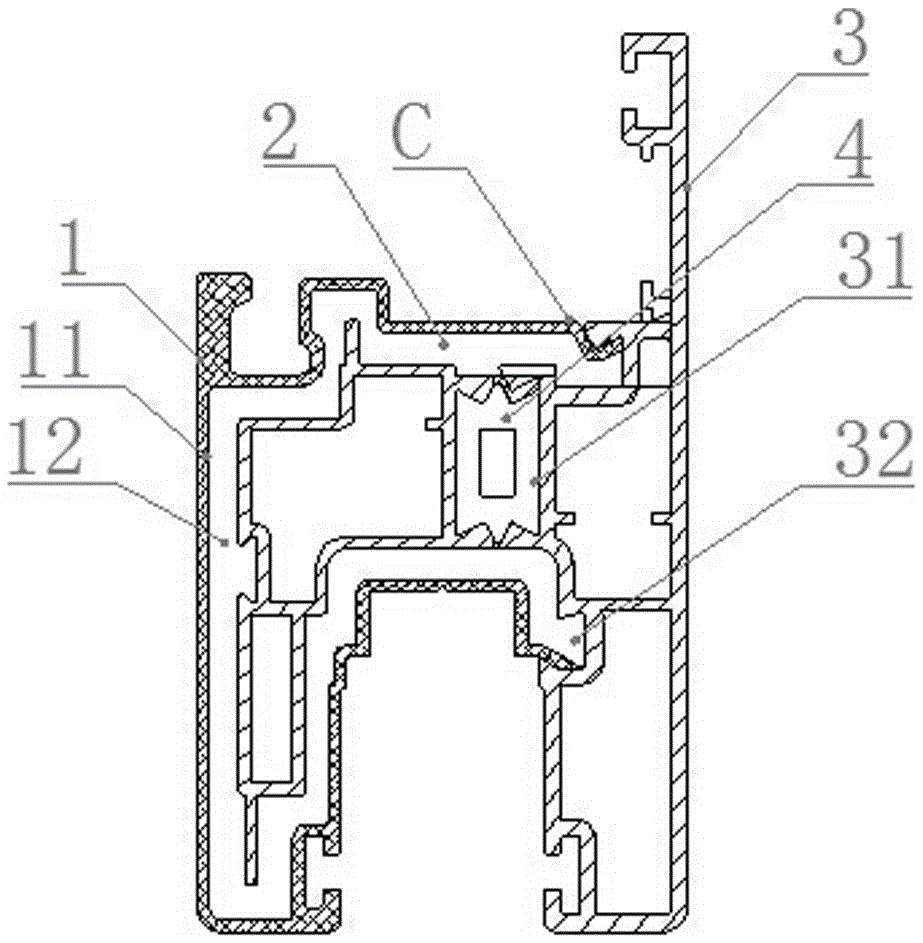

[0042] see Figure 1 to Figure 15, the special broken bridge aluminum-plastic co-extruded profile for doors and windows with outer aluminum and inner plastic of the present invention and its production method are described as follows:

[0043] 1. Types of profiles:

[0044] Whether the broken bridge aluminum-plastic co-extruded profile is a series of sliding doors and windows (such as Figure 1-Figure 5 Shown), or casement doors and windows series (such as Figure 6-Figure 14 As shown), they are divided into three types: frame, stile and fan with the same structure and different structures.

[0045] (1) Frame profile A, D: Frame profile A or D is the edge profile forming around the doors and windows. Generally, a single door and window consists of two horizontal, upper, lower and vertical left and right sides to form the peripheral squares of the door and window, such as Figure 4 and Figure 9 shown.

[0046] (2) Stile profile B, E: Stile profile B or E is used in a sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap