Pseudo-inclined variable-angle layout method for fully-mechanized mining/caving face in large-dip coal seam with variable angle

A layout method and technology of working face, which is applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as complicated contact between support and roof, poor system stability, and difficulty in roof management, so as to achieve convenient implementation, ensure stability, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

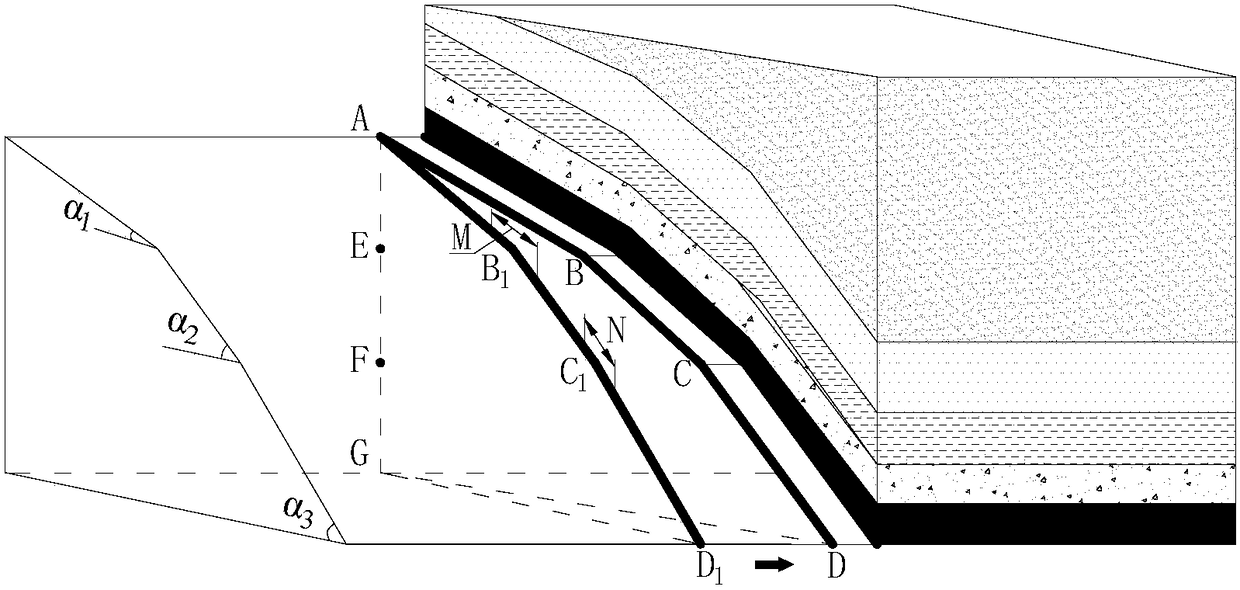

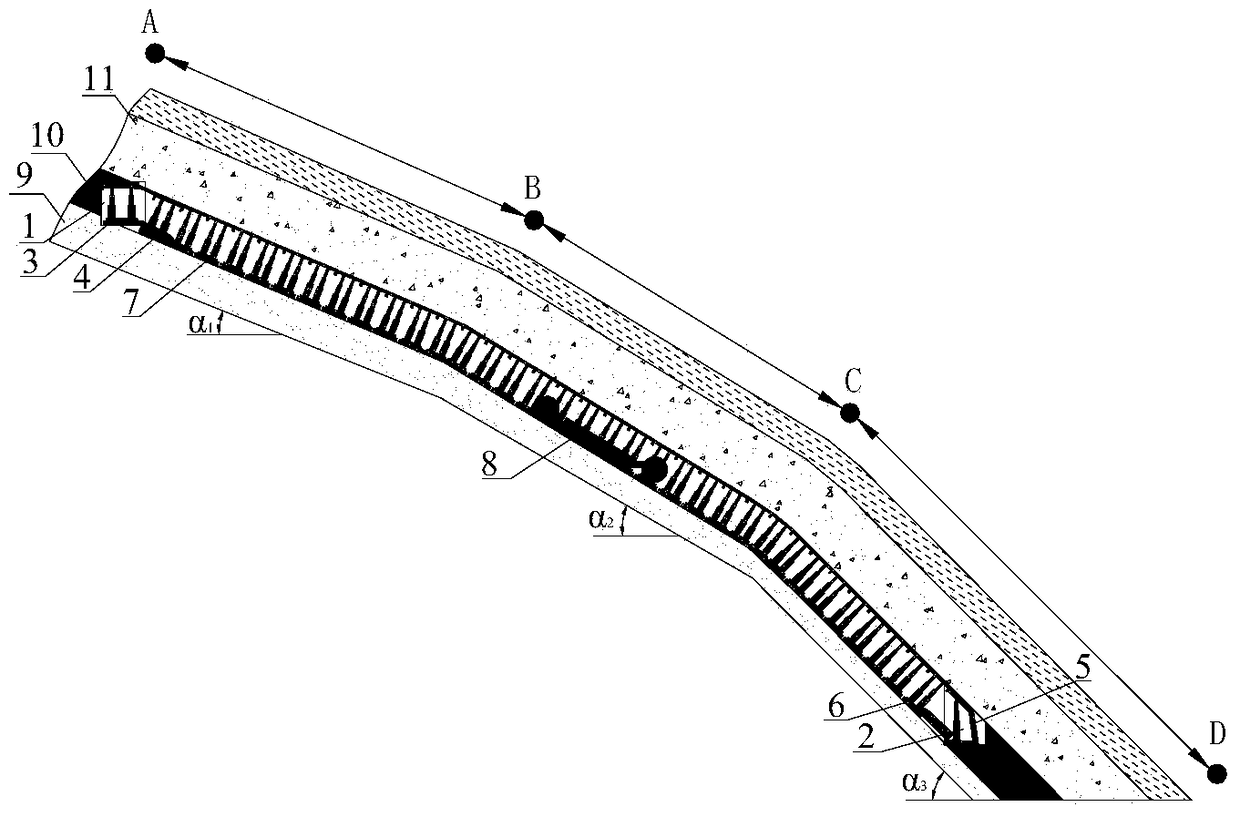

[0042] When the stratum is an anticline, the pseudo-elevation variable dip angle is arranged, refer to Figure 1 to Figure 3 .

[0043] The first step: determine the layout parameters

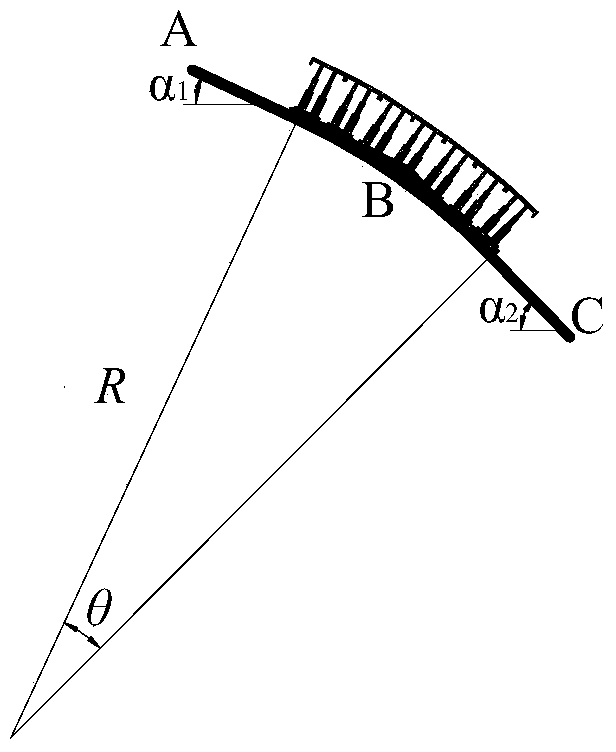

[0044] 1. Choose to change the angle to the longwall working face AB 1 C 1 D. 1 As the actual mining working face of the high-inclination coal seam, the inclination angle of the upper area of the working face is α 1 , the inclination angle of the middle area is α 2 , the inclination angle of the lower area is α 3 , α 1 2 3 , where the inclination angle α of the upper region 1 25°-35°, inclination angle α in the central area 2 35°-45°, the inclination angle α of the lower area 345°-65°.

[0045] In this embodiment, the inclination angle α of the upper region 1 is 25°, and the inclination angle α in the middle area 2 is 35°, the inclination angle α of the lower area 3 is 45°.

[0046] 2. The transition section between the upper area and the middle area is M, and the transition sec...

Embodiment 2

[0058] When the stratum is syncline, arrange the pseudo-inclination variable dip angle, refer to Figure 4 to Figure 6 .

[0059] The first step: determine the layout parameters

[0060] 1. Choose to change the angle to the longwall working face AB 1 C 1 D. 1 As the actual mining working face of the high-inclination coal seam, the inclination angle of the upper area of the working face is α 1 , the inclination angle of the middle area is α 2 , the inclination angle of the lower area is α 3 , α 1 >α 2 >α 3 , where the inclination angle α of the upper region 1 45°-65°, inclination angle α in the middle area 2 35°-45°, the inclination angle α of the lower area 3 25°-35°.

[0061] In this embodiment, the inclination angle α of the upper region 1 is 45°, and the inclination angle α in the middle area 2 is 35°, the inclination angle α of the lower area 3 is 25°.

[0062] 2. The transition section between the upper area and the middle area is M, and the transition s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com