Surrounding shell demolding mechanism

A technology of demoulding mechanism and shell, which is applied to household appliances, hollow objects, other household appliances, etc., can solve the problems of small plastic parts and no inner wall demoulding mechanism, achieve proper selection of structure, and solve the problems of mold production and structure. Simple and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0052]In order to make the above objects, features, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0053]In this embodiment, the mobile phone charger housing plastic parts will be described as an example.

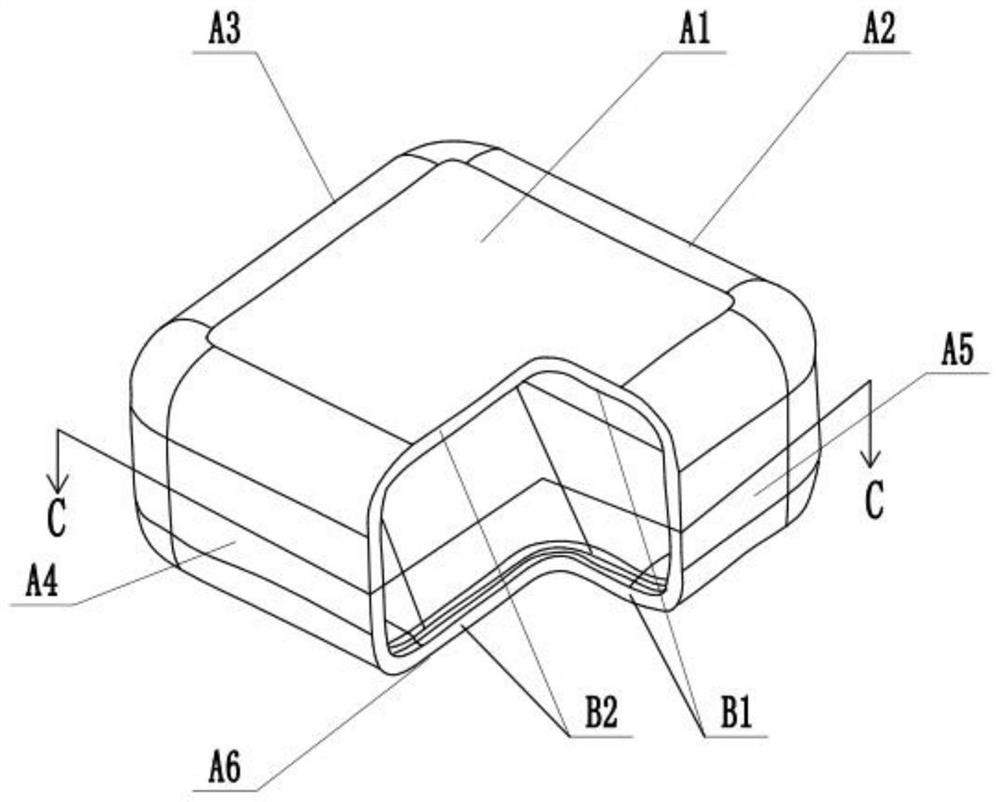

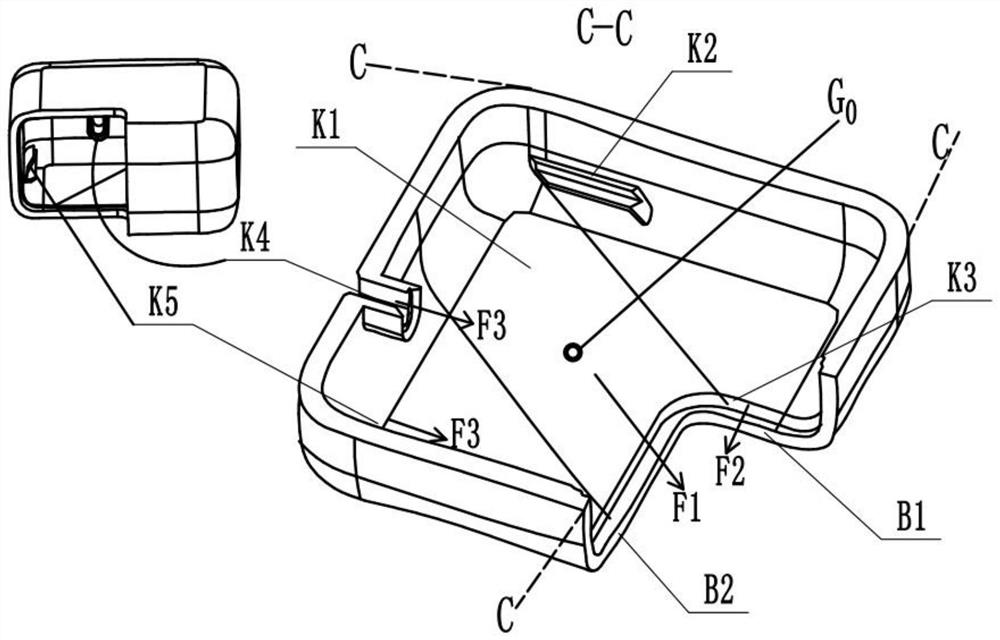

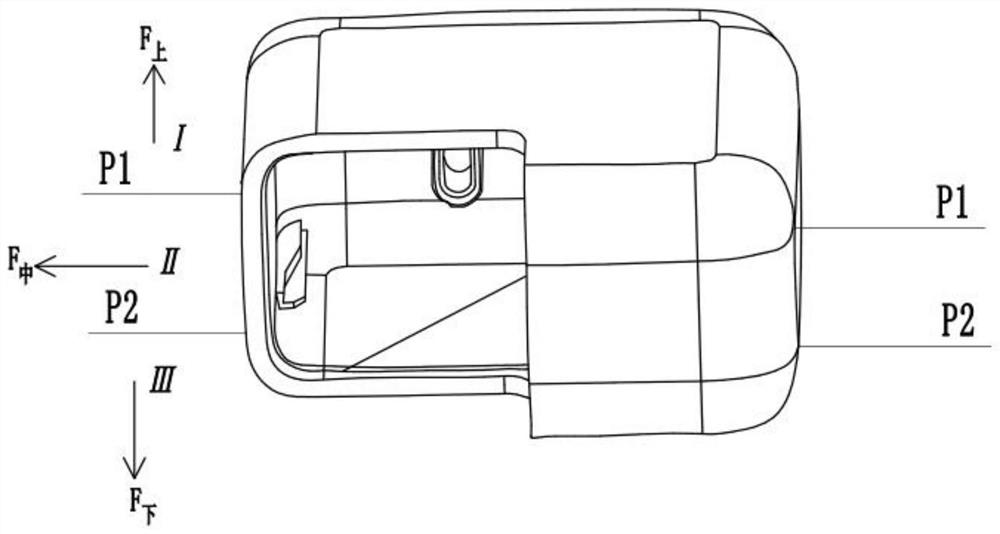

[0054]Such asfigure 1 with2As shown, the outer shape of the mobile phone charger case plastic parts is a rectangular component, and there are 5 faces of the plastic parts, and there are 5 faces of the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com