Engine exhaust throttling device and method for auxiliary braking of heavy-duty trucks

A technology for auxiliary braking and trucks, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as brake failure, safety hazards, brake failure, etc., and achieve the effect of avoiding brake failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

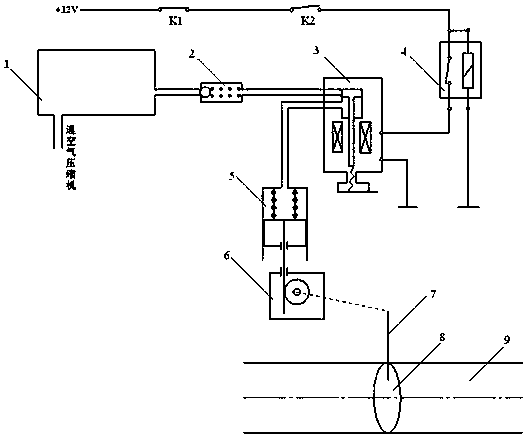

[0018] see figure 1 , the invention relates to an engine exhaust throttling device for auxiliary braking of heavy-duty trucks, the device includes an air storage tank 1, and the air storage tank 1 is connected to the column Plug mechanism 5, the plunger rod of the plunger mechanism 5 is connected with the rack of the rack and pinion transmission mechanism 6, and the central axis of the gear of the rack and pinion transmission mechanism 6 is connected with the throttle plate shaft 7, The throttle plate shaft 7 is connected with the exhaust throttle plate 8 installed in the exhaust pipe 9;

[0019] Specifically, the above-mentioned plunger mechanism 5 includes a housing, a plunger and a plunger rod. The plunger is slidably arranged in the cavity of the housing. One end of a return spring located in the cavity is connected to the top of the cavity, and the other end is connected to the column The upper surface of the plug is connected, the cavity of the housing is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com