Screw drilling tool oil seal spindle assembly

A technology of screw drilling tools and oil seals, which is applied in drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. Poor capacity, low service life of screw drilling tools, etc., to increase abrasive wear and power loss, improve lubrication effect, work efficiency and life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

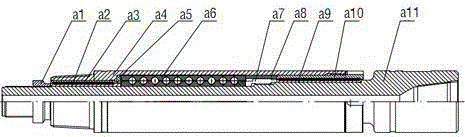

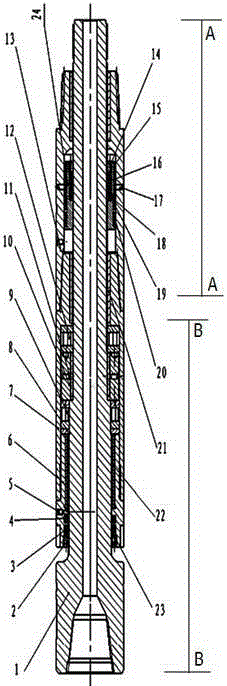

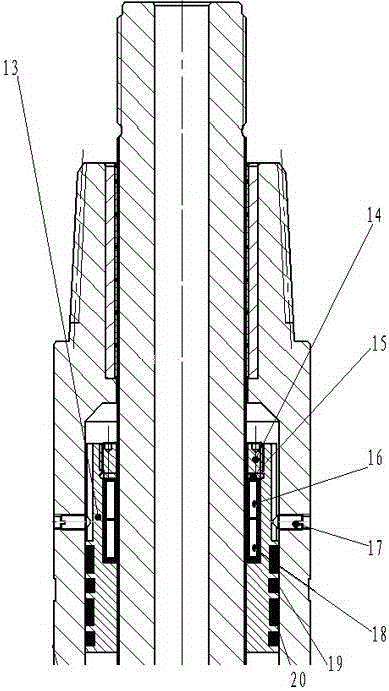

[0021] combined with Figure 1-7 , to further describe the present invention:

[0022] The present invention includes a housing part and a main shaft 1, wherein the housing part is formed by connecting the lower outer bearing housing 6, the lower housing 7 and the upper housing 13 from bottom to top, and the main shaft 1 passes through the middle of the housing part to form spindle assembly;

[0023] A first seal ring 3 and a sliding seal 4 are provided between the lower end of the lower outer bearing housing 6 and the main shaft 1, and the positioning and preload are provided by the compression nut 2 and the compression washer 23, forming a lower Partial sealing structure of the outer bearing housing ensures the sealing between the lower end of the lower outer bearing housing 6 and the main shaft 1;

[0024] The upper end of the lower outer bearing housing 6 is installed with the lower sliding bearing 22, the upper end of the lower housing 7 is installed with the upper slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com