A Method of Reducing Bearing Friction Coefficient by Changing Lubricating Oil Under Variable Load

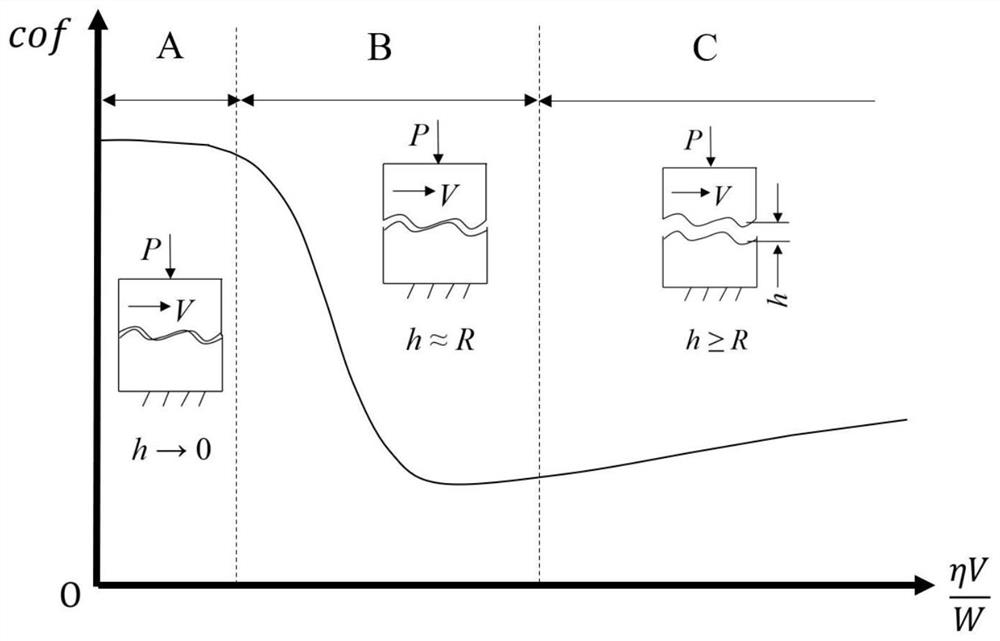

A friction coefficient and bearing friction technology, applied in special data processing applications, geometric CAD, etc., can solve problems such as limited ability of good lubrication, increase in friction coefficient, change in lubrication state, etc., to achieve low manufacturing cost and reduce friction power consumption. , The effect of reducing bearing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

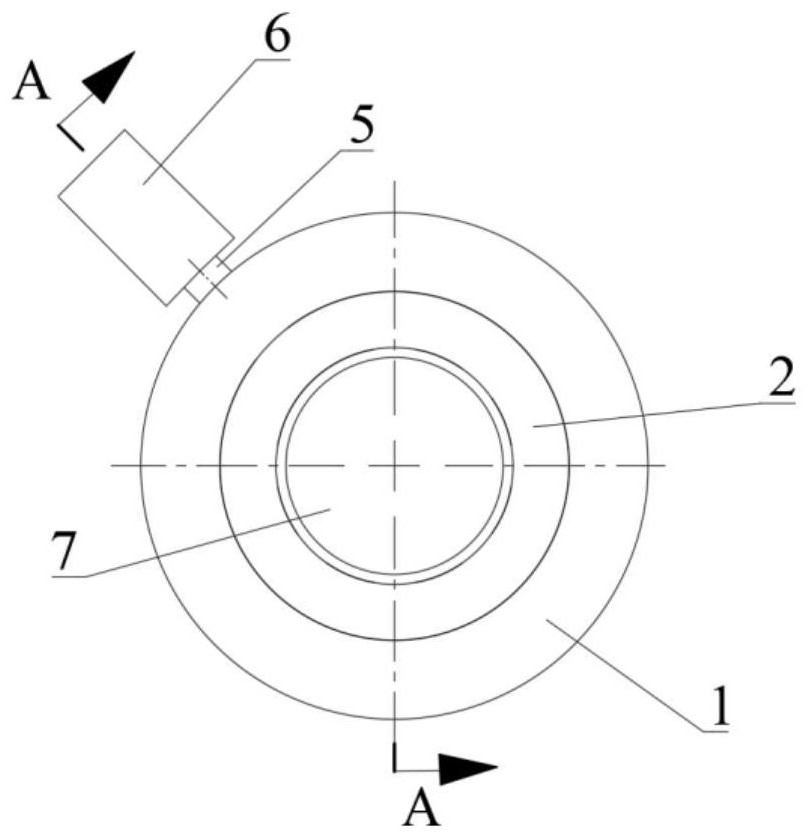

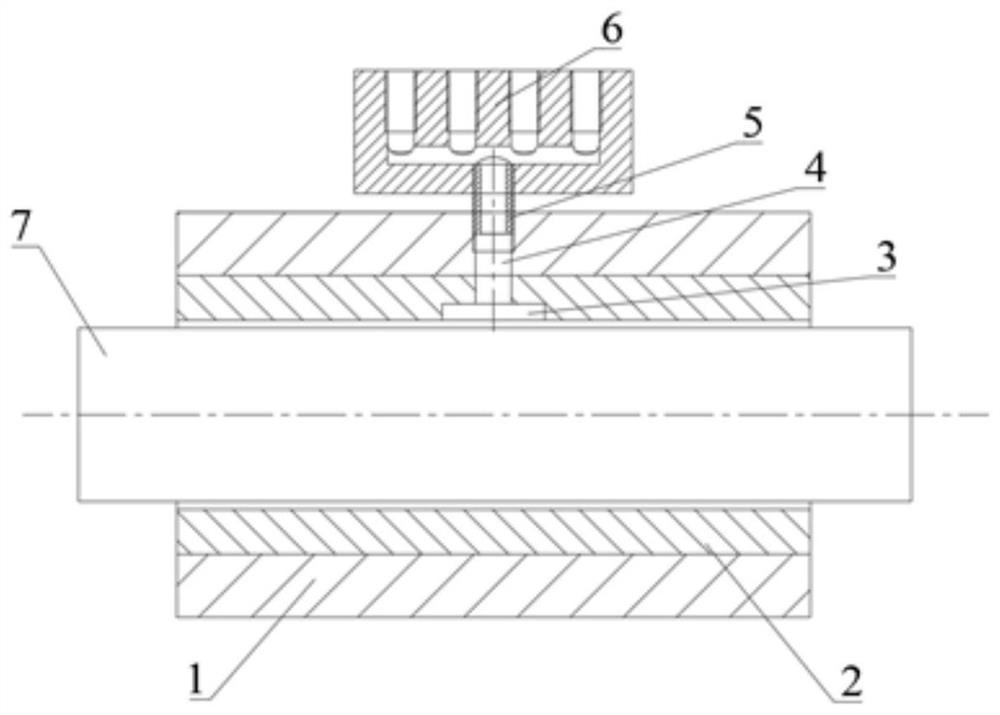

[0032] The method of reducing the bearing friction coefficient by changing the lubricating oil involved in this embodiment is realized by installing an oil drain distributor 6 on a common commercially available sliding bearing to form an oil-lubricated sliding bearing, and the oil-lubricated sliding bearing The main structure includes: bearing seat 1, bushing 2, oil pool 3, oil injection hole 4, connector 5, oil drain distributor 6 and rotating shaft 7; bearing seat 1 is used to fix bushing 2; bushing 2 is processed with Oil injection hole 4, the oil injection hole 4 is a cylindrical structure extending obliquely, the upper end of the oil injection hole 4 is connected with the oil drain distributor 6 through the connecting piece 5, and the lower end of the oil injection hole 4 extends into the bushing 2; the oil pool 3 is located on the inner surface of the bushing 2 , the oil pool 3 is a cavity structure for oil storage, the oil pool 3 communicates with the oil injection hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com