Gas turbine engine

A technology of gas turbines and gas turbines, which is applied in the direction of gas turbine devices, machines/engines, non-variable engines, etc., can solve the problems of bulky, long gas turbine engines, etc., and achieve high efficiency, low internal power loss, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description may use terms such as "horizontal", "vertical", "lateral", "front and rear", "upper and lower", "upper", "lower", "inner", "outer", "inward" forward", "backward", etc. These terms generally refer to the view and orientation as shown in the drawings and are associated with normal use of the invention. The terminology is for the convenience of the reader only and should not be limiting.

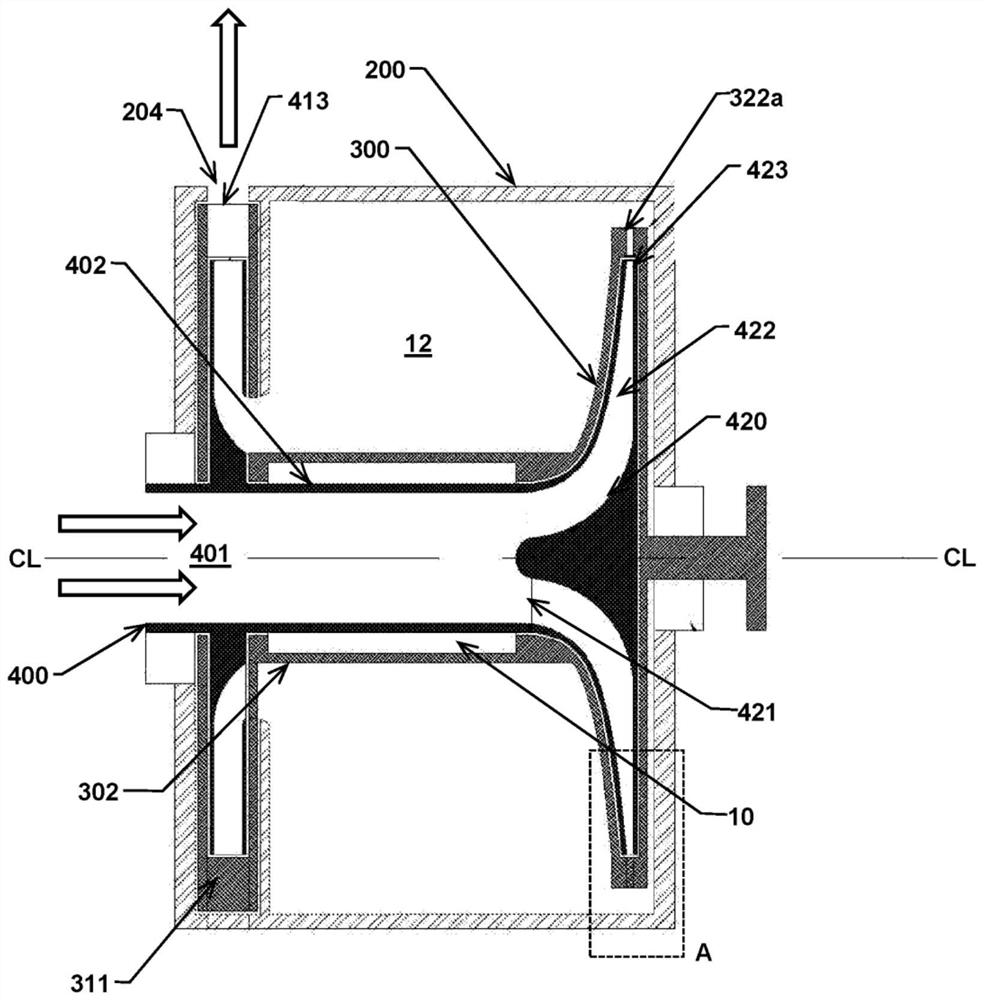

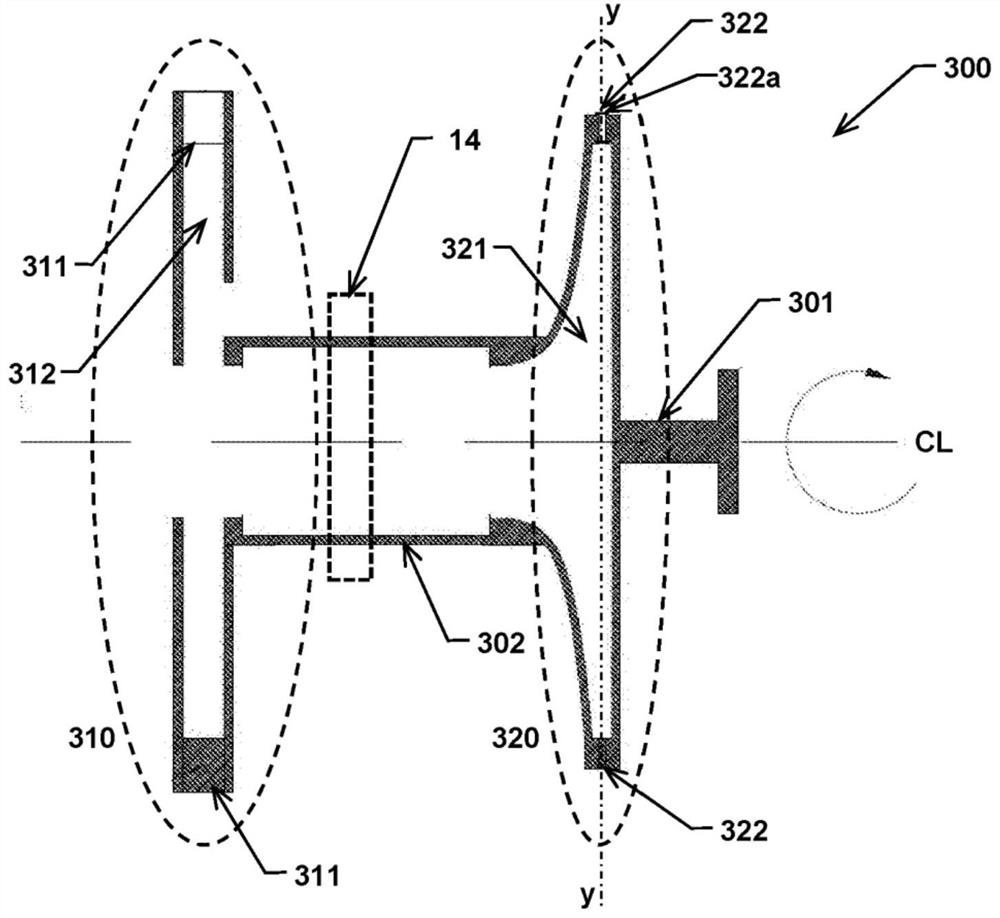

[0023] First refer to figure 1 , a gas turbine engine according to the present invention generally comprises the following three units nested within each other and arranged around a common axis of rotation CL: a power output turbine unit (POT) 300 rotatably arranged inside the outer casing unit 200 and a rotatable A compressor turbine unit (CTU) 400 is arranged in rotation inside the POT 300 . In the following, the compressor turbo unit (CTU) is also referred to as the first turbo unit 400 and the power output turbo unit (POT) is also referred to as the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com