A commercial vehicle hydraulic automatic transmission integrated with an electronically controlled hydraulic retarder

A technology of automatic transmission and hydraulic retarder, which is applied in the direction of transmission device, fluid transmission device, belt/chain/gear, etc., and can solve the problems of high failure rate and short service life of clutches and brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific examples of this invention are described below, and the detailed structure refers to the accompanying drawings.

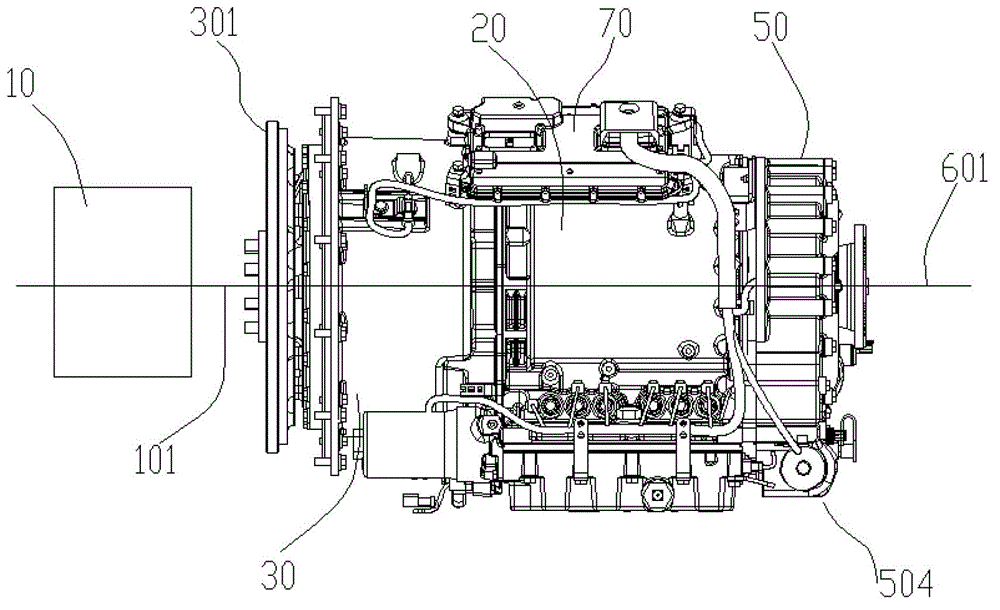

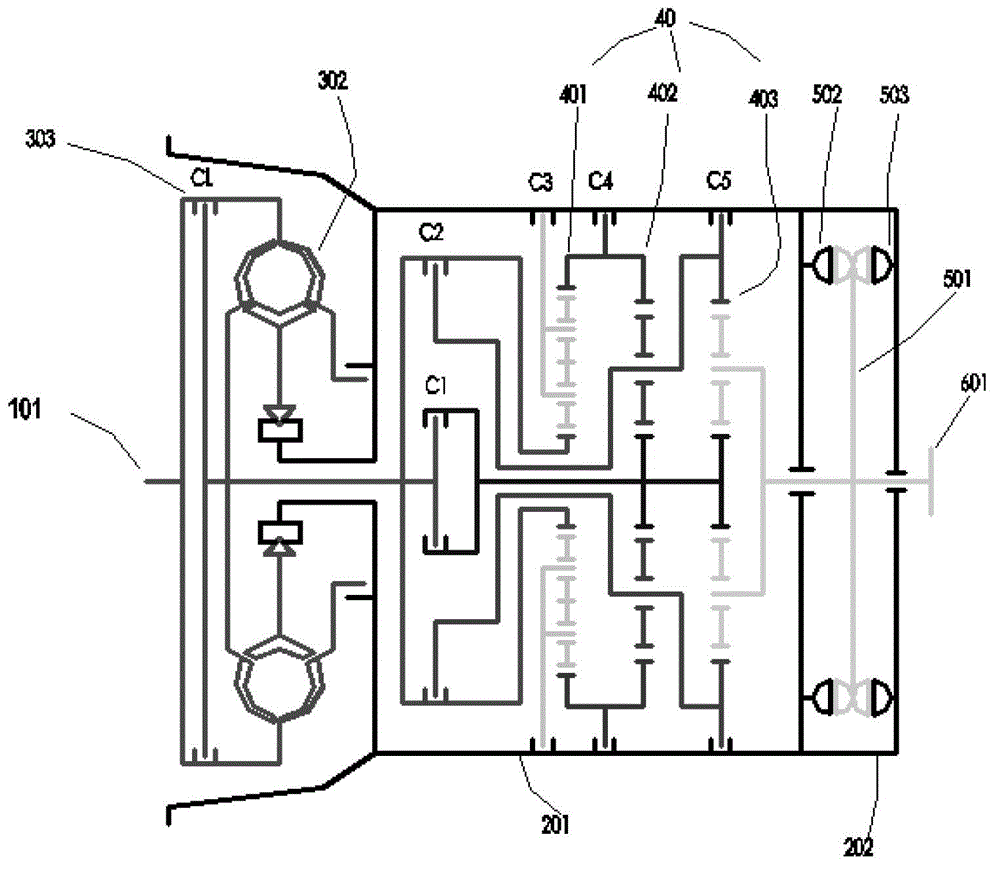

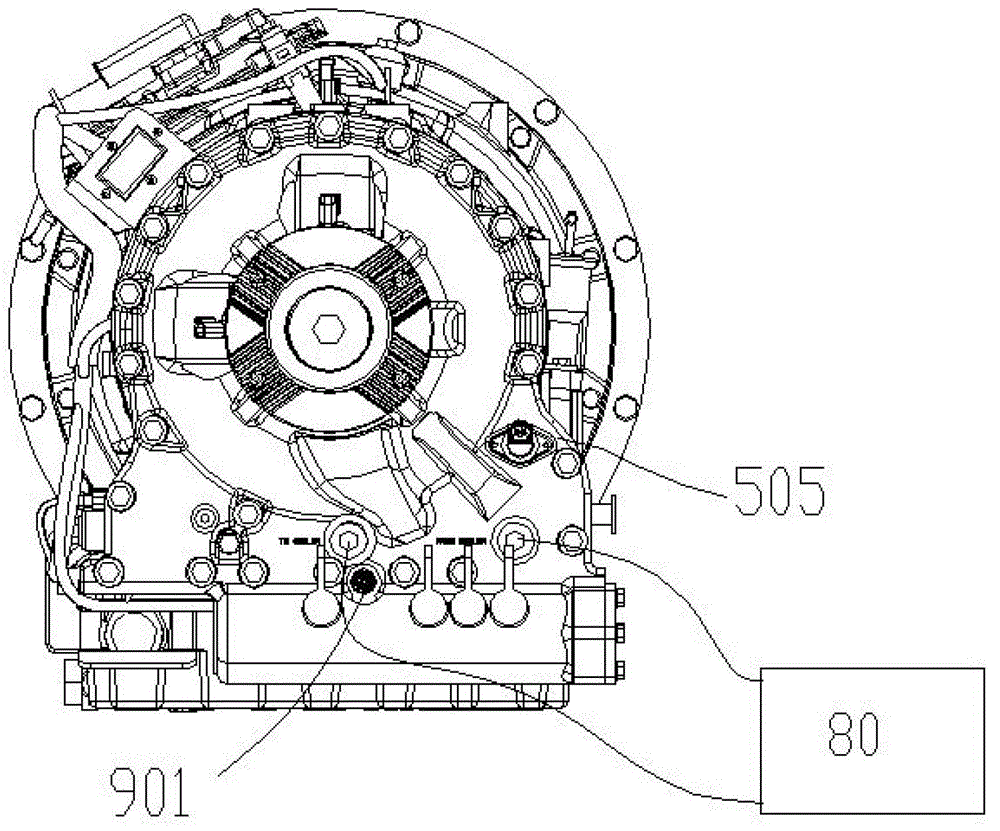

[0029] Such as figure 1As shown, the commercial vehicle hydraulic automatic transmission integrated with the electronically controlled hydraulic retarder is connected to an automatic transmission body 20 on the input shaft 101 of the engine 10, and an input connecting plate 301 is arranged on the front end of the automatic transmission body 20 , the power input device 30, an electronic control system 70 is established above the automatic transmission body 20, and a hydraulic torque converter 302 is established in the power input device 30 (see figure 2 ), a hydraulic retarder 50, a hydraulic valve group 504 and a temperature sensor 901 are also provided at the rear of the automatic transmission body 20, and the oil cooler 80 is connected by an oil connection pipe (see image 3 ).

[0030] Such as figure 2 Shown is a transmission housing 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com