Heat exchange pipe

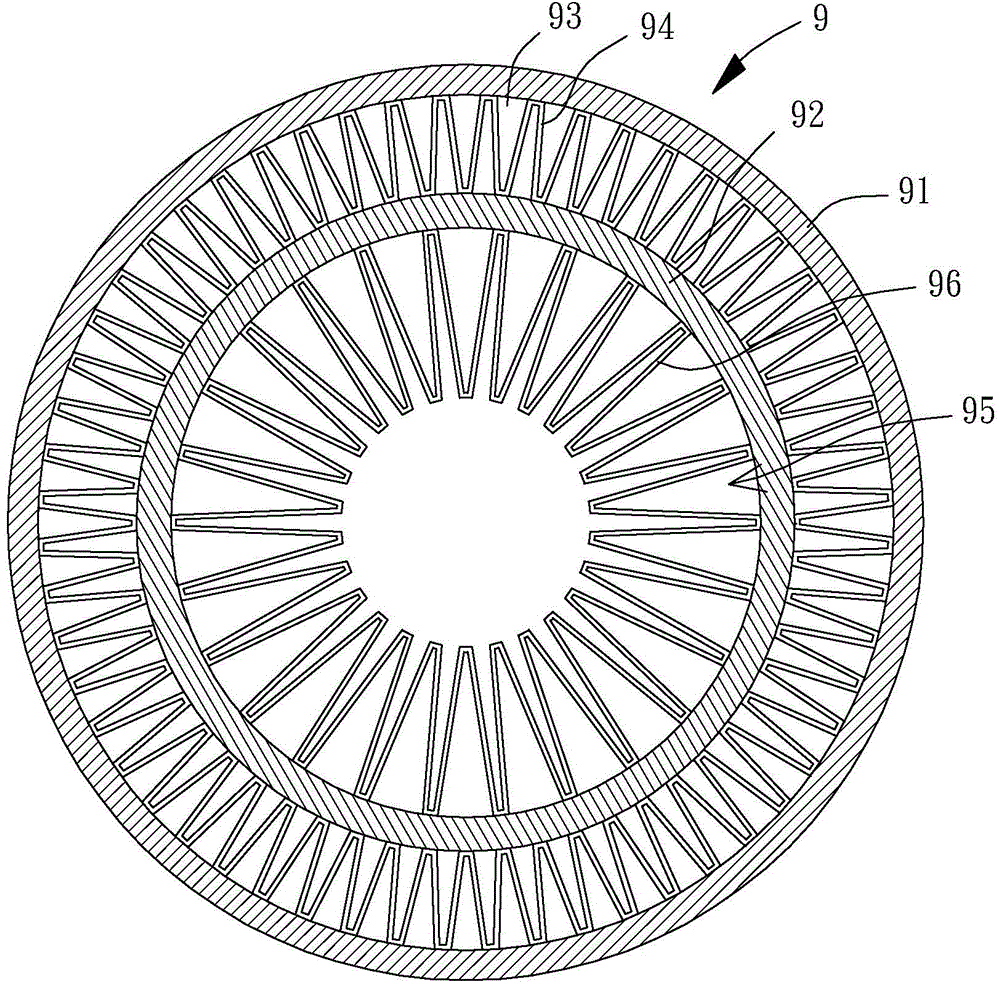

A technology of heat exchange tubes and draft tubes, applied in heat exchange equipment, tubular elements, heat transfer modification, etc., which can solve the adverse effects of heat exchange tubes 9 on heat exchange effects, poor heat exchange effects of heat exchange tubes 9, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be described in detail below together with the accompanying drawings.

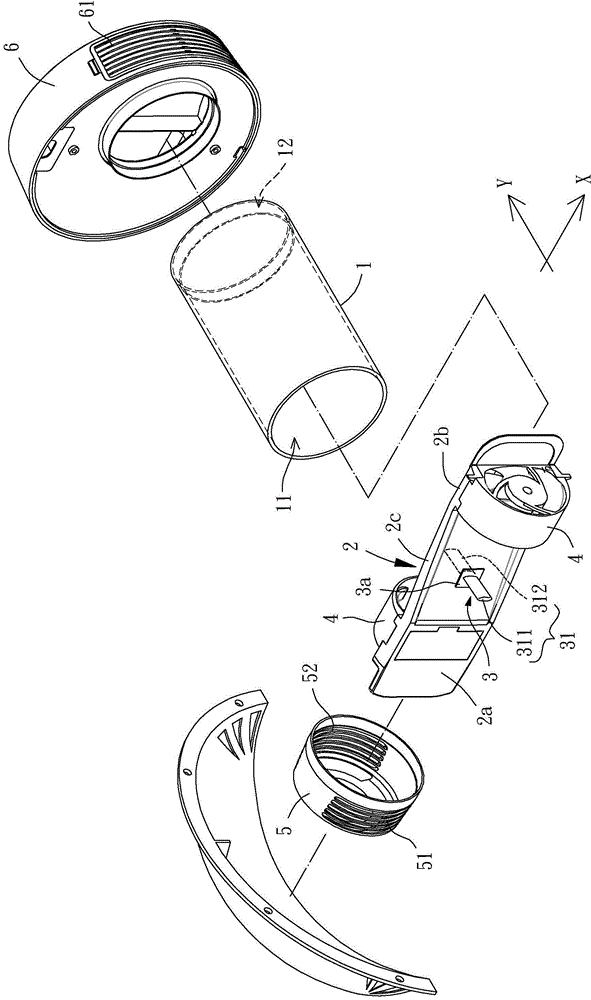

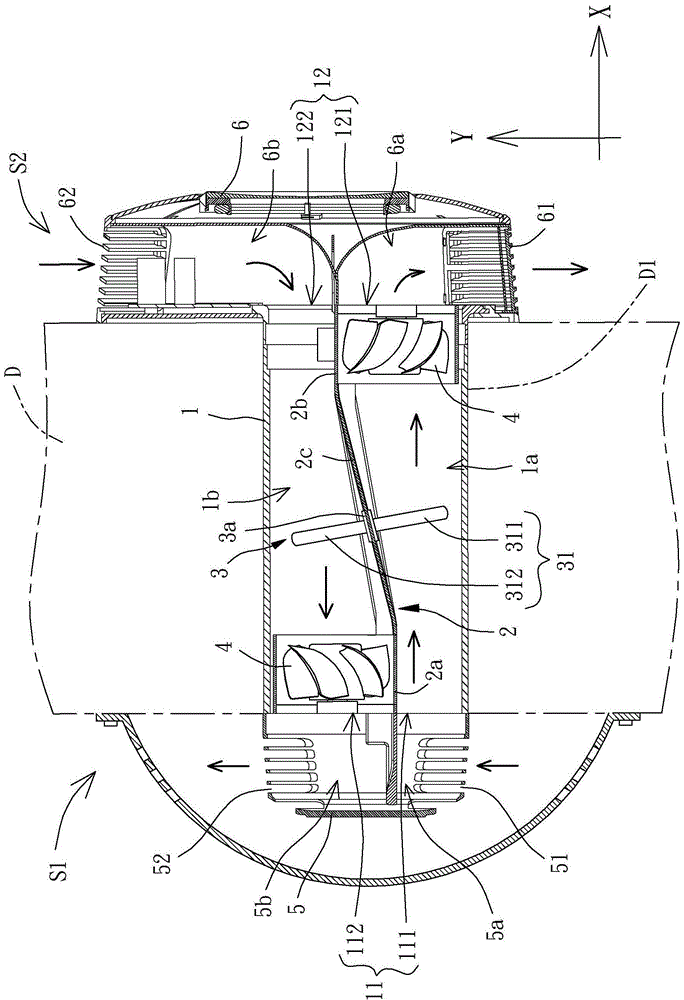

[0069] Please refer to figure 2 and image 3 As shown, the heat exchange tube in the first embodiment of the present invention is used to install on a spacer D, one side of the spacer D is an external space S1, and the opposite side of the spacer D is an inner space S1. Space S2. Wherein, the heat exchange tube includes a flow guide tube 1 , a separator 2 and at least one heat conducting member 3 . The duct 1 is installed in a through hole D1 of the spacer D, the spacer 2 is disposed inside the duct 1 , and the at least one heat conducting element 3 passes through the spacer 2 .

[0070] Under the premise of having the function of allowing various fluids (gas or liquid) to circulate, the guide tube 1 can use various hollow cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com